It is a common debate among cyclists (and mechanics) which is the best bicycle bearing grease – for use in hub, or steerer, brake pivot etc. bearings. Some swear by the old “axle grease” that “… my grandfather / father used …” Others recommend silicone, Teflon, graphite grease and so on. This post explains important characteristics of various greases in terms of lubricating bicycle bearings.

First there will be a few words about basic construction of bicycle bearings, lubrication requirements and types of loads that bicycle bearings take. Type of bearings and loads it takes are an important factor when selecting lubricants. Then basic characteristics of greases will be explained – in general, with standards for labelling greases explained (so that label can be understood when shopping for grease). Finally, an overview of most commercial greases types available, with advantages and disadvantages for bicycle bearing lubrication use. For simple, non-technical recommendations, look at this post: The best bicycle bearings grease. Related posts are explaininig: Bicycle hub overhaul procedure and Bicycle bearing types and designs.

Note: for mounting things (bolts, seatposts, handlebars etc.) – that is for things that are not made to slide when used, many people use grease, while it is preferable to use anti-seize / mounting pastes (as explained in that linked article). This post deals with greases in terms of lubrication primarily.

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

Table Of Contents (T.O.C.):

0. Disclaimer

1. The loads bicycle bearings take

2. Oil as a bearing lubricant

3. Greases

. 3.1. Attributes that bicycle bearing grease should have

. 3.1.1. Crit. 1. working temperature range

. 3.1.2. Crit. 2. corrosion protection

. 3.1.3. Crit. 3. water washout resistance (ISO 6743-9 E +)

. 3.1.4. Crit. 4. compatibility

. 3.1.5. Crit. 5. keeping stable structure

. 3.1.6. Crit. 6. 4 ball weld over 1000 N

. 3.1.7. Crit. 7. low price

. 3.2. Grease types division

. 3.2.1. According to base oil type

. 3.2.2. According to thickener type

. 3.2.3. According to intended use area

. 3.2.4. According to exploitation temperatures range

. 3.2.5. According to capability to bear high loads

. 3.3. Grease labeling according to standards

. 3.3.1. Grease consistence (hardness) labeling according to NLGI standard

. 3.3.2. Grease labeling according to ISO standard

. 3.3.3. Grease labeling according to DIN standard

4. Solid (state) lubricants

. 4.1. Solid lubricants division

. 4.1.1. Lamellar solids

. 4.1.2. Polymers

. 4.1.3. Soft metal films

. 4.2. Comparative review of solid lubricants

5. List of various greases available on the market, with usual characteristics

. 5.1. Calcium greases

. 5.1.1. Complex calcium greases

. 5.1.2. Axle grease

. 5.1.3. Marine grease

. 5.2. Lithium greases

. 5.2.1. Lithium complex greases

. 5.2.2. Lithium complex EP greases

. 5.3. Greases with graphite additive

. 5.4. Greases with molybdenum disulfide (MoS2) additive

. 5.5. Greases with Polytetrafluoroethylene (PTFE, “Teflon) additive

. 5.6. Polytetrafluoroethylene (PTFE, “Teflon) greases

. 5.7. Lithium-calcium complex greases

. 5.8. “Silicone” greases (soap greases with silicone oils)

. 5.9. Aluminium and aluminium complex greases

. 5.10. Sodium greases

. 5.11. Barium and barium complex greases

. 5.12. Silica greases – non soap base greases

. 5.13. Bentonite greases – non soap greases

. 5.14. Polyurea greases – non soap greases

. 5.15. Copper “grease”

6. Grease compatibility

7. Recommendation of a bicycle bearings grease

8. Sources and a video

0. Disclaimer

All the information provided in this article, as well as on all of my websites, is to be taken as: “to the best of my knowledge”, or “as far as I know”. I have consulted experts of various fields (and still do), including mechanical engineers, especially when writing on this, rather “can-of-worms” topic, and info provided on my websites does agree with my practical experience, but it still is my opinion – based on my knowledge, education and experience. Different people, including experts, have different experiences and, often, different opinions. I’m sure there are, and will be, people who completely, or partially disagree. Even more often – there is and will be data (experiments, statistics, publications etc.) that might contradict, or seem to contradict my work when read/interpreted by a non expert. All of this is normal and to be expected.

People’s reactions to this particular article seem to range from taking it as a gospel, to taking it as blasphemy. Still – it is no more, and no less than: “what I have learned (through theory and practice) so far”. And, like all the other articles, it gets updated as new knowledge is acquired.

First and only in-page advert:

Thank you for your support and understanding.

1. The loads bicycle bearings take

Bicycle bearings, whether on wheels, cranks, or fork, are usually ball bearings, i.e. they consist of balls, trapped between two races. These bearings are almost never made to be easily re-lubricated from the outside, without disassembling them, so frequent lubrication would take a lot of time.

Since bikes are ridden outside, bearing lubricant needs to keep dirt and water from entering. It should be resistant to being washed off with water, prevent corrosion, while operating temperature ranges from as cold as -20 °C for winter use (though some cyclists are even more extreme), to about 100 °C for bearings of bikes left in hot summer sun, then ridden.

Those bearings need to cope with the load of under 200 kilograms (usually). The load is dynamic, so that impacts can drastically change the volume. However, due to the low weight of a bicycle, only human strength of it’s rider, as well as the fact that a bicycle carries a maximum of two people (specially designed tandems), the forces that occur and bearing loads are relatively small compared to similar in cars, motorcycles, or industrial machinery.

Another important thing is the speed. When a bicycle is ridden around 30 km/h, wheels turn about 250 times per minute (250 rpm). Pedals are rarely turning faster than 100 revolutions per minute, while the steerer bearings rpm is much lower. Also, the distances traveled by bearing balls are relatively small due to the small diameter shaft. When the tyre travels around one meter, hub bearings cover a distance of under 10 centimeters.

So the weight and the speed with which bicycle bearings are loaded are quite modest. While frequent re-lubrication is not practical.

2. Oil as a bearing lubricant

It is quite popular, especially among road bike racers, to pour oil into the bearings (particularly the hubs). The logic is that oil generates much less rolling resistance compared to grease, because it is much “thinner”, more liquid. For the same reason, the oil leaks out easier and is less efficient at keeping dust and water from penetrating the bearing.

It should also be taken into consideration that the design of a bicycle wheel with a hub in the middle makes the lever by which the force is applied to the hub so large that the drag that hubs eventually produce is practically negligible. Especially when comparing the drag of oiled versus the drag produced by properly greased hubs. Even when each second counts, there are lots of other places where the time can be saved (both on the bike itself, as well as with the equipment), while the hubs should be the last thing to experiment on. Of course, everyone chooses by themselves, for themselves, but if hubs are lubricated with oil, it should be noted that this should be repeated every week, or every 500 kilometers ridden – whichever of the of the two comes first.

3. Greases

Before explaining grease types and properties, it needs to be said that there is no such thing as the best grease. There is only optimal choice grease. Optimal as best satisfying all the important criteria. For example: if a grease has best characteristics for lubricating bicycle bearings, but is outrageously expensive, it will not be an optimal choice as long as there is a significantly cheaper grease that has sufficiently good characteristics for the application.

3.1. Attributes that bicycle bearing grease should have

Greases are semi-solid lubricants, used when oils, or liquid lubricants are not appropriate. Either because of higher costs, or for technical reasons. As it was briefly mentioned in previous paragraph, bicycle bearing grease should fulfill the following criteria:

Criterion 1 – Good functioning in a temperature range of -20 to +80 °C. Greases shouldn’t become too hard at the lower, nor become liquid at higher use temperatures. As will be explained, greases that fulfil this criteria need to have a dropping point of at least +100 °C (for hot climates better +120 °C), and the lowest operating temperature (“use temperature” in the remainder of this text) of at least -20 (for cold climate cycling preferably -30 °C).

Criterion 2 – Good corrosion protection and oxidation resistance

Criterion 3 – Good resistance to water wash out and to water and dirt contamination. Per standard ISO 6743-9 at least level E, or better of water resistance. Bicycle bearings are usually not submerged into water, nor is water sprayed on them under pressure. That is why they don’t require water protection levels as some other bearings, e.g. boat trailer wheel bearings.

Criterion 4 – Compatibility with (plastic, or rubber) dusters that some bicycle bearings have.

Criterion 5 – Keeping stable structure and hardness for a longer period of exploitation. Re-lubing bicycle bearings more often than once a year is highly impractical.

Criterion 6 – It should pass 4 ball weld test with weld load over 1000 N.

Criterion 7 – Low price. Out of two greases that both satisfy previously noted criteria, it makes sense to choose the cheaper one. It makes no sense for lubrication, in a medium term, to cost more than replacement of a bearing.

Listed criteria will be used in the remainder of this post note by their numbers. Crit. 1, crit. 2 and so on.

3.2. Grease types division

Most greases (exceptions will be noted and explained) consist of three basic parts:

- Base oil (70 – 90%) – that actually lubricates

- Thickener (3 – 30%) – that keeps the grease hard, holding base oil in suspension and preventing it from leaking out

- Additives (0 – 10%) – that increase beneficial and suppress unwanted attributes of used base oils and thickeners

Even though thickener is what most often gives a grease it’s name (e.g. lithium grease, calcium grease etc), base oil is what does the actual lubrication and usually makes for over 80% of the grease volume. Greases can be divided according to the following criteria:

- 3.2.1. according to base oil type

- 3.2.2. according to thickener type

- 3.2.3. according to intended use area

- 3.2.4. according to exploitation temperatures range

- 3.2.5. according to capability to bear high loads, extreme pressures

Some division criteria are “overlapping”, i.e. different types of base oil can be used with one type of thickener, in order to achieve different grease characteristics. For example, lithium soap based thickener can be used with either mineral, or synthetic base oils to achieve different grease characteristics. In addition to that, in either of the mentioned combinations, another additive can be combined, like molybdenum disulfide for example, in order (in this case) to improve grease’s resistance to extreme pressures, or (extremely) heavy loads.

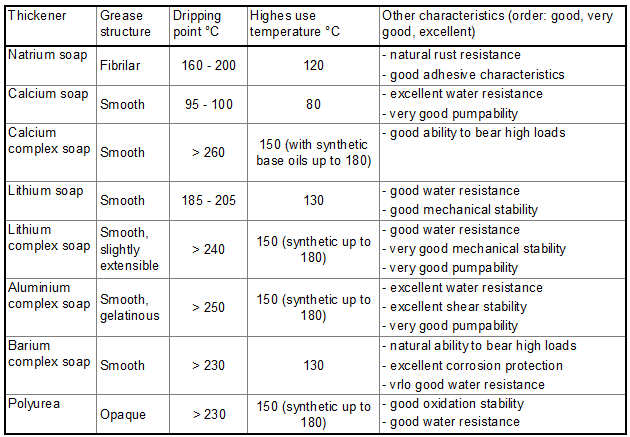

Before grease divisions are given in detail, picture 1 might seem a bit unclear, but it will help for all the data to fall into place. Thickener type is what practically defines a grease type.

Grease types graph

3.2.1. Base oil type division

- Mineral greases. With mineral base oils. Mostly used.

- Synthetic greases. With synthetic base oils. Usually have properties superior to other comparable greases. With a (significantly) higher price.

- Biodegradable greases. Usually made with beet oil. Used where quick biodegradation of lubricant is needed

3.2.2. Thickener type division

- Soap greases. Soaps are usually made by saponification of fatty acids with hydroxides of various metals – aluminium, calcium, sodium, barium.

- Complex (soap) greases. These greases are more of a subgroup of soap greases when dividing according to thickener type. Soaps with long fibres are resistant to mechanical loads, but don’t hold oil in suspension very well, while soaps with short fibres hold oil in suspension well, but don’t take mechanical loads as well. That is why complex greases are made as a combination of (the same metal) soaps that hold oil in suspension well, and soaps that have good resistance to mechanical loads.

- Mixed soap greases. Similar to complex greases, except two different metal hydroxides are used, usually lithium-calcium, or sodium-aluminium. They have superior characteristics to other soap greases (even complex ones), but their price is higher, they are less easily available and are seldom used.

- Non-soap greases. They don’t contain soaps, nor oil that soaps hold in suspension. Non-organic silicone, or bentonite, or organic polyurea.

Table 1 shows grease division and characteristics according to thickener type. Note that maximal use temperature is significantly lower than dropping point temperature (at which grease becomes practically a dripping oil).

Grease characteristics according to thickener type

3.2.3. Intended use area division

- Universal (general purpose) greases

- Special greases with added solid lubricants, such as graphite, or molybenum disulfide (MoS2). Usually used for high load and pressure bearing greases. Special additives, when they are not needed, in addition to increasing the price, can have a negative affect on grease properties for the intended use!

- Greases for roller and plain (slide) bearings.

- Sprocket greases

3.2.4. Exploitation temperature range division

- Low temperature greases – for working temperatures (well) below -20 °C.

- Normal temperature greases – for temperatures from -20 °C to +100 °C.

- High temperature greases – for working temperatures that in a prolonged period of time stay above +100 °C (often even +200, or over +300 °C in some cases).

3.2.5. High load and pressure bearing capability division

- Greases for normal loads and pressures

- Greases that can bear high loads and pressures, i.e. with EP (Extreme Pressure) additives. Just like special additives, greases with EP additives shouldn’t be used when EP characteristics are not required.

3.3. Grease labeling according to standards

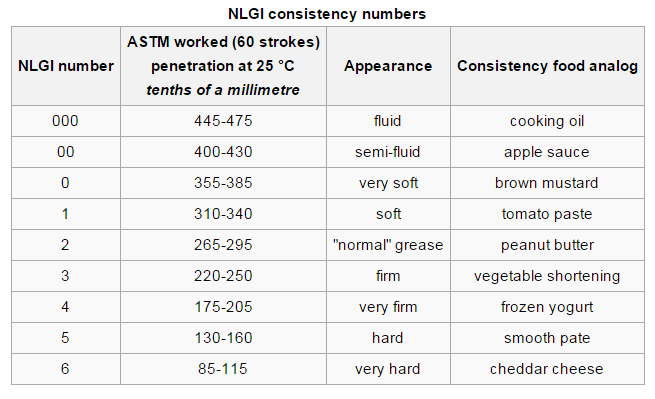

3.3.1. Grease consistence (hardness) labeling according to NLGI standard

Standard for labeling grease consistency is established by American non-profit, independent NLGI (National Lubricating Grease Institute) organization.

Consistency (hardness) is measured with a cone, by methods standardized under ASTM 217 IP 50, or DIN 51804, part 1. Measuring unit represents depth the measuring cone enters the tested grease. Testing procedure is shown in the picture 2 below.

NLGI testing and measuring

In plain English, grease is held at a temperature of 25 °C. It is well meshed (standard prescribes 60 meshing cycles). Then the surface is put in a container, top surface is smoothed over, and a cone shaped plunger is slowly placed from the top to dig into the grease with it’s own weight. Diameter of the hole imprinted by the cone is then measured in tenths of a millimeter. Standard is shown in table 2.

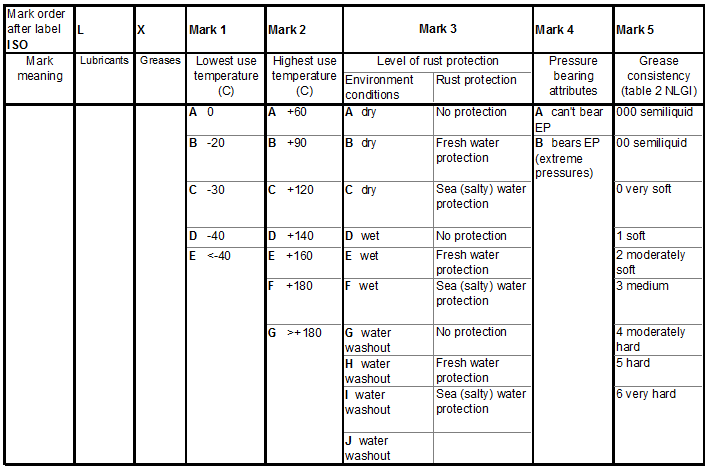

3.3.2. Grease labeling according to ISO standard

According to international standard ISO 6743-9, greases are divided per intended use conditions. Example of an ISO label:

ISO 6743-9: ISO-L-XCCHA 2

Meaning of each letter is given in table 3.

Grease labeling according to ISO standard

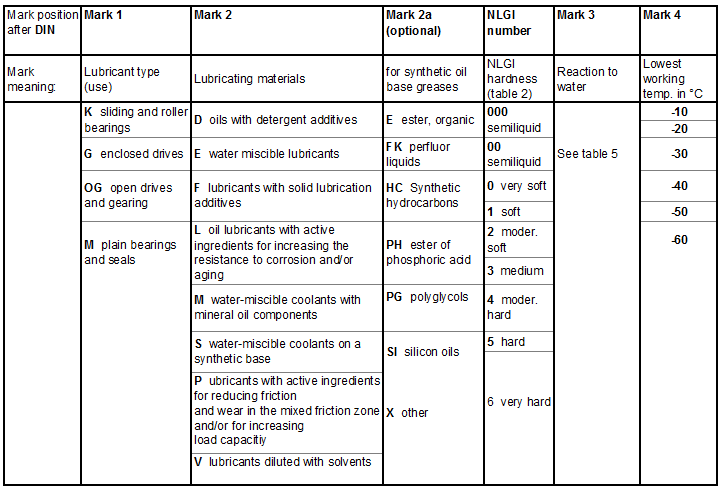

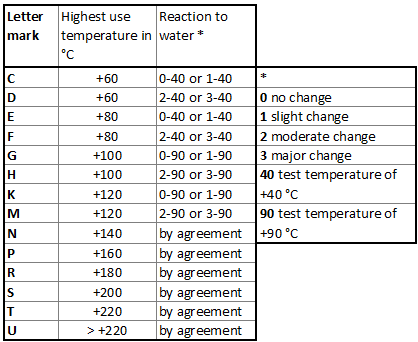

3.3.3. Grease labeling according to DIN standard

German DIN 51 502 standard for labeling greases, unlike ISO, with legendary German precision and efficiency sorts greases according to base oil types, additives etc, so there can be no confusion when choosing the appropriate grease for a given application. 🙂 Example of a DIN label:

DIN 51502: K2 K-30

Meaning of each letter is given in the tables 4 and 5.

Grease labeling according to DIN standard

Reaction to water according to DIN standard

Note:

Mark 2 in table 4 is used only if a grease has some of the ingredients/properties listed in that column – otherwise, the mark is omitted.

See the “Bike greases questions” discussion on the BikeGremlin forum for a bit more details on this.

4. Solid (state) lubricants

Solid lubricant is a material used as a dust, or a thin film layer, to protect adjacent sliding surfaces and reduce wear and friction during their relative movement. In practice, solid lubricants are often suspended in oils, or added to greases (see 3.2.3. special greases).

Solid lubricants are used in extremely high, or low temperatures, extreme pressures, sudden and great variations of loads, hardly accessible parts, parts that can not be regularly re-lubed, corrosive environments, vacuums, or high speed moving parts. Solid lubricants are also practical in conditions where dirt, dust, or sand occur in amounts that could cause problems, because they aren’t as sticky to collect much dirt. They can also fill in gaps between partially worn parts, prolonging the replacement period. Solid lubricants are also used to ensure good running in, instead of wear of recently machined metal surfaces.

4.1. Solid lubricants division

Solid lubricant groups most commonly used are lamellar solids, polymers and soft metal films. In addition to noted, there are some more, better to call them subgroups of solid lubricants, such as multipurpose solid lubricants, combinations of ceramics and solid lubricants, materials made of glass etc. Those lubricants are usually used for extreme and special conditions and temperatures over 1000 °C, to they will not be explained in a post that is about bicycle bearing greases.

4.1.1. Lamellar solids

Graphite. Has low friction coefficient, but use (and maximal use temperature) is limited because in order to minimize friction, it needs to absorb some moisture. It also has a high electrical potential of +25 V, so can cause strong galvanic corrosion of copper and stainless steel alloys in salty water. In practice it is used for temperatures up to 600 °C.

Molybdenum disulfide (MoS2). Like graphite, has low friction coefficient, but doesn’t need to absorb moisture to achieve it (moisture with MoS2 can even somewhat increase friction). Has higher load bearing capabilities than graphite. In environment with oxygen, it can be used for temperatures under 400 °C, while in a non-oxidant environment it is stable up to 1100 °C.

4.1.2. Polymers

Polymers are used as thin lubricating films, as self-lubricating materials for elements manufacturing and as a bonding material for lamellar solids. The most famous polymer solid lubricants are tetrafluoroethylene (TFE), a gas without colour and smell, which with polymerization gives polytetrafluoroethylene (PTFE). PTFE is registered under the (often used) name of Teflon, by DuPont company. One of the most slippery materials on the planet, with a friction coefficient similar to wet ice sliding over wet ice. 🙂

Main advantages of PTFE are low friction coefficient and wide range of working temperatures, from -200 °C to +250 °C. Disadvantages are a higher price and inability to bear high loads.

4.1.3. Soft metal films

Many soft metals, like copper, silver, gold, zinc, lead etc. have low shear resistance and can be used as a lubricant, put in a thin layer over sliding hard surfaces. Soft metal films are useful for tempereatures up to 1000 °C, but are less often used nowadays.

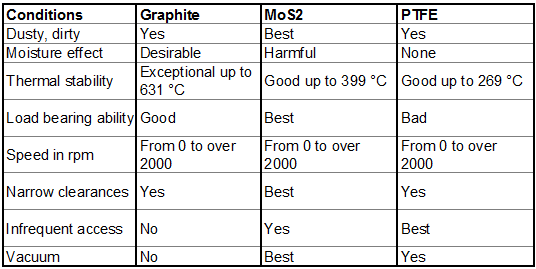

4.2. Comparative review of solid lubricants

Table 6 gives a comparative overview of some commonly used solid lubricants. As can be seen, MoS2 satisfies most criteria and that is why it’s most commonly used, often as an additive to greases.

Comparative review of solid lubricants characteristics

5. List of various greases available on the market, with usual characteristics

Having explained grease type division in paragraph 3, this paragraph explains some produced and available greases, as combinations of thickeners, base oils and (sometimes) additives. As will be seen, thickener type is usually what gives a grease it’s name, with additives (especially in case of solid lubricants) noted as an appendix.

“Usual characteristics” in the heading is written because various manufacturers (and concrete grease models) use various ingredient qualities, so final product characteristics may vary. Concrete characteristics a finished grease possesses is usually written on the label, either in the form of a marketing slogan, or (more reliably) by noting DIN and/or ISO standard that a grease complies with. Characteristics like lowest and highest use temperature, water washout resistance etc.

5.1. Calcium greases

They are widely used and available. Basic calcium greases have low price. Calcium thickener provides the grease with an excellent water resistance. These greases have a relatively narrow working temperature range. I.e. if bicycle is ridden below -20 °C, or it stays in hot summer sun before riding (over +35 °C), then they are not the best choice.

Of important criteria listed in paragraph 3.1. these greases only have problems with fulfilling Crit. 1. (for extreme conditions of bicycle use), while Crit. 3. is probably best satisfied of all the other grease types, except some enormously expensive ones.

5.1.1. Complex calcium greases

Somewhat improved characteristics than ordinary calcium greases. They usually have a higher maximal working temperature (check the label) so they are good for extreme summer heats.

5.1.2. Axle grease

Marketing name for basic, very cheap calcium grease. Slightly lower working temperature range than “ordinary” calcium grease, so not best used for bicycle bearings, but it will do in a pinch.

5.1.3. Marine grease

Grease used for (and marketed as) boat trailer wheel bearing lubrication. Bearings that need to be submerged into sea water when boats are put into the sea. Very good corrosion and water washout resistance. Use temperature range is similar to ordinary calcium greases (if it is complex, then like complex calcium greases). Relatively low price (similar to calcium, or complex calcium greases).

5.2. Lithium greases

Most widely used grease type. Widely available, at a low price. Fulfills all the criteria a bicycle bearing grease should satisfy. Water and rust resistance is not as good as that of calcium greases, but it is more than good enough for bicycle bearing application. Wider use temperature range than similar calcium greases. In case of high quality synthetic base oils, temperature range is even greater, though this raises the price significantly, without much measurable benefits for use with bicycle bearings. Perhaps for extreme (-40 °C cold) uses.

5.2.1. Lithium complex greases

Somewhat wider use temperature range than ordinary lithium greases (completely irrelevant for bicycle bearing lubrication use). Usually have better resistance to corrosion and water washout, similar to that of calcium greases.

5.2.2. Lithium complex EP greases

Same as lithium complex greases with EP (extreme pressure) additives. In fact, lithium complex greases are almost impossible to find manufactured without EP additives. These additives are not needed for bicycle bearing use. With greases, all that is not needed is usually harmful, but in this particular case, no measurable harm comes from the EP additives. They can increase corrosion of coloured metals and silver, but with steel bicycle bearings they are mostly harmless™. Better without them, but no problems with them.

5.3. Greases with graphite additive

Graphite is added to a grease as a solid lubricant, to improve extremely high load bearing characteristics. It is usually combined with calcium, or aluminium greases. Bearing extremely high loads is completely needless attribute for a bicycle bearing grease. You will needlessly pay more, with no measurable practical (or even theoretical) benefits.

5.4. Greases with molybdenum disulfide (MoS2) additive

Similarly to graphite additive greases (5.3.), excellent for high pressures and temperatures, with no negative impact on bicycle bearings. So lithium, or calcium greases with MoS2 won’t be bad for bicycle bearings, just needlessly expensive.

Exception where MoS2 greases are useful can be coaster hubs (hub brakes), where excellent heat resistance can help grease hold it’s own better. However, there are significantly cheaper, almost as good alternatives, like lithium complex greases.

5.5. Greases with Polytetrafluoroethylene (PTFE, “Teflon”) additive

PTFE is usually added to lithium grease. These greases differ from “teflon” greases, where PTFE is used as a thickener (with a synthetic base oil usually), not as an additive. PTFE improves grease performance with high speeds (measured in thousands of revolutions per minute). With greases for lubing bicycle bearings, PTFE as an additive needlessly increases grease price, but doesn’t harm (nor does it benefit) grease’s performance (not even in theory).

5.6. Polytetrafluoroethylene (PTFE, “Teflon”) greases

Greases where PTFE isn’t an additive, but a soap (or combination of PFTE/PFPE soaps), that keeps base oil in suspension. Harder to find, more expensive, less compatible to mixing with other commonly used greases (see paragraph 6.). Apart from that, characteristics are good for lubricating bicycle bearings.

5.7. Lithium-calcium complex greases

Combination of complex lithium and calcium soaps thickeners. With quality base oils these greases can be made to be superior to complex (even more so compared to ordinary) whether lithium, or calcium greases. They are less easily available and higher priced though – with no measurable benefits for use in bicycle bearings compared to quality lithium soap based greases.

5.8. “Silicone” greases (soap greases with silicone oils)

Silicone oils suspended in a soap of lithium, calcium, PTFE, fumed silica etc. Lithium soap based silicone greases have excellent properties for lubricating bicycle bearings, but are outrageously expensive. Because there are greases that cost a lot less, while being good enough, and because it makes no sense for lubrication after a few seasons to cost more than a new bearing, silicone greases are not an optimal choice.

5.9. Aluminium and aluminium complex greases

Not to be confused with aluminium anti seize pastes. Similar to lithium greases, with better water resistance (similar to calcium greases), but with a significantly higher price.

5.10. Sodium greases

Poor resistance to corrosion and water washout, so not good for lubricating bicycle bearings.

5.11. Barium and barium complex greases

Good water resistance, high dropping point, but limited low temperature use (slightly worse even than calcium greases). Very high price. Barium and many of it’s compounds are toxic!

5.12. Silica greases – non soap base greases

Greases without a soap. Thickener is amorphous fumed silica. Silica greases posses good oxidation resistance and thermal stability, good resistance to water and acid washout, while their hardness doesn’t change with the change of temperature. Because of a high production price and limited high load bearing capacity, silica greases are limited to high temperature grease use.

5.13. Bentonite greases – non soap greases

As a thickener, modified clay – bentonite – powder is used. Greases for high working temperatures. High price and incompatibility with most other grease types make this grease not the best choice for lubricating bicycle bearings.

5.14. Polyurea greases – non soap greases

After describing non soap greases with a non-organic thickener, it is time for an organic thickener one – polyurea. These are usually picked for their good high temperature characteristics (dropping point is over 260 °C). These greases have thixotropic properties (i.e. they soften when lubricated parts are moved, then harden back to original consistency when stationary).

These are high quality greases with excellent lubricating, water resistance, extreme pressure bearing and oxidation resistance properties.

The main flaw when using these greases for bicycle bearing lubrication is it’s relatively higher price. Also, low compatibility with other greases can be a potential problem – in case of adding grease without previous complete washout of the existing grease.

5.15. Copper “grease”

Quotation marks because it actually is an anti-seize (mounting paste) compound. This “grease” is used for high temperatures – lubing sliders of disc brakes, where lots of heat is generated when braking. It is also perfect for preventing parts from seizing together – perfect for lubing seat post, all the bolts and nuts, bottom bracket threads – it will prevent metal from binding together, but not be too slippery to ask for a lot more torque when screwing in. As an anti seize it is one of the most effective products. However, for bearings themselves, it is too hard, to thick.

6. Grease compatibility

Now that grease types and solid lubricant (additives) types have been explained, it is clear that there are numerous possible combinations. For the purpose of re-lubing an already lubed bearing, if completely washing out old grease is not possible/practical, it is important to know which greases (with which additives) are compatible (i.e. can be mixed) with which greases.

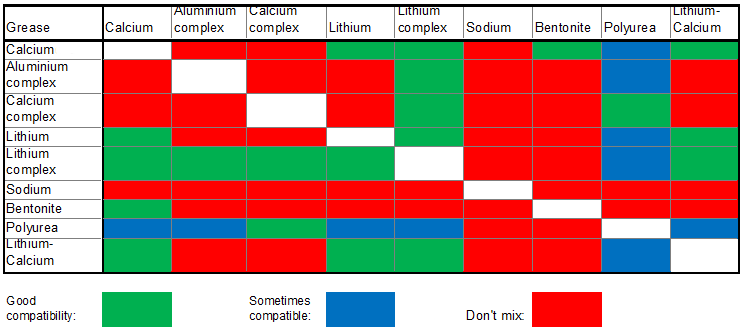

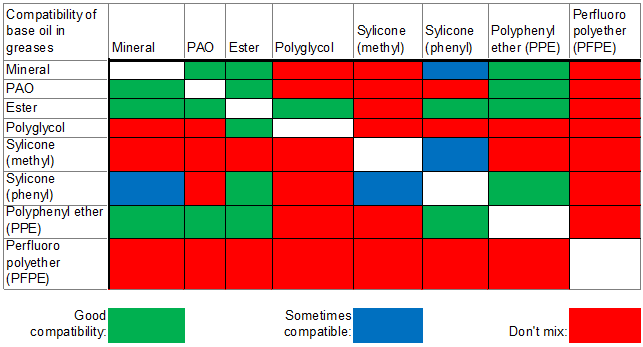

As a general guide, one can use the following: greases with the same types of thickeners and similar base oils are usually compatible (e.g. lithium grease with another lithium, or even lithium complex grease). Table 7 shows grease compatibilities based on thickener compatibility, while table 8 shows base oil compatibility. Both compatibilities should match in order to safely mix the two greases.

Compatibility of various types of greases

Compatibility of grease base oils

7. Recommendation of a bicycle bearings grease

Recommendations in this paragraph are author’s personal opinion based on knowledge and experience.

First some general guides will be given, then with more specific grease types.

- Optimal hardness for a bicycle bearing grease is NLGI 2, whichever grease type is chosen.

- General recommendation would be an ordinary lithium (soap based) grease. Available, cheap, with characteristics that satisfy all the criteria for this use. It hardly makes sense using anything else. Even those satisfying ISO water resistance standard with H level are not too expensive.

- If riding environment has lots of rains and/or sea water, good choice is calcium (soap based) grease (or “marine” grease). Available, cheap, with good water resistance. The only situations where this grease is not a very good choice are extreme heats (bike left for hours in over +35 °C summer sun), or riding in very low temperatures (below -15 °C).

- For a wide range of working temperatures (for -25 °C to hottest Africa heat), with very good water resistance attributes, but not too expensive – lithium complex grease with ISO water resistance level I. With, or without EP additives (doesn’t really matter). Still, this grease costs about double the price of ordinary lithium, or calcium based greases.

- For deep freezing temperatures, below -30 °C: choose either calcium, lithium, or calcium-lithium (mixed) grease, whether plain, or complex, with noted lowest working temperature of at least -40 °C (preferably -50°C).

- For coaster brake hubs (hub brakes) – good choice are greases that can withstand high temperatures (generated when braking). Lithium-complex soap based greases, or (if not sparing money, or they are already at hand) – lithium complex with molybdenum disulfide (MoS2).

Special types of “bicycle grease”, sold in many bike shops, or on-line rarely have a label noting standards it satisfies, often even don’t have fully and clearly listed ingredients. It’s up to the buyer to trust the manufacturer that it is the best grease for a bicycle. I’m yet to do lab testing of “special bicycle greases”, but when I do – they’d still have to be really, really exceptional to justify the price difference from a regular car-store sold lithium soap based grease, that fully satisfies all the criteria.

Author’s recommendation of greases from Amazon.com on-line shop (clicking on an image below opens Amazon affiliate link for on-line shopping). As an Amazon Associate I earn from qualifying purchases.

Note: listed greases are the ones I could find that are of good quality and with a world-wide distribution. Feel free to look for cheaper, locally available options. My 1st choice is local, Serbian made FAM FORPLEX 2 grease.

Update, December 2023:

Grease I’ve been using mostly over the past year is Motorex 2000 grease (also sold as “Motorex Bike grease”). Why? It is “officially” (by the manufacturer’s specifications) neutral towards plastic and many kinds of rubber (not to be used on DOT for brake rubber seals though). And it has a nice colour, but is mostly transparent, so I can easily see where and how much I’ve applied. 🙂 It is needlessly expensive for what I’m getting, but since I often work on other people’s bikes, and bikes are getting more and more plastic and carbon parts, I want to minimize any liability. This grease is calcium based.

8. Sources

- https://motornaulja.blogspot.rs/

- http://www.maziva.org/izbor-maziva/mazive-masti/

- http://www.axelch.com/wordpress/wp-content/uploads/2014/12/WhitePaper-16.pdf

- https://bobistheoilguy.com/functions-of-grease/

- Rolling Bearing Analysis – Tedric A. Harris (Amazon affiliate link, I’ve used a borrowed, older, 4th edition)

Author:

Relja Novović – BikeGremlin

Coauthor:

Stevan Dimitrijević (dr of metallurgical engineering)

Author of the greatest site (blog) in serbo-croatian language about motor oils and lubricants:

https://motornaulja.blogspot.rs/

Related post – Types and designs of bicycle bearings:

If you have any questions (or additions and corrections), please use the BikeGremlin forum – this is the forum topic related to this article:

https://www.bikegremlin.net/threads/bike-greases-questions.64/

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/bicycle-bearing-greases-explained-article-comments.105/

More food for thought here:

https://forum.cyclinguk.org/viewtopic.php?f=1&t=121287

The guy seems to have very thorough knowledge about mechanics and chemistry, so I’d rely on him. What he says, contrary to your views, is that solid lubricants, like graphite or MoS2, are actually very beneficial for a bicycle bearing.

I don’t believe I expressed a view on solid lubricants, and the excellent blog post you linked clearly shows that the Stribeck Curve dictates that for a given load, the slower the bearing moves the higher the viscosity (thicker, more adhesive & cohesive) grease is called for.

My ’06 Specialized Roubaix came with press-in cups, loose balls, and a split-crown race – pretty much the worst piece of crap bearing possible, and despite NEVER riding in the rain, I could have grown potatoes in the lower headset after 3yrs. Rusted, pitted and absolutely filthy. I rode it all yr around too, so it didn’t get FUBAR sitting around in my bedroom, it got FUBAR from dust and the occasional puddle splash from rouge irrigation systems.

With 20-20 hindsight, I think Marine grease would have been excellent for that application, and annual servicing as well. Like many others, I replaced those bearings with a Cane Creek 110 sealed bearing system, BUT, those have much less engagement area, 8-10mm vs ~30mm with the original press-in. As you might expect, and Chris King and others have been very vocal about, in time the small engagement area results in the slow, steady peening of the aluminum bearing face inside the headset. My RX for AmsOil’s Off-Road grease is for stopping the creaking that has resulted by resisting Pound-Out so it continues to take up the tiny space peening has created. Of interest to you, that grease has Moly in it, although Moly isn’t really meant as a lube, it’s meant to fill in the pores of hot metal to create a less toothy surface so the oil film can work better at any speed and load.

As for heat, as the linked blog discussion indicates, while overall heat is usually not an issue, momentary micro heating, resulting in welding occurs regularly, and Moly might help here too, as would a high 4-Ball test due to a superior synthetic oil or Teflon film.

As for disk brakes transferring heat to hubs, it’s been a big problem in the past, and given the rather solid surface on road disks between the caliper engagement area and the hub, probably still is on road bikes. This seems like a perfect test for https://www.bicyclerollingresistance.com to conduct. I idea is to put a disk braked wheel on their drum and brake while using an IR sensor to record temps with the idea to continue until hub temps become a problem – or not.

Since professional European tour riders have gotten branded from disk brakes on road courses there’s plenty of heat that needs dissipation, and based on 3 generations of designs to address that problem by brake mfgs, it seems likely it’s a problem. Beyond that, and they may have their own data set, Santana tandems stopped putting disk brakes on their bikes because there were none with rotors large enough to handle the heat. I will contact them and see if they would like to add to this discussion.

My favorite grease is still pure 100% PTFE – Teflon grease, but it’s too expensive to fill large cavities with, so I use FinishLine’s 100% on the balls (or needles) and then fill the space left with their Teflon-fortified grease, based on the fairly safe assumption that grease with Teflon in it will be compatible with still more Teflon if they mix.

BTW, the Stribeck Curve doesn’t say where oil film failure will occur for any particular grease, just that viscosity, velocity and load all affect it. In particular, that for a given load, as velocity slows, viscosity should rise to keep the equation in balance. Teflon’s film is over 2 orders of magnitude tougher than some oils, like WD-40, but that said, oil film integrity isn’t the only consideration, though, is it?

For example, if I were routinely riding a loose-ball mtb in wet conditions I’d probably select a Marine grease because it’s made to keep water out, not wash out, resist corrosion, and maintain a good oil film even in the presence of water. In part it does this by using solids like Moly. Ditto for the pedals and headset, but probably not the hubs, but wouldn’t it be nice to know? I mean, WTF, for the price we pay for bicycle grease, and the cost of what it protects, why the hell don’t we know what’s in the grease we buy? There should be standardized “nutrition labeling” for grease, for some of the very reasons we’ve been discussing. NLGI standards are a joke, and everybody in the industry knows it and devises their own tests to prove performance, as Gareth Fish’s White Paper makes clear.

http://coastlubricants.com/wp-content/uploads/2017/01/Lubrizol-WhitePaper-2016.pdf

I have been looking for information about lithium complex grease vs. calcium complex grease. I will use the grease for multi purposes. Bicycle, car and motorcycle. Your article was very helpful. I have chosen til lithium complex grease.

Best regards

Martin Holm

Glad it was helpful. 🙂

I also go with Lithium complex (for both the push, and the motor-bikes 🙂 ), but it’s fair mentioning:

regular cleaning and re-lubricating (i.e. regular maintenance) is a lot more important than the grease type, or even quality

(as long as it’s not something completely inappropriate for the application, and/or of a surprisingly low quality).

Still, I sleep better when using the best matching grease type, of a high quality, and I would say that lithium complex is probably the “most universal” and probably the best choice for your intended use (multi-purpose grease).

Relja

Hi Relja,

I would like to hear your thoughts on what you recommend for DT-Swiss’s star ratchet system in their freehub body. They recommend their own product “DT-Swiss special grease” which is actually TP-42 Molykote + 5% Mineral oil. However this is quite expensive and not that readily available near me (East Coast US). Would you recommend any other grease that is readily available for this specific application ( teeth of the freewheel body). You can see their maintenance recommendations here as well: https://www.dtswiss.com/pmt/00/00/00/00/00/00/00/10/00/00/04/19/3/MAN_HXD10000004193S_XXX_EN_001.pdf

Also, they have a general grease that they recommend for the hub. Would the ones you recommended (Mobil XHP 222) be fine for this? Thank you in advance!

Hi John,

What Long_Rider replied does make a lot of sense. Gear oil has proven to be a good option for Shimano freehubs.

Having said that, very soft grease should also do the job. Semi-liquid, like NLGI 0, or even NLGI 00. Shimano gear-hub grease is premium price soft grease suitable for such fine mechanisms (I usually use that, because I have it at hand, for its original intended purpose on other people’s hubs).

Mobil XHP 222, if used sparingly (with any excess wiped off) could do the job, but I’d use a soft version (NLGI 0), i.e. XHP 220.

I could be wrong but I expect hard grease to increase the risk of the mechanism sticking and not working perfectly (with Shimano freehubs that’s definitely the case, haven’t risked it with DT-swiss).

Relja

John,

I hope you don’t mind me chiming in here. I found your question intriguing.

Chris King uses the same star ratchet system, which is a ratchet implemented by two face ratchets pushed together under only slight pressure. It has the characteristic “Angry Bees” sound. For such an application you do NOT want a sticky grease, IE: one with high cohesion, and probably not much adhesion either, as a thick layer of grease would tend to hold the ratchet plates apart, as is warned of in DT’s Maintenance Document.

Given DT generally has excellent seals, I would opt for no grease at all, but a thick-ish gear oil designed for high gear loading. It will have excellent wear resistance at the ends of the teeth where loads are the highest, & where DT directs you to check for wear. This oil is engineered for the very high gear loading of hypoid gears AND has an additive to protect and extend the life of seals. More importantly, it is very thermally stable, so should NOT be adversely affected by cold weather, which would thicken a grease to a point where ratchet engagement failure is almost certain. It will also not degrade in heat, even when riding hard in 125F heat in Phoenix.

I would RX a special treatment of the ratchet faces though. Clean them absolutely bone dry by using carburetor cleaner and 99% rubbing alcohol or boiling them in distilled water and Simple Green. Then put them in a metal container and heat them to ~ 350F in the gear oil for 15mins. This will bond the gear oil to the metal very strongly and provide a base of lubrication that is unparalleled. PLEASE do make sure the oil does not affect the tempering of the metal, which I assume is either stainless, maraging steel, CroMo or tool steel, so probably not a problem until well over 500F, but 350F should do the trick. I have used this technique extensively to restore steel parts on vintage bikes and it works wonders.

Cheers!

https://www.mobil.com/en/lubricants/for-businesses/heavy-duty-lubricants/products/mobil-delvac-1-gear-oil-75w-90/