There’s been a long trend of ever increasing number of speeds on bicycles. From single speeds, “tenspeeds”, over 18 speeds (bicycles with 3×6 chainring setups), to modern “1X” trends with only one front chainring and 10 to 12 rear chainrings (“sprockets”). This post will try to answer the question: how many speeds are really needed for cycling?

1. How many speeds is the best for a bicycle?

In order to answer, it is necessary to understand how derailleurs and gearing work, as well as the construction of the rear hub. Which are explained in the following chapters.

2. Speeds and gear ratios

Short explanation:

It is important to have gearing slow enough for steep climbs and fast enough for wind at one’s back, without large gaps in between (equivalent of a large gap would be shifting from 2nd to the 4th gear in a car).

Detailed explanation:

Bicycle gearing is explained in detail in this post: Bicycle gear ratios – speeds.

3. Derailleurs

Short explanation:

There are two groups of derailleurs

- Front

- Rear

There are three derailleur systems

- External cable activated derailleurs

- External electronically controlled derailleurs

- Intergnal gear hubs (only rear group)

This explanation will be limited to external, cable activated derailleurs. Internal gear (rear) hubs, as well as electronic derailleurs are a special case and will need a special topic. To just put a short explanation: internal gear hubs are good for riding in very cold conditions (colder than -15 degrees Celsius) and electronic derailleurs are similar to cable activated ones but a bit more expensive, use batteries and automatically trim the front derailleur cage – good for racing.

For front derailleur, number of (front) chainrings is important (is it 2 or 3).

For rear derailleur, also, the number of rear sprockets is important.

For both the front and rear derailleur, these two things are also important:

- The size of largest and smallest chainring (sprocket).

- Difference in tooth number between the largest and the smallest chainrings. This directly influences gear range – how fast is the fastest gear and how slow is the slowest one.

Detailed explanation:

Front derailleur functioning is explained in the post: Front derailleur.

This article explains how the rear derailleur works and how the number of rear sprockets influences sensitivity of the RD: Rear derailleur.

4. Front derailleur – number of chainrings

One, two, or three front chainrngs?

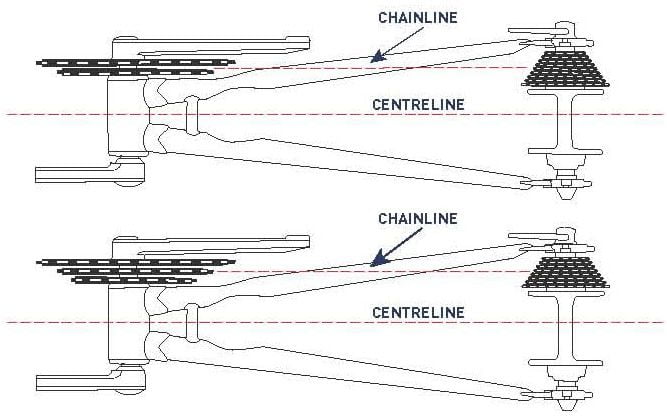

Front chainrings (and derailleur) make big changes of gear ratio (that is finely tuned with rear derailleur). Three chainrings up front give a very wide gear ratio, superior to having just two front chainrings.

For example: instead of having just two front chainrings, with usual tooth counts of 50-34, or 52-39, three chainrings will provide both wider and more tightly spaced gearing, like 30-39-50 (for road bicycles), or 22-32-44 (for MTB).

The main advantage of 2 chainring system is easier shifting, with less worry about cross chaining. This is important for competitive cycling, while for recreational cycling it simplifies shifting a bit, but one gets used to 3 chainring shifting quite quickly.

The advantage of one chainring system is lower weight and even simpler shifting. There is one shifter handle less and one derailleur less. However, either gear range, or gear spacing must suffer with this system. Usually both.

Here you can read more about the pros and cons of 1x drivetrains.

5. Rear derailleur and rear hub- number of “sprockets”

One, 6, 8, or more – 10, or 12 rear chainrings (“sprockets“)?

Functioning of rear derailleur and the number of rear sprockets are tightly connected. The basic problem is that with more gears, rear derailleur has a lot more chance for error: it needs to make smaller, more precise movements as the number of rear sprockets increases, since they are thinner, and more tightly packed.

Systems with 8 and less sprockets, there is a wide gap between sprockets. This enables RD to be less than perfectly tuned and aligned and still work well. Also the chain is thicker and stronger.

Also, shifter levers and cables often have some friction and some housing provides a wee bit of play. This affects systems with lower margin for error: the smaller spaces between rear sprockets, the narrower the chain – the less margin for error.

Going to more than 8 sprockets, to 9, 10, or more changes everything:

prices of parts are higher (chain, cassette), error tolerance is lower, because sprockets are more tightly packed, with smaller gaps. The advantage of narrow sprocket spacing is a bit quicker shifting at the back.

On the other hand, 6 and 7 speed systems are hard to find with a cassette rear freehub, just with a freewheel. Why having a freehub is an important advantage is explained in this post: Freewheel vs cassette. If minimal cost is priority, 6 speeds is probably the best choice though.

Still, if budget allows, quality rear hubs are made as cassette freehubs, which fit 8, 9 or 10 sprockets. Cassette freehubs for 6 or 7 speeds are getting harder to find.

6. Rear sprockets

For detailed explanation of the topic, look at this post: Speeds – rear sprockets.

7. Conclusion

Considering prices of parts (sprockets and chains), robustness, ease of adjustment and maintenance, gear ratio range and gaps, as well as market availability, gearing with 3×8 setup is an optimal choice.

3×6 is good choice if minimal cost is the priority.

Advantage of systems with more rear sprockets are a few more transmission ratios in between – slightly smaller gaps between gears and slightly quicker shifting when everything is set up properly (new clean cables and housing). Speaking of gears, the “fast” part of the cassette is similar – differences come with slower gears, where large gaps can even be useful – climbing a hill, with one change gearing becomes much “easier”.

For comparison, 8 and 10 speed MTB cassettes of the same range 11-34 teeth:

11-13-15-17-…20..-23-26….-34 8 speed MTB

11-13-15-17-19-21-23-26-30-34 10 speed MTB

Greater gaps are at the last two thirds of the cassette, where they shouldn’t matter too much, except for competition, racing. Same goes for road cassettes:

…..13-14-15-….17-19-21-23-…26 8 speed road

12-13-14-15-16-17-19-21-23-25 10 speed road

Does it pay to have less reliable, more expensive system, in order to get an in between gear or two that are used when climbing? Each must answer for themselves, according to their criteria. For short distances on flat ground, one speed is often an optimal solution. For top racers, 2×11 setup is worth every cent and every gram.

8. Personal opinion of the author

I believe that more than 8 sprockets at the back, as well as wheels with less than 36 spokes are the biggest frauds in the cycling industry. At the expense of consumer, they are marketed as “improvements”, “upgrades”, but hardly bring anything measurably better.

This post explains the spoke count problem: Wheels and spokes.

Last updated:

Originally published:

Related post – Bicyle equipment (“groupset”) classes:

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/bicycle-how-many-speeds-article-comments.151/

Hello Relja, (sorry if seems I’m bothering you). I was thinking about friction shifters and pull ratio of 1:1.1 : and I worried that maybe the friction shifter would finish the “run” before all the cassette is “finished”.

given that there is a limited amount of cable to be pulled I’m worried that the shifter would need a large diameter = is not able to shift all sprockets.

let me know if I wasn’t clear. Bye

Hi Fabio,

Good thinking and quite sensible questions. To answer:

Friction shifters have a lot of total cable pull, so I’d be surprised to see that happen.

To be on the safe side, the calculation is, roughly:

( (Cassette width) minus (one sprocket width) ) all divided by the (RD movement ratio) = total amount of needed cable pull to shift across the entire cassette.

(CS_WD – SP_WD) / RD_MR = TN_CP

Measuring a shifter’s total cable pull can easily be done by having the shifter pull the cable all the way, marking where the cable exits the shifter, then using the shifter to release as much cable as it can release. The distance between the marking and the shifter’s cable entry/exit is the total cable pull of the shifter.

Make sure to put some tension on the cable when marking and measuring.

I’m not sure what you are referring to by “plastic curve” in your other comment.

Ok, thank you. I’ll think about it.

Regarding the SRAM RD differently from Shimano, when the cable exit the housing it goes to the screw to be “pinched”. On the other hand, with SRAM the cable before reaching the “final screw” it goes in a sort or arch.

If I’m not clear jet, I’ll attach a pic to the mail regarding the rear hub mech.