This article explains basic things about bicycle rear hubs, i.e. rear bicycle wheel hubs.

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

Table Of Contents (T.O.C.):

- Rear hub’s role

- Single-speed hubs

- Internal gear hubs

- Hubs with a freewhell, and freehubs with a cassette

- Dimensions

5.1. Boost hubs

1. Rear hub’s role

Rear bicycle hub has one main role, that is allowing the wheel to turn freely, while keeping it attached to the frame at the same time. Also, unlike the front hub, the rear hub has another important role: transferring driving force of pedalling to the rear wheel (usually, but not necessarily through chain and rear sprocket).

They consist of an axle, bearings and a body that has wheel spokes attached to it. There is also at least one sprocket for transferring pedalling power to the rear wheel. Three basic hub types are one geared (single speed, or even fixed gear) hubs, internal gear hubs and external derailleur hubs (with cassettes).

2. Single-speed hubs

The basic hub design. Power is directly transferred to the wheel (hub body) from the attached sprocket. It often has coaster brake installed. Since there is (by default) no external chain tensioner, it is often mounted in a frame with horizontal dropouts, which allows for chain tension regulation by moving the hub front and back.

This model has threads for screwing two sprockets – one on each side. This allows for two different speeds, but in order to use the other, chain needs to be taken off and the wheel turned.

This one also has offset mounting bolts, so that chain can be tensioned even on frames with vertical dropouts.

Single speed hubs can be used on frames with vertical dropouts, if they have off center mounting bolts (like the hub in the picture above), or if an external chain tensioner is mounted.

Good solution for modern frames with vertical dropouts.

Another solution I came across, quite exotic, is an eccentric bottom bracket shell:

These hubs often come with coaster brake. By turning pedals backwards, braking force is activated. A good solution for leisure riding in flat land areas.

Special subgroup are fixed gear hubs. These hubs don’t allow coasting – whenever the rear wheel is turned, rear sprocket runs also. It is fixed to the hub body. Advantage is the opportunity of riding backwards. The flaw is that pedals keep turning, even when that is not convenient (avoiding obstacles, or a fast downhill ride).

These hubs are practical for shorter distances in flat land areas. Their main advantages are simplicity, durability and low cost.

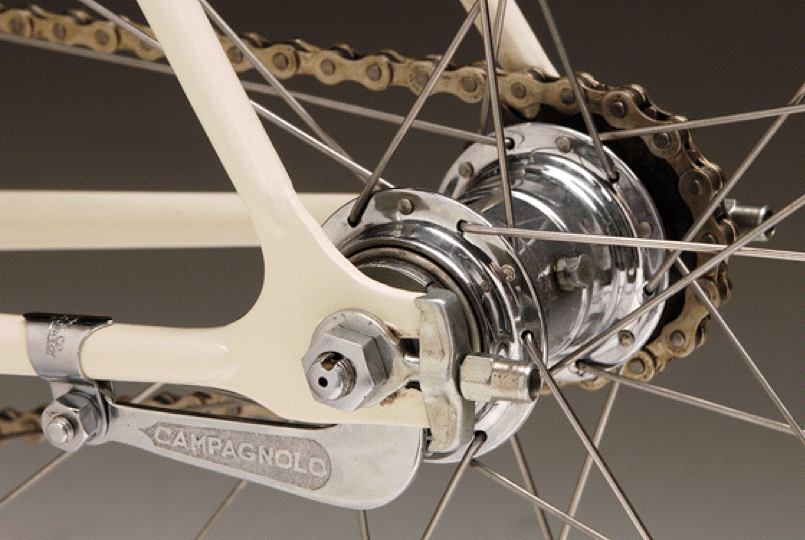

3. Internal gear hubs

They also have one sprocket and all the limitations of mounting singlespeed hubs also apply to these hubs. They have a long history, from the beginning of the 20th century and famous English three speeds. Today most popular models have 7-8 speeds. The gear changing implementation is a topic for another blog, but the important thing to know is they allow gear changes when completely stationary, no wheels spinning (e.g. while stopped at a traffic light).

Gear changing mechanism is well protected from the elements, packed inside the hub body. This makes internal gear hubs good choice for very wet, or very cold conditions. This is a system that allows changing gears in temperatures lower than -15 degrees Celsius.

Thin chain comes out of the hub, pulled by a cable. It is used to change gears.

Main drawback of these hubs is harder servicing and harder, more complicated wheel dismounting (when fixing a flat etc).

4. Hubs with a freewhell, and freehubs with a cassette

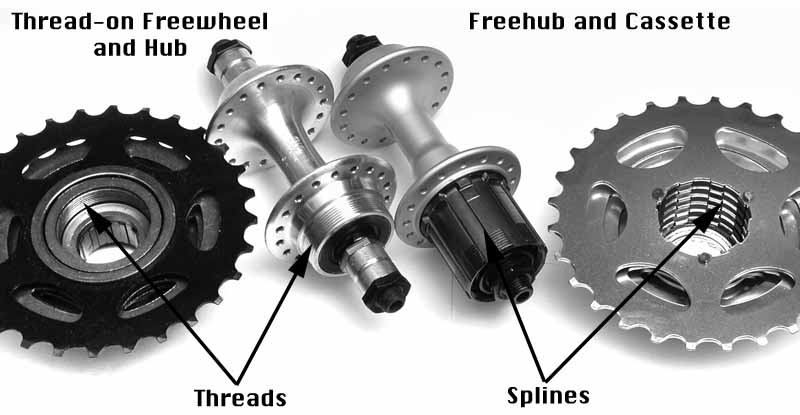

A common cause of confusion: the first standard was a hub with threads for screwing a freewheel on. It was popular until late 1980-s. Then a freehub + cassette combination started becoming popular. The picture below shows a hub with threads for frewheel and a freewhil, alongside a freehub with a cassette:

Detailed explanation of differences between freewheel and a freehub is given in this post:

Freewheel vs freehub (separate article sections explain the newer Hyperglide+ and XD freehubs)

Threaded hub has threads for screwing the freewheel on. The freewheel holds a cluster of sprockets and a ratcheting mechanism that allows free backpedaling (and coasting), while locking when pedals are turned forward, driving the rear wheel.

Freehub has installed cassette holder with splines, and a ratchet mechanism. This patent allows for a more precise machining, allowing the cassette to be totally perpendicular to the hub axle, i.e. being parallel with the rear wheel. Thread-on frewheel can never be this precisely parallel, because it is very hard to machine threads on both the hub and the cassette to reach perfect alignment when screwed together.

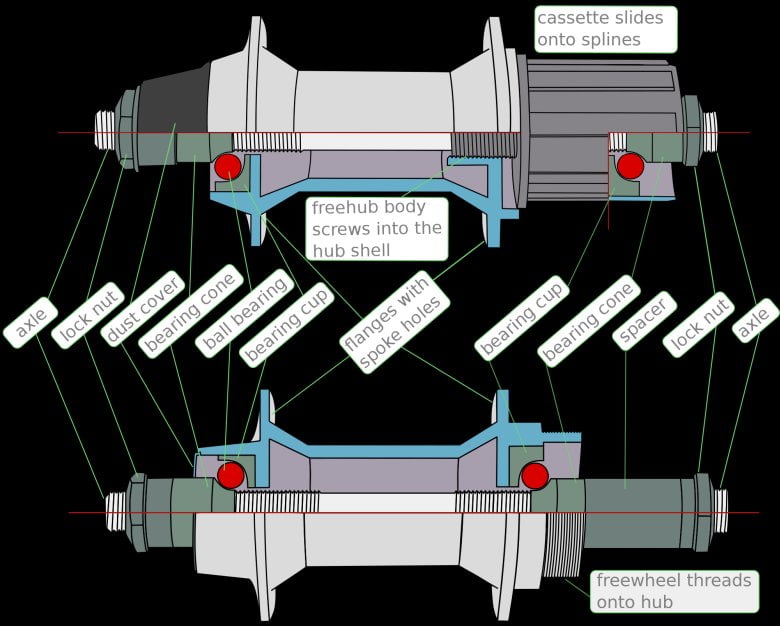

Another advantage of freehubs is the bearing position. Intersection is shown in the picture below:

Note the distance of bearings (red). Freehub has a lot more stable and secure design, with bearings at the very ends of the hub.

The spot where hub takes the most torque is where the sprockets are mounted and pulled by the chain. Freewheel hub has bearings placed almost in the middle of the hub, giving long leverage for sprockets to tug the axle. That is why hubs with freewheels were known to experience broken axles, especially with larger number of sprockets (therefore longer part away from the right bearing, giving stronger leverage to break the axle). This standard should be limited to 6 sprocket freewheels, maximum 7. Anything over that number (wider cluster of sprockets) is very likely to cause breaking the rear axle.

Note:

Technically, some freehubs also suffer from poor bearing positioning – as discussed in my video about the DT Swiss freehub design problem. Apparently, cycling industry is run by marketing, not good engineering (my article about the cycling industry nonsense).

Freehub is definitely superior patent, compared to freewheel. For easier real life recognition, here are pictures of hubs with mounted sprockets:

Spockets are just slided onto the freehub, then locked in place with the lockring.

5. Dimensions

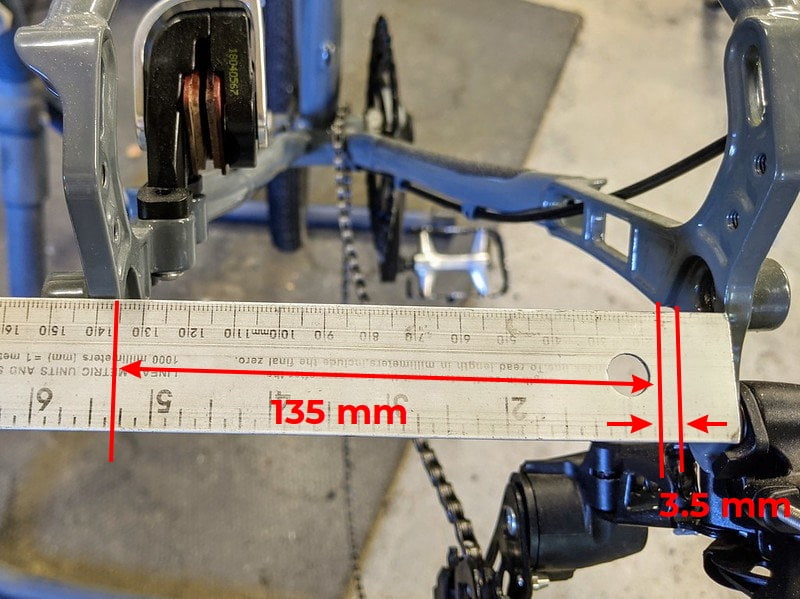

There is another variation in standards. A typical road bike rear hub is 130 mm wide, while an MTB freehub is a little wider: 135 mm, allowing more lateral strength. The newer standard of MTB rear hubs for extreme riding conditions is made even wider (with matching frames with wide dropouts), so the wheels are even stronger. There are now: 142, 148, 150 and even 158 mm wide rear hubs!

Old standards are 120, 126 mm etc. The width measured is the outer one of the hub parts that face the inside of the dropouts. The term still used for this dimension is “OLD” (Over Locknut Distance), although many modern hubs with “industrial” bearings don’t have locknuts. On cup and cone hubs (that used to be the only one available in the past), the outermost nuts were used to lock the cones in position by counter-tightening them, so they were called “locknuts”.

The nuts holding the hub in place and the axle width are not measured. Only the distance that stays inside the frame dropouts.

Another important dimension is the freehub cassette spline width:

- 8 and 9 speed hubs have the same spline width, they are 100% compatible. They can take a 10 speed cassette with using a 1 mm wide spacer ring.

- There is a special Shimano 10 speed only hub (rare), that is too narrow for any other but a 10 speed cassette – both road and MTB. 10 speed cassette is narrower than 8, 9 and 11 speed one. This freehub was manufactured for a short period, but is no longer popular.

- 11 speed MTB freehubs are the same as 8 and 9 speed ones. 11 speed MTB cassette is as wide as an 11 speed road cassette, but the biggest sprocket (nearest to the spokes) has it’s inner part (the one close to the hub) a bit cut out, so that the cassette can sit closer to the wheel, going a bit over the hub.

- 11 speed road freehubs have wider splines than all the others. In order to use 8/9 speed cassette on this hub, a 1.8 mm wide spacer is required. For mounting a 10 speed cassette, an additional 1 mm spacer is needed (the one used when mounting 10 speed cassette on 8/9 speed freehub). So 1.8 mm + 1 mm.

- New Shimano and SRAM freehubs, mostly intended for 11 and 12 speed 1X (single front chainring) systems have their own freehub and cassette designs, that can’t be combined with any others. These are SRAM XD and Shimano XTR M9100 “SCYLENCE” freehubs. As well as oncoming (spring 2019) Rotor’s 13 speed freehub.

5.1. Boost hubs

“Boost” refers to MTB hubs that are wider than the standard width before “the boost” (resulting in a wider chainline).

The idea is to widen the hubs’ flanges, for a better spoke bracing angle, so that the wheels are stronger, and to provide more width for rear suspension linkage (thanks to the now widened chainline).

The front hubs were “boosted” from 100 mm to 110 mm.

Rear hubs? There are a few more “flavours” to it:

For a long time, rear MTB hubs were 135 mm wide.

Then, they were widened to 142 mm, to enable faster and easier “thru-axle” wheel mounting.

With 142 mm hubs, the chainline is the same as with the old 135 mm hubs, and they have the same flange distance, only the hub’s ends are a bit wider, to allow them to be mounted in thru-axle frames with special “steps” that hold the hub in place, letting you easily screw in the “thru-axle” with the bike standing on the (still not properly fastened) wheel. Designing these “steps” with a 135 mm wide hub would result in the cassette getting stuck against the frame.

Source: bikeforums.net

- A 142 mm hub can be mounted in a frame designed for 135 mm hubs if you carefully grind down 3.5 mm on each end of the hub.

- A 135 mm wide hub can sometimes (depending on the hub’s model) be mounted in a frame designed for 142 mm hubs if you use some spacers. I haven’t done this with quick-release hubs, but most thru-axle 135 mm hubs can be “adjusted” to fit.

Of course, 142 mm was not enough for the cycling industry, so it was further boosted to 148 mm. This allowed for more width between the hub’s flanges for better spoke bracing angles, and widened the chainline allowing for more room to mount stronger rear suspension linkage.

The cynic in me says this was also very good for taking more money, as the new standards don’t fit the old frames.

For some hub and frame types, there are even “more boosted” hubs – like 150, and even 157 mm wide, but the principle is the same as for the 148 mm boosted hubs (i.e. you need a special frame, and “ordinary” hubs won’t fit).

For more detailed info on mix-matching freehubs, cassettes and other components, see the posts in the bicycle components compatibility section.

Help BikeGremlin

stay online & independent

This website is educational, free, objective, and not commercial

(sponsors don’t enjoy paying if you mention all the product downsides that you notice 🙂 ).

How much does a WordPress website cost?

If you find this site to be good and helpful,

and if $5 per month is what you can afford to set aside,

please consider supporting my work with a Patreon donation:

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

Hi there, really good article. I am looking for a freehub body for a Reparto Corse rear wheel which is basically Bianchi. The wheel has no existing freehub I so cannot reference and have Googled extensively but with no luck. Any ideas?

I’m afraid those are difficult to source (no idea where to find one).

Shimano hubsa are a bit less problematic in those terms.

As well as DT Swiss hubs.

For those one can often find spare parts, even if it’s not always easy, nor cheap.

Thank you! This was really helpful. I’m building myself a Trike and needed to figure out what to use for my wheels.

Hi Relja:

I was given a set of wheels Mavic Ksyrium SL for Roadbike (I think I the old-ish version), the wheels came with a Campagnolo hub. I understand the conversion to Shimano is very simple but I don’t know what freewheel I need to buy (All I know is that I need 11 speed).

The best I could find was a “Shimano HG”. Not sure what it means. mavic Web site is down at the moment.

Wheels may be a bit old but I know they are incredibly strong and light (I had similar set before).

Thanks again. I’m happy to share a photo but I dont know how.

Hi Alex,

“Shimano HG” probably stands for “Hyper-Glide,” their common cassette standard (apart from the Hyperglide+ standard on their newest MTB top-end XTR hubs).

Mavic website seems to be up and running (for) now, so I’d look there for a matching Shimano compatible freehub for the hub model at hand.

They list compatible freehub bodies for their current models, like this:

https://www.mavic.com/en-gb/ksyrium-sl-rr1223.html#product-description

Relja

I am working on a pedicab build and am wondering if you know of a hub that can have say a standard 6 or 7 speed cassette on one side that would be where it typically is on a bike frame, and also a sprocket on the other side that would have a separate chain connected to the rear axle to drive the two rear wheels. Thanks!

Hi Cam,

There are rear hubs that have both fixed gear and freewheel mounts, like this one:

https://www.tritoncycles.co.uk/components-c9/hubs-and-spares-c120/hubs-c591/ultra-new-32h-rear-track-hub-fixed-freewheel-p7372

Though do note that the fixed-gear side will keep the hub turning for as long as the chain is moving and vice-versa – as long as the hub (i.e. the wheel) is turning, the chain will be pulled. For either direction.

Edit:

The spacers on that hub are most probably designed to accommodate a single-speed freewheel. So a longer axle and some more spacers will probably be needed to accommodate a 6-speed freewheel. Wheel dish will also be severely affected, so I wouldn’t expect it to make for a very strong wheel (especially for any lateral loads).

for the people that have an older 126 mm rear spacing bicycle there is no need to bend that frame out to fit a 130 mm rear hub,you do exacty the opposite and re-space the 130mm or 135mm rear hub down to 126mm to fit a new 7 speed cassette or 6 speed freehub if you like,you just use a smaller spacer on the hub and thinner locknuts and thats all that is needed and a different size axle of course,most older cup and cone hubs are very easy to re-space and i have even re-spaced a 126mm hub up to 135mm,its very easy to do if you have the spare parts,most older hubs are very much the same width