This post explains what bicycle chainline is. Why is it important? How is it measured? How to set a “correct” chainline?

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

Table Of Contents (T.O.C.):

- What is a bicycle chainline?

- Why is bicycle chainline important?

- How to measure bicycle chainline

3.1. Measuring front chainline

3.2. Measuring rear chainline

…..3.2.1. Offset frame rear chainline - How to set a correct chainline?

4.1. Front chainline adjustment

…..4.1.1 Chainline for 1x drivetrains

4.2. Rear chainline adjustment - Deliberate imperfections

- Apendix – axle lengths for BBs with axles

6.1. Square taper axle length video - VIDEO about the chainline (shown and explained)

- Chainline table

8.1. Why is 1x chainline wider than 2x or 3x chainlines?

TL/DR

For your bike to run well (with good shifting, less chain noise, and longer lasting drivetrain), it is important for your front chainring(s) to be in line with your rear chainring(s).

This article explains how to measure if they are in line, and how to fix any imperfections (and improvise if needed).

1. What is a bicycle chainline?

Definition is: distance between the middle of chainring(s set/s) and the longitudal axis of the bicycle. It is explained in plain English in this post. 🙂

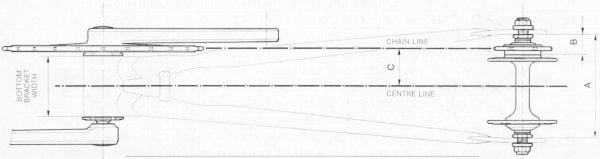

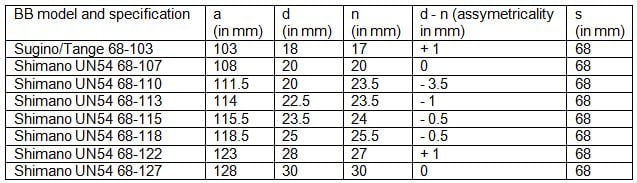

Middle of the front chainring and middle of the rear sprocket should be at the same distance from the axis that goes along the middle of the bicycle frame from the front to the back. That means the chain will run completely straight from the front to the rear. For bicycles with more speeds, definition is the same, only measurement is taken as middle of the sets of chainrings and sprockets. Picture explains it better:

Front and rear sprocket are at the same distance from the longitudinal axis of the bicycle. The chain runs perfectly straight, parallel to the longitudinal axis of the bicycle.

Picture 1

When measuring, the middle of the rear sprocket set is taken as a reference, aligned with the middle of the front chainring set.

Picture 2

Help BikeGremlin

stay online & independent

This website is educational, free, objective, and not commercial

(sponsors don’t enjoy paying if you mention all the product downsides that you notice 🙂 ).

How much does a WordPress website cost?

If you find this site to be good and helpful,

and if $5 per month is what you can afford to set aside,

please consider supporting my work with a Patreon donation:

2. Why is bicycle chainline important?

For single speed bicycles (one chainring at the front and at the back) the answer is more obvious: the straighter the chain, the longer it will take for it to wear out, the less mechanical losses it creates when pedaling and the harder it will drop off the chainrings.

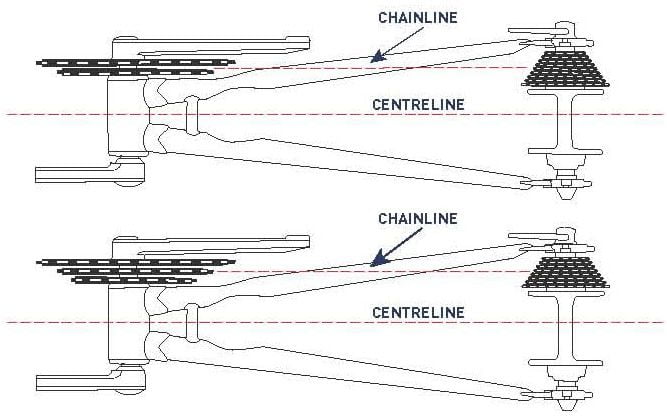

For multi speed bicycles (more sprockets), the answer is a bit more complicated. If the middle of front chainrings is not aligned with the middle of the rear sprocket set, then in some gear combinations, the chain will be too crossed. Picture below explains it better:

Picture 3

Upper half of the picture number 3: middle of the sprocket set is aligned with the middle of the front chainring. That way, in either gear combination, the chain is not at a great angle (green lines).

Lower half: front chainring is too far out compared to the middle of the sprocket set. That means that in top gear (blue line), the chain is almost straight. However, in lowest gear (red line), the chain runs at a sharp angle – bringing more wear and tear to both the chain and the sprockets, more noise and less mechanical efficiency of the whole system.

For double chainring set – the middle between the two front chainrings should be aligned with the middle of the sprocket set. For triples – middle chainring is aligned with the middle of the sprocket set. This is shown in the picture 2.

3. How to measure bicycle chainline

3.1. Measuring front chainline

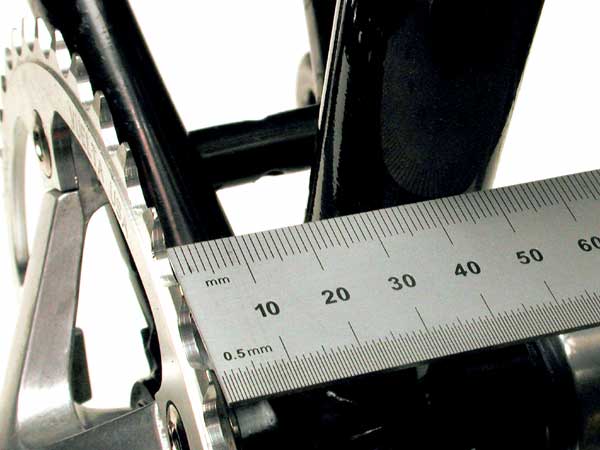

It can be measured simply with a ruler:

Picture 4

Technically more precise measurement is taken this way:

- measure the diameter of the seat post and the width of the front chainring (set) with vernier calipers. “Set” means the total width of the two, or three chainrings if the crankset is a double, or a triple one.

- measuring distance from the seatpost to the end of the largest chainring.

- add half of the seatpost width to the measured distance, and then deduct half of the chainring (set) width. That’s the front chainline.

44 / 2

+ 29

– (9.8 / 2)

Picture 5

For the example in picture 5, the chainline would be:

44 / 2 + 29 – (9.8 /2) =

= 22 + 29 – 4.9 = 46.1 mm

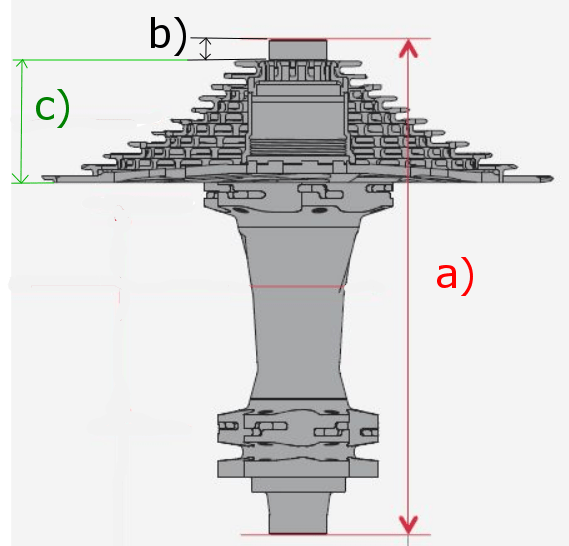

3.2. Measuring rear chainline

Measure the width of the rear hub. OLD (over locknut distance).

Picture 6

The whole axle is not measured, just the inner locknuts that hold the hub bearings in place. For solid axles – outer nuts that hold the wheel in place are disregarded. Only the part of the hub that sits against the inner part of the rear dropouts is measured.

Most modern rear MTB hubs are 135 mm wide (OLD), most road ones 130 mm, while older road hubs are 126 mm. Ancient road and newer single speed hubs are usually 110 to 120 mm wide.

With help of a picture, the procedure is more easily explained:

Picture 7

- First measure a), like explained in the text above

- Then measure b) – from the hub locknut, to the begining of the smallest sprocket. Measure to the face of the sprocket itself, not to the locknut holding the sprockets in place.

- Finally measure c) – from the beginning of the smallest, to the end of the largest sprocket

Rear chainline = (a / 2 ) – ( (c / 2) + b)

For example: if a = 135 mm. b=4 mm. c = 35.4

Chainline = (135 / 2) – ( (35.4 / 2) + 4)

= 67.5 – ( 17.7 + 4)

= 67.5 – 21.7

= 45.8 mm

3.2.1. Measuring offset frame rear chainline

For an offset frame, simply add the frame’s offset to the rear chainline you measured and calculated using the procedure explained in the previous section (section 3.2).

Offset frame manufacturers usually provide information about how much the frame is offset (usually expressed in millimetres). It is very difficult to manually measure a frame’s offset accurately.

4. How to set a correct chainline?

By setting a correct chainline it is meant to set front and rear sprockets so that their middles are in line, like shown in pictures 1 and 2. Literally: front chainline (measurement explained in paragraph 3.1.) and rear chainline (3.2.) should be the same.

When doing that, rear sprockets are usually taken as a fixed position, with front chainring position set to match them. That case is first explained under 4.1.

4.1. Front chainline adjustment

- For single chainring crankset, where chainring is bolted to the spider holding it, the chainring can be moved outwards with adding spacers between the chainring and the spider, then bolting it. To move the chainring inwards, it can be mounted on the inner side of the spider, with fine adjustment made using spacers, as shown in picture 8:

Picture 8

- With triple cranksets, smallest, or largest chainring can be removed, or front derailleur set so it never moves onto one of them, effectively altering the chainline according to needs.

- A spacer can be added between the right bottom bracket cup and the frame, in order to move chainrings outward.

- Longer, or shorter axle (spindle) can be used with square taper and Octalink bottom brackets to move the chainrings outward, or inward. When using shorter axle, make sure that crank arms aren’t too close to the frame so they don’t hit the rear chainstay when turning.

- Replacing crankset for one with more outward, or inward placed chainrings.

It is important to bear in mind the type of chainrings (crankset) used. This goes especially for square taper cranks. On an axle of the same width, some will stick further outwards, while others may be positioned more inwards, towards the frame. This plays an important role when choosing a correct BB axle length. Some crankset manufacturers publish required axle lengths for desired chainlines, while with others it’s more trial and error.

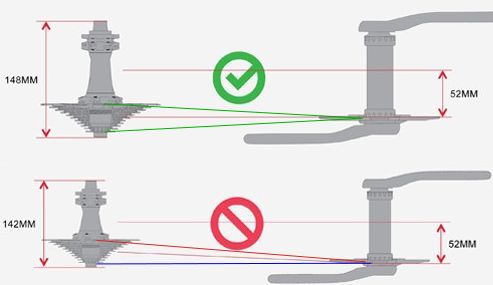

4.1.1. Chainline for 1x drivetrains

With 1x drivetrains, it is optimal to have the front chainline be about 2 mm larger (more outwards) compared to the rear chainline.

This helps avoid chain scratching against the adjacent larger sprocket when it’s past the middle of the cassette – on the smaller sprockets (1x cranks are often paired with cassettes that have huge sprockets and large differences in adjacent sprocket size).

4.2. Rear chainline adjustment

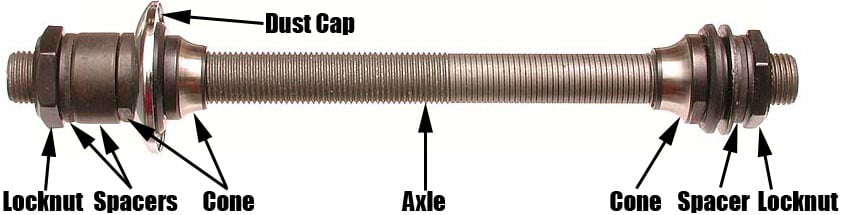

Adjusting the rear chainline is done by rearranging the rear axle spacers.

- Spacers from the left side are placed on the right, to make the sprockets move inward.

- Spacers from the right are moved to the left side to make the sprockets move outward.

It is important to note that this affects:

- Room left for rear sprockets – they might start rubbing the frame if too many spacers are removed from the right side.

- Disc brake alignment – make sure disc brake calipers can be moved laterally enough to match the sprocket rearrangement. If a spacer is added to the left side, disc brake calipers must be moved inwards. If a spacer is removed from the left side, calipers must be moved outwards.

- Rim alignment – rim will no longer sit in the middle of the frame, and must be re-dished. If a spacer is added to the left side, left hand side spokes must be tensioned to move the rim back into the middle. If a spacer is added to the right side, right hand side spokes must be tensioned to center the rim.

There must be one cone and one locknut at each side, while spacers can be moved.

Picture 9

It can be also combined by discarding a wide spacer and replacing it with a narrower one from some old axle, then placing a third, narrower spacer on the opposite side to keep the total used spacer width the same.

Setting correct chainline using the rear hub is a complicated task that is not recommended, unless it’s not possible to get a satisfactory chainline by adjusting the front chainrings. It’s often better to leave a less than perfect chainline, than to mess with the rear hub spacers.

5. Deliberate imperfections

I do most of my riding from the largest front chainring. That’s why I like to have my chainrings more to the inward, than it is perfect. That way, the chain is a bit more crossed when using smallest chainring, but where I do most of my riding, on the big chainring, the chain is straighter than it would be if I had set the correct chainline.

The rule of thumb and a safe bet is to set the chainline correct, but if one is certain what they are doing, they can play with imperfect chainlines. Of course, diverting from perfect chainline has its drawbacks and consequences, like shown in picture 10:

Picture 10

Important note: when experimenting with imperfect front chainlines, for bicycles with front derailleurs (FDs), it is important to make sure the FD can reach all the chainrings. If they are moved too much outwards, FD might not reach far out enough to shift to the largest chainring, and vice-versa – if moving chainrings too much inward, FD might not be able to move in enough to shift to the smallest chainring.

Also, make sure that right and left-hand side crank distance from the frame is not greatly different, since that could affect ride comfort (having one foot moved substantially more towards the outside, compared to the other foot).

6. Apendix – axle lengths for BBs with axles

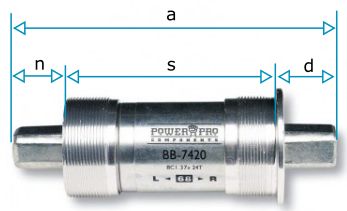

Axle measurements for BBs with axle (square taper and Octalink are the most widely used ones) are noted in picture 11:

d) Drive side (chainrings side) length

s) Width inside the frame’s BB shell

n) Non-drive (left) side length

Picture 11

Measurement d) is always taken from the inside of the flange that aligns with the outer side of the frame’s BB shell. The drive side is always screwed all the way in, until the flange stops at the BB shell wall.

Table 1 shows measurements of some existing cartridge BB models:

Some typical measurements.

As a guide to what to measure and look for.

a) Axle length

d) Drive side (chainrings side) length

s) Width inside the frame’s BB shell

n) Non-drive (left) side length

Table 1

For Shimano square taper cartridge bottom brackets combined with Shimano cranks, optimal axle lengths are usually (not always, it’s best to mount and measure):

- 110 mm for single chainring cranks (single-speed and 1x).

For example, a 110 axle will result in a 46 mm front chainline; 113 will give you 48 mm; and 117 will give a 50 mm front chainline. - 110 to 113 mm for double chainring cranks.

- 122.5 (122 ~ 123) mm for MTB triple cranks.

Sometimes, depending on the rear chainline, a 117 mm axle length can fit better.

Shimano often notes on a paper inside the package of their (square taper and Octalink) cranks which BB model (and axle length) gives which chainline with that particular crank. Without this, it’s often a trial and error, with various axle lengths.

6.1. Square taper axle length video

My video explaining how to find an optimal square taper BB axle length:

7. VIDEO about the chainline (shown and explained)

A video where I’ve explained the chainline and shown how to measure the front and the rear chainline:

8. Chainline table

A BikeGremlin forum chainline question inspired me to finally make this chainline table. The table (well, list, technically) should help you get the ballpark values when buying new components or planning bike builds.

- Single speed & fixie: 40.5 (old bikes with 110 mm dropouts) to 42 mm (newer SS bikes with 120 mm rear dropout widht)

- Road double: 43.5 mm

- Road triple: 45 mm

- MTB triple: 47.5 to 50 mm

- 1x for 135 mm QR or 142 mm thru-axle rear dropouts, and BOOST 148 mm frames: 52 mm

- 1x for BOOST 148 mm rear dropout width, for more wide tyre clearance: 55 mm

- 1x Super-BOOST 157 mm frames: 56.5 mm

- Tandem bicycles: 60 mm

- Fatbikes with 170 mm rear dropout spacing: 66 mm

- Fatbikes with 190 mm rear dropout spacing (and 4.8″ wide tyres): 76 mm

- Rohloff geared hubs chainline (link to the official website).

8.1. Why is 1x chainline wider than 2x or 3x chainlines?

The front chainline is how far out the mid-section of all the chainrings is from the bicycle’s centre-line. I’ll re-post the picture 2:

When measuring, the middle of the rear sprocket set is taken as a reference, aligned with the middle of the front chainring set.

Picture 2 – again 🙂

With double and triple cranks, chainrings are spaced at about 5 mm from each other (perhaps about 6 mm on 7 and 8 speed cranks). So:

- With triple cranks, when the middle chainring is at 50 mm, the outer (largest) as at 55 mm, and the inner (smallest) at 45 mm.

- With double cranks, when the chainline is 52 mm (that is the mid section between the two chainrings on a double), the inner chainring is about 2.5 mm inward at 49.5 mm, and the outer chainring is 2.5 mm outward, at 54.5 mm.

Now, for the 1x cranks, there is no chainline adjustment via shifting (shifting to the smaller front chainring when using the inner, larger cassette sprockets, and shifting to the larger chainring when using the outer, smaller cassette sprockets). So, 1x is a compromise, and you get a pretty awkward (bad) chain angle when using either largest two or smallest two cassette sprockets.

Another peculiarity is that 1x systems are usually paired with pretty large cassettes (40+ teeth on the largest sprocket) to provide both low and high enough gearing with only one front chainring. This results in chain rubbing against the largest rear sprocket when on the second largest rear sprocket if the front chainring doesn’t sit far enough out.

That is why 1x drivetrains usually use a bit larger (wider) chainline for their only chainring (~ 52 mm), instead of aiming for the 50 mm.

Is it bad for the chain and chainrings when climbing on the largest rear sprocket and putting out a lot of torque? Yes it is. Increased component wear (and cost of the huge cassettes) is a downside of 1x drivetrains (1x drivetrain pros and cons). That is why people invented front derailleurs and multiple front chainrings over half a century ago.

Having said that, modern chains are quite flexible sideways, so they can take that without breaking. Just increased cost and wear. That’s good for sales. Cyclists, on the other hand, are happy for not having to figure out how to shift gears with multiple front chainrings, while the extra cost is not that problematic for many.

The cynic in me says the whole modern 1x (as 1x did exist decades ago before it got replaced with doubles and triples) was started by the marketing team of the company that just couldn’t make a decent front derailleur, and was desperate to gain an edge over Shimano, but nonetheless, 1x took off, people like it, it is modern, trendy, and is here to stay (until companies “re-invent” the good old triple when they go looking for something new, and not compatible with the existing stuff 🙂 ).

Related post – Approach to bicycle servicing:

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/bicycle-chainline-article-comments.125/

Check the clearance between each chainring and it’s nearest point to the frame in mm. Take the crank off and measure from the end of the spindle to the shoulder of the BB housing on the frame. How much shorter does it need to be? (Ideally 13mm). Is every chainring more than 13 mm from the frame? Take a measuring implement to the shop and buy the cartridge BB that is right for you. Tell me if that’s not clear.

I’ve messured the rear chainline and find 54mm. In the Shimano A070 crank’s manual recomend the front chain line in 43.5. Messuring the front chainline as is now, I’ve finded 56.5mm with a 125mm BB. So my conclusion is that to have the same chainline rear and front I need less 2*(56.5-54) in BB lenth. Só 125-5 = 120mm BB. Is that correct?

What matters is to have the same rear and front chain line if I undestanded well.

Thank you a lot !!

Hi There,

I have 142mm at the back (drop put – drop put) so ideal chainline should be 49mm at the front..

Here is the problem, I have 73mm frame, if I follow Shimano’s instruction (73mm frame = one spacer at the Drive Side) I will have 51,5mm at the front.

So that means that I should leave DS without spacer..

My question is: What should I do with the NDS and should I leave spacer out or in on the DS?

Thank You!

Hi Harun,

Shimano Hollowtech II BB’s I suppose?

If yes – they come with a plastic “sleeve” that is intended to protect the axle. If there are not enough spacers, that sleeve can get compressed by the cups a bit too much, and crack.

Axle hangs in mid-air inside the frame – not touching anything. A light coating of grease should be able to protect it from rust and I don’t think that sleeve is really necessary. So I wouldn’t expect any problems even if it cracks.

Having said that, depending on which gear combos you use most of the time, being 1.5 mm more outwards compared to a perfect chainline is not too bad, it can even be beneficial. If you ride a lot in the middle ring on a triple crank, for example. While, if you have a double, or a triple and use the big ring a lot, it’s better to have the front chainline a bit smaller than the rear chainline, so the chain doesn’t get as much “crossed” when using the middle of the cassette from the big ring. For that kind of use, I’d ditch the drive-side spacer (and if you hear any cracks while tightening the cusps – that was the sleeve 🙂 ).

As for the NDS – I’d see how centred the cranks are when I mount it all, without tightening anything too much, making it a trial run. If the cranks are noticeably asymmetrical relative to the seat tube (that can also be measured), with one being over 5 mm closer to it than the other, I’d use the spacer to correct it. If, because of that, you need to move the DS crank using a spacer (and have a 51.5 mm front chainline), it shouldn’t be a big problem as far as chainline is concerned (1.5 mm more than the rear chainline of 49 mm – not perfect, but far from dramatic).

bear in mind 😉 not bare in mind

Good catch – thank you. Fixed it.

Let me know if you notice any other “bed spilling.” 🙂

I plan to use a road crankset and a MTB 11 speed cassette on a 142mm wide hub.

My front chainline is basically a road standard chainline (43.5) because I use a road crankset and a 68mm bb.

My rear chainline is dictated by the axle spacing (142mm) and the cassette (MTB cassette). The 142mm spacing is now also common for road bikes so that shouldn’t make my chainline in the rear differ from my chainline in the front. Regarding cassette width: https://www.lightbicycle.com/newsletter/Bike-Freehub-Cassette-Compatibility-Manual.html says that a 11 speed road freehub body can take 11 speed MTB cassettes if a 1.85mm spacer is used. Conclusion: 11 speed road cassettes are 1.85mm wider than 11 speed MTB cassettes. But https://bike.bikegremlin.com/1232/bicycle-cassette-compatibility/ (the info about 11 speed Road vs MTB sprocket width and sprocket spacing) says that 11 speed MTB cassettes are ~1.76mm ((3.9-3.74)*11) wider than 11 speed road cassettes. So are 11S MTB cassets now wider or narrower than 11S Road cassettes? One source is wrong here (directionally, not about the exact number) or my logic failed.

Hi Nic,

Thanks for the support. 🙂

Regarding this topic, see chapter 11# here, and the linked comments and replies:

https://bike.bikegremlin.com/1232/bicycle-cassette-compatibility/#11

Basically (TL/DR):

Shimano 11-speed road and MTB cassettes can be considered to be identical when it comes to shifting (do note that road shifters will not work with MTB RDs and vice versa, different cable pulls, so those still have to match).

However, freehub body that can take an 11-speed road cassette needs to be wider (longer actually, the left-right dimension). Because road cassettes have smaller largest sprocket that can’t overhang the hub flange. If the freehub body were narrower, the largest sprocket would get stuck against the spokes.

11-speed MTB cassettes can overhang the hub’s flange, so the 11-speed MTB cassettes fit freehub bodies that are designed for 8 speeds (and 9 speeds etc.).

In terms of chainline, since the cassette sprocket width is practically identical, and the smallest chainring is placed at the end, road and MTB cassettes can also be considered to be identical.

The main difference is that 11-speed road hubs have their right flange a bit closer to the centre, to allow for a longer freehub body (for mounting an 11-speed road cassette).

For more details on this, see my video:

How the number of speeds affects rear wheel strength

I didn’t understand the point about the flange overhang (can’t visualize it because I don’t know what you mean by flange). But it isn’t really important in practice.

But based on what you said (and know) is it possible then that the info on the light bicycle website above is correct (i.e. that a 1.85mm spacer is required if you use a 11 speed MTB cassette on an 11 speed Road freehub – all Shimano) ?

Yes – that spacer is needed and it will be fine with it.