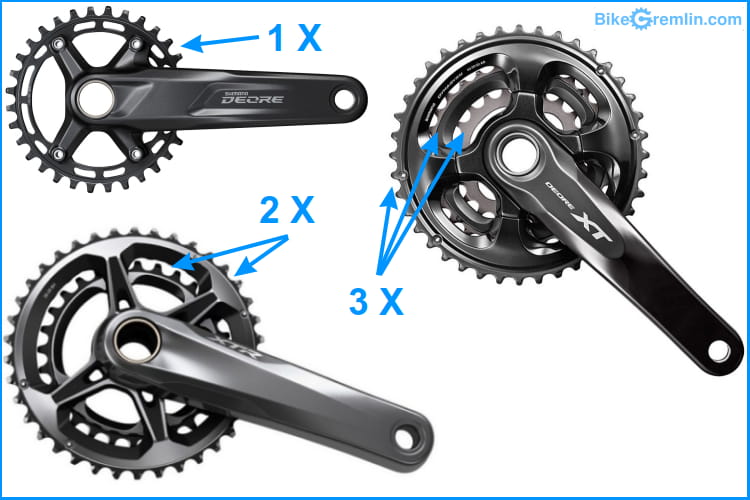

The cycling industry, mostly for marketing reasons, moves towards an ever-increasing “number of speeds” at the back. However, there is also a trend of having fewer front chainrings. First, the triples were extinct from high-end groupsets of big manufacturers, then they came for the doubles… 🙂

Today’s modern thing is the 1x – bicycle groupsets with only one front chainring. SRAM was the first to announce “the death of the front derailleur” when they made the first 1x groupset, while other manufacturers joined the race. This post will give an objective overview of 1x system pros and cons, compared to 2x (double), and 3x (triple) systems, so you could easily decide whether 1x is an optimal choice for You.

When “weighing” pros and cons, it is important to note that, while they are objective, their significance depends on particular cyclist’s priorities and riding conditions, even preferences, budget etc. Likewise, the number of pros and cons is irrelevant – it matters how much they affect performance, which entirely depends on riding conditions, as will be explained. In those terms, at the end of this post I’ll give an overview of some typical cases and what I think is the optimal choice for each, based on my knowledge and experience. Still, it’s best to weigh the pros and cons personally and decide for and by yourself what works for you.

Table Of Contents (TOC):

- Pros of 1x systems

- Cons of 1x systems

- Further differences

3.1. Large gear ratio “jumps”

3.2. Overlapped gear ratios

3.3. More rear sprockets = weaker wheel

3.4. Ground clearance

3.5. Total number of teeth for a given gear ratio

3.6. Chain line and cross chaining - Typical cases – when is which system an optimal choice

1. Pros of 1x systems

- Lower overall groupset mass (“weight”) – there’s no front shifter and derailleur, only one front chainring, no front shifter cables/housing.

- Simpler shifting – only one (rear) shifter, up-down, faster-slower.

- Better overall aerodynamics – the effect is very, very small, but for time-trial, rear derailleur is “tucked” behind riders’s legs, while extra front chainrings do create some, slight additional air drag. Yes, it sounds almost ridiculous, but for a TT trial, it might just make a split-second difference (all else having been made as aero as possible – helmet, clothes, frame, wheels, riding posture…).

- No problems with the front derailleur – when riding through sticky mud, it can pile up on the front derailleur, creating drag on the rear wheel and also hampering front derailleur operation. Rear derailleur is away from the tyre and less likely to get soaked in mud.

- Gives more freedom in frame design – important for full suspension off road bicycles. This leaves more room for wider tyres and rear suspension connecting linkages.

- Less chain drop on off-road riding – while well set up multi-chainring system doesn’t drop the chain every day, it can be said that modern 1x systems are a bit more robust when it comes to not dropping the chain when jumping over bumps (and shifting).

- One fewer lever at the bars – with no front shifter, there’s more room on the bars for other gadgets, such as suspension and dropper seatpost lockout levers, which are used on many modern MTBs.

2. Cons of 1x systems

- Smaller gearing ratio span – 2x and 3x systems (doubles and triples) generally give a larger gearing range, that is the difference between the “slowest” and the “fastest” gear.

- Greater adjacent gearing ratio differences (gaps) – in order to get somewhat usable gearing ratio range, tooth count difference of adjacent rear sprockets needs to be relatively high, since the “tool” for getting a wider gear range (front derailleur and multiple chainrings) is thrown away.

- Necessity for an outrageous number of rear sprockets – for the two reasons stated above, 1x systems require 11, 12, even 13 sprockets at the rear to get the sufficient gearing ratio range and “tightness” that is otherwise easily achieved using a 3×7 (7 sprocket) system.

- Shorter chain and sprocket lifetime – will be explained later.

- Higher price – generally, a good quality 1x groupset costs more than a 2x, or 3x system of similar quality.

- Greater drivetrain mechanical losses – because of more severe chain angle (cross-chaining) and fewer chainring teeth in some gear combinations.

3. Further differences

3.1. Large gear ratio “jumps”

Systems with multiple front chainrings allow for large changes in gear ratio by doing only one front shift. With 1x systems, this is not present.

With modern “compact” (50-34 toothed) double cranks this can be a problem. Especially if using common 11-28 cassettes (and the like). For riding on flats, 50 is often too large, while 34 is too small. Rider ends up riding severely cross chained most of the time.

With standard doubles (53-39 for road, or 26-36 for MTB), this is not a problem. With triples even less so. There you can usually find an optimal chainring for climbs, flats and downhills, without much cross chaining. In this situation, greater gear ratio change when shifting up front is often beneficial. When starting going up a hill, one front shift gives a significantly “easier” gearing, while fine tuning can be achieved during the climb with rear shifts. Same goes for reaching a hill top – one front shift puts you in a flat/downhill gearing range rather quickly.

So, large “jumps” are not always a bad thing, as some advocates of 1x systems claim.

3.2. Overlapped gear ratios

Often used argument in favour of 1x systems is that “double and triple systems have a lot of double (overlapped) gears, with only about 10-15 really different gear ratios).” This is used in a context that, for example, 2×10 doesn’t offer 20 different gear ratios as if it’s some kind of fraud.

Modern “compact” double cranks, with their large difference in chainring tooth count have very few overlapped gears, but that precisely is their main flaw, as explained in chapter 3.1. They do give a wider gear ratio range, but at the cost of more cross chaining and less practical shifting. Trying to emulate a triple with only two chainrings.

Standard doubles and triples have more overlapped gear ratios. For example a combination of 53 teeth up front and 19 teeth at the rear, gives approximately the same gear ratio as 39-14 combination. If a hill climb is approached, one can ride 39 up front, then make smaller adjustments by shifting at the rear as the climb starts. If riding on a flat, or expecting a downhill, one can use the big ring up front (53), making smaller adjustments with rear shifts. The lack of these overlapped gears is the main nuisance people have with compact doubles.

1x systems have a slight advantage here – no need for planning, or thinking ahead, just shifting up and down. Price paid for that are the 1x systems cons noted in this post.

3.3. More rear sprockets = weaker wheel

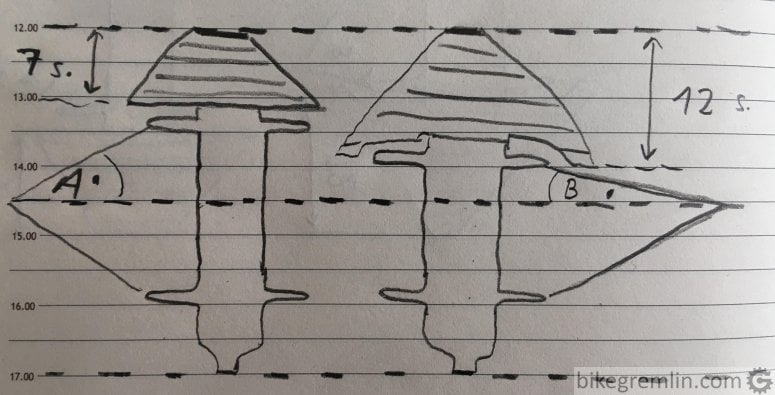

Sketch 1 is used to demonstrate what I mean:

Sketch 1

The sketch is exaggerated to show what the problem is. Angle that right hand spokes make (A and B). Cassette with more sprockets ends up taking more space, being wider and requires either a wider overall hub (which is limited for most bikes), or weaker wheel due to very sharp angle of right hand spokes. Such wheels can’t take nearly as much lateral load coming from the right hand side. Also, spoke tension differences between left and right hand side spokes are huge, which makes other problems, mostly resulting in a wheel that is less strong and less durable.

7 speeds at the rear has been phased out by manufacturers – who would want a strong, long lasting wheel with cheap components? Not the manufacturers.

Hubs for 8 to 10 speeds (and 11 speed MTB, but not road) have slightly worse right hand spoke angle.

12 speed hubs (and 11 speed road hubs) are even worse.

All this while modern hubs for hard off road riding conditions are made up to 157 mm width! Which makes frame design very difficult, since rear chainstays have to be wide, without pedals (rider’s legs) being too widely placed and without hitting the chainstays at the same time.

1x systems can’t provide useful gear ratio range or “tightness” without at least 11 sprockets – preferably 12, 13… 14? Draw your own conclusion.

3.4. Ground clearance

Same maximum gear ratio can be achieved using a 36 tooth chainring and 12 tooth sprocket, as with a 30-10 combination. Since 30 T chainring has a smaller diameter, ground clearance of such bicycle will be greater than of the one using a 36 T chainring. Where that is important, this is a logical choice (off road). It needs to be said that old MTBs had smaller 26″ wheels and triple chainrings and still got everywhere – now they use standard 28″ wheels (labelled 29″ when placed on a MTB) and clearance has become a problem somehow?

3.5. Total number of teeth for a given gear ratio

In addition to the example from the previous chapter, another one would be that achieving lowest gear ratio of a 30-45 combination would require a 54 toothed largest rear sprocket if used with a 36 toothed cranks. This explains why 1x drivetrains have required having a smallest sprocket of only 10 (or even fewer) teeth. so that a decent top and lowest gear ratio can be achieved without outrageously large sprockets (well, 40+ teeth is outrageously large if you will, but it’s still below 50 teeth).

In the previous chapter, (questionable?) advantage of using 30-10 combination over 36-12 combination way of achieving the same gear ratio was explained (more clearance). What is the (unquestionable) downside? More mechanical losses and faster chain and chainring wear. When a chain is bent over a chainring that is too small (in these terms anything below 13 teeth is very small), there are more mechanical losses due to increased friction and chainring and chain wear is increased, because 1, or 2 teeth carry all the load.

This can be considered to be a flaw of 1x systems.

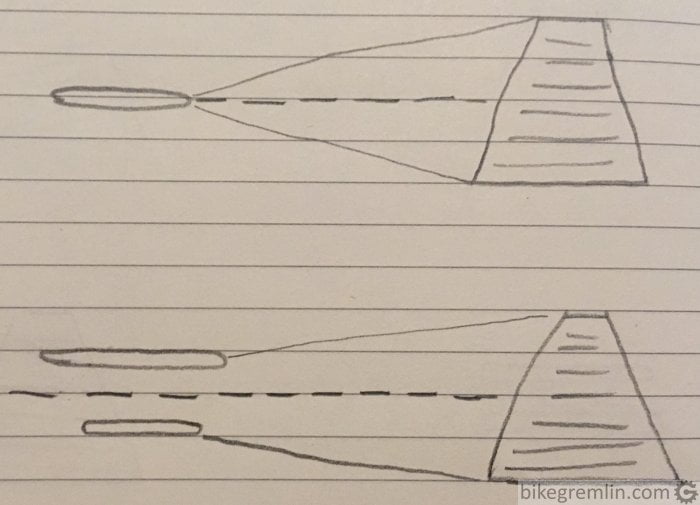

3.6. Chain line and cross chaining

When advertising 1x systems, one of arguments is also there is “no worrying about cross chaining”. With double and triple setups it is possible to severely cross chain – if using an outer most front chainring with two most inner rear sprockets (big-big combination). The same goes for small-small combination. So yes, this should be avoided and thought of when using these systems. However, it can be avoided. With 1x systems, severe chain angle in highest and lowest gear ratio is unavoidable, as shown in sketch 2.

1x system – top

2x system – bottom

Sketch 2

So it can be said that with 1x systems there’s no “worrying” about cross chaining – you get what you get, whether you like it, or not.

Greater chain angle leads to higher mechanical losses, chain is more likely to start making noise when working and both chain and chainrings will wear faster. If it’s any consolation, 1x cassettes, with the largest sprocket having 40+ teeth are more expensive, at least. 🙂

Update, May 2022:

According to these submitted patents – Shimano pat. US20170167542A1, and SRAM pat. US20170167590A1, it appears that the manufacturers are aware of this poor chainline problem of 1X systems.

Apparently, they are trying to fix the problem by designing a chainring that rotates left-right, so it can follow the line of a badly angled (crossed) chain.

I expect that in 5 to 10 years’ time, manufacturers will “discover” something like a “front derailleur” and “more than one front chainring” (ofcourse, marketing departments will surely come up with some very cool-sounding names for these!). 🙂

4. Typical cases – when is which system an optimal choice

Here I will list some typical cycling use cases/scenarios, with system that I think is an optimal choice. With a brief explanation why. Of course, it is best to choose for yourself.

- Road bike for sports/recreation riding – 2x systems give a wide gearing range, that is also tight enough, at a relatively modest price.

- Sport riding off road in lots of mud – this is where 1x makes some sense and could be a good choice, although 2x and 3x systems can also serve well.

- Loaded touring – triple (3x) without further ado. Triples offer wide gearing range with any old cassette that can be found along the way, allowing for fewer sprockets to be used for a more robust system, allowing the use of friction shifters as well.

- Grocery/errand commuting bicycle – cheapest and simplest possible. If your town is flat, single speed is perfect. If not, get the climbing gearing you need, whether it’s a 1×6, 3×8, or some other system. If theft rate is very low, it makes sense going for a higher quality, more durable (and more expensive) bikes and components.

Useful tool for choosing a cassette and/or gearing setup is “on line gear calculator“.

This concludes the list and explanation of pros and cons of 1x systems compared to 2x and 3x ones. I tried to provide all the info objectively as it is. If you have any questions, corrections, or comments, use the section below.

Help BikeGremlin

stay online & independent

This website is educational, free, objective, and not commercial

(sponsors don’t enjoy paying if you mention all the product downsides that you notice 🙂 ).

How much does a WordPress website cost?

If you find this site to be good and helpful,

and if $5 per month is what you can afford to set aside,

please consider supporting my work with a Patreon donation:

Relja Triple Novović

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/pros-and-cons-of-1x-groupsets-systems-article-comments.117/

i actually prefer one chain ring at the front and a custom 5 speed cassette at the rear,my front chain ring and crank is a single speed crank 42 teeth and in theory this should not even work but its very trouble free riding,i used alloy spacers before i put the custom 5 speed cassette on to bring the chain line into the middle of the rear cassette.i dont even have any chain guide up front,i am not a fan of extra chain rings up front,your rear cassette can be modified to climb any hills,if you cant climb hills with a 32 tooth rear cog then its time to do some more hill training,i call front triple or double chainrings chain breakers,they are just too much messing around,too much extra weight.my chain never comes of or breaks.if you are racing bike then you will probably like two or three chain rings up front

fantastic job and analysis as usual. thanks a lor Relja.

in particular I appreciated the good insight on strenght and width od rear hub.

in terms of strenght and durability, for little drops and rought terrain, which rear hub would you suggest?

I’m a fan od cup/cone bearing from Shimano. What are your ideal/stronger hub you will suggest to us?

I’ve had a good experience with Shimano Deore hubs (135 mm wide OLD).

Higher-end than those (XT, XTR, etc.) offer lower weight, but not more durability.

Lower-tier Alivio, and even Acera are also OK.

With cup and cone cups, the problems usually happen when they aren’t serviced (overhauled) regularly – once a year, or about every 5000 km, whichever comes first.

With regular service, they can last a decade, or longer.

Cartridge bearing hubs (like DT Swiss and similar) require special tools for bearing replacement, but even in case of no maintenance, won bearings get replaced, without requiring the whole hub to be replaced.

So each option has its pros and cons (I prefer cup and cone though).

Practically no manufacturer now does the ratcheting mechanism reasonably well – with just two relatively large ratchets (not sure if that’s the proper English term) placed at an asymmetric angle (not at exactly 180 degrees from each other). But, in spite of that, ratcheting mechanisms don’t get busted too quickly, they often also last for a decade or more.

Hello Relja, I’m glad Shimano Deore are ok: they will be my choiche for the rear wheel I’m planning to build.

I like service cup and cone bearing so it’s not a problem for me.

Regarding the last thing about the ratchet system, what do you mean?

Are you referring to Shimano type, the similar one like Hydra or the DT Swiss type?

By ratcheting system I mean the system used to make the cassette turn the hub when the chain pulls on it, while also allowing for any back-pedalling.

Manufacturers throw marketing terms like “small angles of re-engagement,” “many teeth for a better load transfer” etc, but I don’t think any of those make much sense technically.

Until I write a complete article on that (esoteric 🙂 ) subject, I briefly mentioned it (and included a promotional video) near the end of the 3rd chapter in my Shimano XTR M9100 groupset review.

The “trick” is – steel does elastically deform, hence, on a microscopic level, is more similar to a rubber band, than to a hard object, when put under load. That’s why only one ratchet tooth carries most of the load at any given time (unless some preload is used). Hence, fewer, larger “teeth” are a better, stronger option – but it’s become obsolete. Likewise, “only” two “teeth” that are not set at exactly 180 degrees from each other can provide for very few degrees of re-engagement, without having to use more than two “teeth” (thus allowing for them to be larger and stronger).

That at least is my opinion and analysis. I am not a mechanical engineer though, so it is possible (though probably not very probable 🙂 ) that I’m wrong.

I understand better now and I think, considering your experience, precision and intelligence, your final analysis coud be a breakthrough regarding this particualt topic: I think it was never analyzed from a non-marketing related way.

The things to consider are, (a part from the pros that can change entire wheelset like a woman changes her shoes) how much it will impair the durability a system wil smallest pawls [from Google: “a pivoted curved bar or lever whose free end engages with the teeth of a cogwheel or ratchet so that the wheel or ratchet can only turn or move one way”].

Are you familiar with DT Swiss system? [used even by ZTTO and other Chinese factories] And what about Chris Kings (and the “similar” system Scylence by Shimano -discontinued for problems in the timing needed for the engagement)

P.S. I’ll send within this night my material (pics and pdf) on these systems.

I am familiar with those systems.

DT Swiss creates no preload, in spite of all the fancy marketing talk.

Chris King RingDrive seems to work using a similar design to Shimano’s Scylence – increasing engagement preload as more torque is applied (from what I could see in the pics and tech. drawings).

The marketing team did call their roller bearings “needle bearings,” which is a standard mistake in the cycling industry. In and of itself it tells nothing for, or against the engineering behind the patent.

My “intuitive” impression is that both RingDrive and Scyclence are needlessly complicated and expensive to manufacture compared to a two-large-pawl system (for minimal, if any real gains).

As for the standard Shimano freehubs – they last OK, in spite of the design imperfection. In the worst-case scenario, there are replacement freehubs (though, and this is not very nice, they aren’t always readily available).

hi Relja,

I am looking for a 1×11 bike with 27.5 wheels and 21″ frame with preferably 130/140mm travel.

I have looked on ebay and gumtree for about a year now and cannot find any bike made in the last two years that is in good condition. Partly, this is because manufacturers are making only 1×12 drivetrains. Therefore, if I want to buy a used bike without building my own, it is most likely I will have to buy a 12 speed. According to this video https://www.youtube.com/watch?v=meZdvmJZlFc&ab_channel=LoveMTB

shimano freehubs accept 8,9,10,11 and some sram 12 speed cassettes. Does this mean the spoke angle on the driveside is the same for all shimano standard freehubs? Also, according to sheldon brown shimano “11-speed cassettes will fit only 11-speed bodies”. Can you please clarify which one is correct?

I do not know how an 11 speed cassette can fit on my 9 speed bike because the cassette is wider?

Also, according to the same video, the Sram XD driver accepts 11 and 12 speed sram cassettes. Does this mean the spoke angle is the same for 11 and 12 speed bikes with this freehub? I am thinking of buying a 12 speed bike with this freehub and putting an 11 speed cassette on it because they are cheaper. What size spacer do I need for this?

Hi Alexander,

Short answer:

11-speed XD the cassette should fit a 12-speed XD hub with the same spoke angle (a hub needn’t be replaced or altered to fit a different cassette). As far as I know, you needn’t use any spacers.

You would need a 1.85 mm spacer for fitting an XD cassette (both 11 and 12-speed ones) to an XDR freehub (the road bike version of XD).

(The same width as used to fit any 10-speed, or an 11-speed Shimano MTB cassette on an 11-speed Shimano road freehub).

Longer answer:

You can see my article about freehub compatibility and let me know if you have any questions. I’ve explained the hub versions, including the 11 and 12-speed hubs.

As for the spoke angle – 12-speed cassettes (and 11-speed MTB cassettes for that matter) are designed to fit a bit closer towards the wheel. A larger inner-most sprocket (34 teeth and more) can “avoid” hitting the spokes while being closer to the inner-most side of the wheel, compared to an 11-speed road cassette for example. Thus, the spoke angle isn’t much (any?) worse compared to the 8-9-10 speed freehubs. Not sure how well I’ve explained this – let me know if you have any more questions. 🙂

Relja