This post explains important facts about bicycle rear derailleurs. From construction and parts, to important characteristics such as chain wrap capacity etc.

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

Table Of Contents (T.O.C.):

- How does the bicycle rear derailleur (RD) work?

- Rear derailleur bicycle frame mounting

2.1. Hook type rear derailleur mount

2.2. Standard mount rear derailleurs (RDs)

2.3. Direct mount rear derailleurs - Standard vs “rapid rise” rear derailleur

- Derailleur capacity – cage length

- Max sprocket size limit

- Number of speeds, compatibility

1. How does the bicycle rear derailleur (RD) work?

Rear derailleurs (often refferd to as RD) are used on bicycles with external gearing and multiple sprockets at the rear hub. They work on a simple, brute force principle: moving the chain sideways, until it slips off a sprocket onto the adjacent one.

This derailleur movement is usually operated via shifters (shifter levers), that are located on the bars (or somewhere at hand). Shifter cable is attached to shifters at one and and at the derailleur at the other end.

It consists of a metal cage and a spring. The spring moves derailleur to one side when the shifter cable is released, while the shifter cable, when pulled, moves it to the opposite side. It also has jockey wheels on a cage, with a spring, used to pull extra chain when changing to different sprocket sizes, so it doesn’t fall off.

2. On Shimano and SRAM derailleurs, the b-tension adjuster fine-tunes the height of the guide pulley. On Campagnolo derailleurs, the adjustment is done via a screw near the p-knuckle.

3. To adjust cable tension, use the barrel adjuster.

4. The guide pulley keeps the chain in line as it moves from cog to cog during shifts.

5. The idler pulley helps hold tension on the chain regardless of gear choice.

6. The mounting bolt connects the derailleur to the frame.

7. The parallelogram linkage lets the chain move left and right and up and down the cassette while remaining parallel to the cogs.

8. High and low limit stops are usually found near the b-knuckle but sometimes on the front of the parallelogram. The low limit (often marked L) prevents shifts into the spokes; the high limit (marked H) prevents the chain from dropping off the smallest cog.

9. The p-knuckle holds both the guide pulley and a spring that keeps tension on the cage to hold the chain taut.

10. The cable bolt pinches the shift cable in place. .

11. The cage keeps the chain in line between the pulleys.

First and only in-page advert:

Thank you for your support and understanding.

2. Rear derailleur bicycle frame mounting

There are three standards of rear derailleur attachment:

- Hook type (derailleur has a built in hook).

- Standard mount (frame must have a point for screwing the derailleur onto – derailleur hanger).

- Direct mount (a modern version of the standard mount, basically)

Which one of these derailleur mount types is used, depends on the frame rear dropout type:

2.1. Hook type rear derailleur mount

These RDs have a mounting hook built in, enabling them to be mounted on frames without any RD mounts.

In practice, they can often be mounted even on frames with a standard RD mount, if the frame’s standard mount doesn’t get in the way (either when mounting or during RD’s movement later on).

The way of mounting this derailleur type is shown in the pictures below:

2.2. Standard mount rear derailleurs (RDs)

These RDs are screwed directly into a mount on the frame. But don’t mistake this type of RD for a direct-mount type.

2.3. Direct mount rear derailleurs

In 2012, Shimano decided to move the rear derailleur a bit further to the rear. 🙂 And so the “direct mount” RDs were born. Why?

- This rearward movement allowed for easier rear wheel removal/installation. RD no longer needs to be pulled back, out of the way.

- Also, this enabled the RD to be tucked a bit closer inwards, i.e. not sticking out so much, protected from impacts. Hence Shimano named this new type of RDs “Shadow” (kudos to their marketing team).

These derailleurs require a compatible direct-mount frame mount.

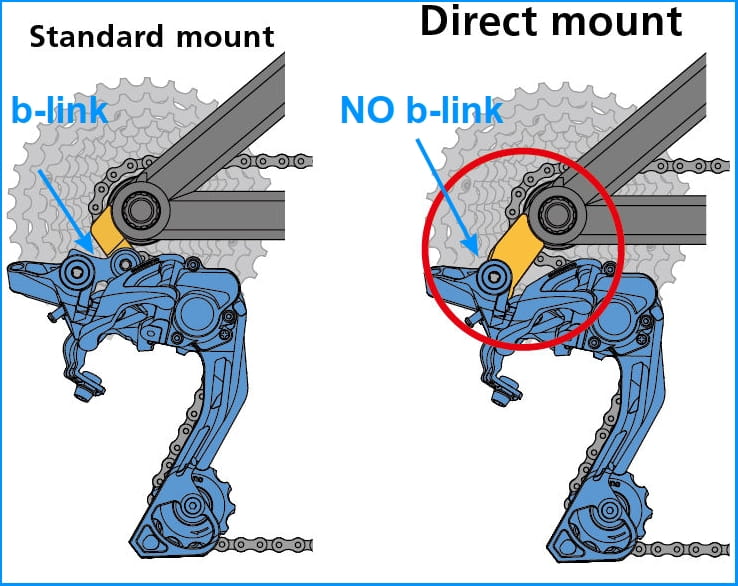

However, these RDs can also be mounted on a standard mount, if a “b-link” is used:

This drawing from the Shimano website nicely explains it:

Source: shimano.com

To reiterate:

- Standard mount RDs can’t be fitted on a direct mount hanger.

- Direct mount RDs can be fitted on a standard mount hanger if a b-link is used.

- Direct mount RDs are fitted to direct mount hangers without a b-link (i.e. directly).

3. Standard vs “rapid rise” rear derailleur

Most rear derailleurs have a spring pushing them outwards. When shifter cable is released, the derailleur moves outwards, towards the smaller sprockets. When shifter cable is pulled, movement is reversed – towards the wheel, bigger sprockets. This way of functioning is called “high-normal“, or “top-normal“.

“Shimano Rapid Rise“, also called “low-normal” derailleurs work the opposite way: spring pushes them towards the wheel, while pulling shifter cable moves them towards smaller sprockets. Same shifter levers can be used for both standards. If a shifter lever has gear indicator, if a rapid-rise is put instead of standard (or vice-versa, for rapid rise shifter levers), indicator will show “upside-down”. But shifting will work correctly.

4. Derailleur capacity – cage length

Derailleur capacity is a number of tooth difference between front and rear sprockets that the derailleur can compensate. When chain is put on the largest chainring up front and the largest sprocket, the chain needs to be long enough to wrap. Then, when chain is placed on the smallest sprocket at the rear and smallest chainring, there will be a lot of “extra” chain length that rear derailleur pulleys must “gather”, to keep the chain tensioned. These are both extreme combinations, with worst cross chaining, so not recommended in practice.

So manufacturer chain capacity data can be taken with some liberty, if the user is experienced and careful, never using extreme combinations.

Derailleurs come in three sizes: short, medium and long cage. Derailleur capacity is proportional to cage length. For wide range MTB cassettes with three front chainrings, it is practical to have a long cage derailleur. A typical narrow ranged road cassette and two front chainrings will make do with a short cage derailleur.

Shimano notes RDs as: SS (short cage), GS (medium cage) and SGS (long cage).

Example: if a bicycle has a crankset with 48-38-28 teeth, and a cassette that ranges from 11-32 teeth, then a needed RD capacity would be:

(48-28) + (32-11) = 20 + 21 = 41

This would take a long cage RD with over 40 teeth capacity

For a typical road bike setup with 53-39 crankset and a 11-25 cassette:

(53-39) + (25-11) = 14 + 14 = 28

A short cage RD with under 30 tooth capacity would suffice.

With 1x drivetrains, you only calculate the difference between the largest and smallest rear sprocket tooth count (since there’s only one chainring at the front, of course).

See here about: what if RD’s chain wrap capacity isn’t big enough?

5. Max sprocket size limit

Apart from RD capacity, an important characteristic of a RD is the maximum number of teeth of the biggest rear sprocket that RD can handle. For short cage road bike RDs, this is usually about 25, or 28, while long cage MTB ones often enable use of 32, 34, or even more teeth at the cassette.

6. Number of speeds, compatibility

A series of posts explaining what can be combined with what: Compatibility

MTB rear derailleurs from 6 to 9 speeds, and road RDs from 6 to 10 speeds are interchangeable and compatible. Slight difference in jockey wheel thickness is not a problem – a 6 speed RD will work on any number of speeds – up to 9 with a MTB and up to 10 with a road bike. It is the same ratio of derailleur cage movement per cable movement, so the shifter levers determine the movement and the number of “speeds”.

10 and 11 speed MTB derailleurs, as well as 11 speed road bike derailleur are not interchangeable. Different cable pull ratio and parallelogram movement for each. There are exceptions from these rules, so if some combining (mix-matchin) is planned, it is best to first read the post about bicycle rear derailleur compatibility.

If shifters used are indexed, shifter mechanism determines the amount of cable pulled for each gear, with each shifter click. So rear shifter compatibility needs to be accounted for. There is a difference in cable pull ratio for Campagnolo, SRAM and Shimano. That is why a SRAM rear derailleur will not work properly with indexed Shimano shifters (and vice-versa). With friction shifters (those that don’t have a click for each gear), this is not an issue.

So, one could say that if using indexed shifters, they will work as long as the RD is by the same manufacturer as the shifters. Though, apart from Campagnolo and SRAM, most other manufacturers are compatible with Shimano.

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

Last updated:

Originally published:

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/rear-derailleurs-explained-article-comments.136/

I am currently running with 3×9 setup. Planning to go 1×11 with shimano m5100. Is it okay if I use slx11 speed shifter? And also

2) shimano m5120 description is that 1×10 or 2×11. Is it okay if If I run it 1×11?

Hi Kyll,

M5120 should work with 10 and 11-speeds both 1x and 2x according to even Shimano specs:

https://bike.shimano.com/en-EU/product/component/deore-m5100/RD-M5120-SGS.html

The important thing is to pair it with a compatible shifter. M5000 series shifters should work for 11 speeds (with the M5000 series derailleurs).

11-speed M7000 series SLX shifters are listed to work fine with M5000 derailleurs on Shimano’s compatibility chart.

The RD-M5100-SGS rear derailleur is designed specifically for 1x drivetrains, so I would rather go with that, instead of the RD-M5120-SGS for a 1x drivetrain.

P.S.

I wrote an article explaining the pros and cons of 1x systems (compared to 2x and 3x).

Relja Novovic