This post explains bicycle wheel construction. What makes a strong spoked wheel, how many spokes is the optimal choice.

For explanation on how to remove and mount a wheel, read this post: How to remove a wheel.

Differences in wheel size: 26 vs 27.5 vs 28/29″ wheel sizes comparison.

Tyre size: tyre (and rim) dimension standards explained (e.g. ISO), which tyre fits which rim etc.

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

Table Of Contents (T.O.C.):

- Bicycle wheel role (function)

- Wheel construction

- Choosing the right wheel

3.1. The number of spokes

3.2. Rims

3.3. Hub type

3.4. Putting it all together - Conclusion

- Author’s personal opinion

1. Bicycle wheel role (function)

Wheel is used to carry the bicycle, of course. In order to fulfill it’s role, the wheel needs to be:

- True. Without any dens or wobbles.

- With the appropriate rear hub, depending on desired gearing. See the post: Bicycle rear hub.

- With the appropriate rim. Road bike will have a narrow, light rim, with sides suitable for brake pads, while an off road bike will have heavier, stronger rims, suitable for disc brakes.

2. Wheel construction

Wheel consists of hub (with bearings and axle), rim and spokes that keep it all together. Wheel stands on its spokes.

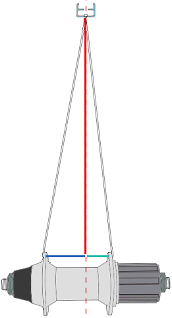

As shown in the picture above: when a rider sits on the bicycle, the load will be transferred over the fork to the wheel axle. Wheel axle will start loading the rim, through spokes with which they are connected. When the axle starts pushing down, and the rim is on the ground, he only way the axle can go down is if it somehow manages to completely unload the spokes in the lower part of the wheel. Spokes are easily bent, and the only way they provide some sort of leverage is when they resist pulling force – the one that tries to elongate them. So it is important to have the wheel trued and spokes tightened to appropriate torque.

Based on that principle, the whole wheel is trued and kept in line. By spoke tension.

In the picture above a trued rear wheel is shown. Since there is some space left for a cassette on the right hand side, spokes there start a bit closer to the axle center. That’s why, in order for the rim to be centered, right hand spokes are effectively shorter than the left hand one. Tightening right spokes moves the rim to the right, while tightening left hand spokes moves it to the left. That is how wheel is finely tuned and centered. Truing wheels will get it’s own post, but that is the basic principle of how it works.

Video demonstrating how to true a wheel (in over-recorded, Tarzan English, sorry 🙂 ):

3. Choosing the right wheel

3.1. The number of spokes

Over 50 years ago, most bicycles had 36 spokes on each wheel. British standard at the time was 40 spokes on the rear, and 32 on the front wheel. 72 spokes in total in any case. Only “fancy” racing bikes had less, usually 32 spokes on the rear wheel.

Then someone from the marketing got an idea: “Let’s make 32 spoke wheels. They will use less material, be cheaper to produce, but we’ll present it as an ‘upgrade, better, newer, like the wheels racers use!’ ” The result was weaker, less durable wheels, at the same (if not even higher) price. For an average user that doesn’t load bike heavily, these wheels were good enough to hold until the guarantee had passed. So everyone was happy (wheel producers a bit more than the others).

This trend was continued, so now there are wheels with 24, or even just 16 spokes! The main selling point of such wheels was they are lighter and more aerodynamic.

When comparing pictures above, it is clear that in the left picture the whole rider’s weight is supported by far less spokes, while in the right hand side picture, weight is distributed over couple of times more spokes. Left hand side rim needs to be stiffer and stronger (and heavier) in order to bear high load in just one place. Also spokes need to be stronger, thicker (and heavier). That is why low spoke count wheels aren’t so much lighter as the spoke number difference suggests. They are more aero, but 90% of drag is produced by the rider themselves anyway.

That is why these differences are very slight, important only for racers, competitors. However, difference that is very easily noticed is durability, reliability and strength of a wheel. Wheels with 36 and more spokes can carry more load, are more durable and easier to (keep) true. Even in case a spoke breaks, they don’t come out of true very much and can get a rider home. 40 spoke wheels can even be ridden for years with one broken spoke. 🙂 For wheel with 32 or less spokes, each broken spoke creates a problem.

The upper limit of spoke count is 40. Above that, little is gained in terms of wheel strength, nor in terms of wheel staying better true in case of one spoke breaking. If bicycle is not used for carrying heavy loads (over rough terrain), even 36 spokes is more than enough.

Steel spokes with brass nipples are the most robust choice on the market (from a renowned producer).

Discussion about this on the BikeGremlin fourm

3.2. Rims

Good rim should be decently stiff and as strong, as light and as durable as possible. Also if using rim brakes (and not disc brakes), rim should allow good braking traction and not easily overheat.

There are three popular rim materials:

- Steel

Steel rims are heavy, rust prone, brake pads slip more over them in wet conditions. - Carbon fibre

Carbon fibre rims are generally stiffest and lightest. Good choice for racers. However, they require special brake pad material (and braking is worse, except if disc brakes are used instead of rim brakes) and are less resistant to damage. - Aluminium

Aluminium rims are lighter and stiffer than steel ones. They provide the best braking performance. If made with double wall, they are also stronger than steel or carbon ones.

Double walled rims are much more durable, much harder to bend and come untrue:

3.3. Hub type

Hub needs to be with good quality bearings, so that it works good and lasts long.

Shimano offers the best bang for the buck when it comes to hubs. Hubs are chosen to match the use of the bicycle and the chosen spoke count.

According to use, they can be road, or MTB (off-road). MTB hubs are better sealed against water and dirt. Rear MTB hubs are a bit wider than road ones (135 vs 130 mm – with modern MTB hubs for hard road conditions are made 142, 148, 150 and even 158 mm wide!). This makes a bit stronger wheel to lateral load, since spokes are laced at a better angle. For definition of hub width, click on this link: OLD.

Front hubs are usually 100 mm wide, whether they are road, or MTB. Some modern off road hubs with thru axle have even more width, both the front and the rear hub.

3.4. Putting it all together

When choosing rims and hubs, it is important to pay attention to the number of spokes. 36 spoke hubs require rims with 36 holes – and vice versa.

4. Conclusion

Wheels are (apart from the frame) part that determines how well a bicycle rides. Good quality rims, hubs and spokes are a guarantee that wheels will roll well and last long.

An example of some custom wheel building challenges is given in the post: Custom built wheel for a great man.

In a separate post I wrote in more technical details about how to build a bicycle wheel, lacing pattern etc.

5. Author’s personal opinion

Wheels with less than 36 spokes are the greatest marketing fraud and those who are not racing should look for 36 spoke wheels. For heavily loaded touring, a 40 spoke rear wheel is more than welcome.

Two personal experiences:

During a ride home on a rainy night (when else? 🙂 ) I hit a pothole and a rear wheel spoke broke. I realised this only after arriving home, because the wheel just got a slight wobble – didn’t come out of true enough to be noticed during the ride, or to rub the rear brake. The wheel had 36 (not high quality) spokes.

During a group ride, a fellow cyclist hit a pothole – a second of not being cautious. A spoke on her rear wheel broke. It was a 24 spoke wheel. The wobble of the wheel was so big that it started rubbing against the bicycle frame. On the key chain I carry a spoke wrench, so we managed to true the wheel enough so she can “limp” home, but it still wobbled a lot.

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/bicycle-wheels-how-many-spokes-article-comments.143/

Hi Relja,just dropped in to say hello i hope all is well,Roger Musson is in the process of writing his 8th edition wheel building book,another one for the collection Relja cheers

Hi Relja, in your opinion should there be an equal amount of spokes front and rear on a disc brake bike or should there be more spokes on the rear wheel? Criteria: 1) equal chance of damage on rear vs front wheel. 2) appropriate stiffness front and rear.

I’m aware off the theoretical argument that there is more stress on the spokes of a disc brake front wheel compared to a rim break front wheel. But how much of a difference does this really make and how does this compare to the stress from hitting potholes or cornering where the rear wheel seems to be more challenged because there’s more weight on the rear wheel?

Hi Nic,

I would argue that the front and the rear wheels both need to be (equally) strong – and thus have the same number of spokes. Front wheel takes practically all the load during braking, and the rear wheel takes most load during riding.

Regarding the stress, I would argue that rim brakes put more stress on the rim and the spokes, while disc brakes put more stress on the fork. I’ve discussed that at 36:39 in the video: Science behind the spokes.

With a note:

Disc brakes put torque, while rim brakes put pulling forces on the rim and the spokes. Hence, radially laced wheels are a very bad idea for disc brakes (they are a bad idea for any wheel, but an especially bad idea for disc brake and driving wheels).

Relja

Makes sense. Thanks for your input and opinion on front/rear wheel spoke count! I woud guess the same based on the fact that nearly all commercially available disc brake specific wheelsets / bikes also have the same amount of spokes front and rear.