What is the best bicycle bearing grease? In this post, a recommendation for bicycle bearings grease will be given. For detailed explanation of various types of greases, as well as recommendation of grease for extreme riding conditions, look at this (long) post: Bicycle bearing greases – explained.

The mentioned (linked) post gives explanation why, by author’s experience and opinion, grease recommended in this post is the optimal choice (i.e. the best considering all the criteria, including the price).

Related posts are explaininig: Bicycle hub overhaul procedure and Bicycle bearing types and designs. Separate post deals with mounting (anti seize) pastes – not to be mixed with greases, and how often you should lubricate and service various bicycle parts.

Table Of Contents (T.O.C.):

- What is the best bicycle bearing grease and how to choose it?

- Which lithium grease to use?

- How to decipher labels of various standards on grease packages?

3.1. ISO label

3.2. DIN label - Short guide for grease shopping

- Exception

- Author’s recommendations

1. What is the best bicycle bearing grease and how to choose it?

There is often a debate among the cyclists and mechanics about what grease is the best for bicycle bearings. Some swear by “old axle grease that my (grand)father used to use…” Others recommend silicone, teflon, graphite etc. greases. After a lot of reading, researching and experimenting, the conclusion is the following (this is autor’s personal opinion, based on knowledge and experience so far):

Ordinary lithium grease (i.e. lithium soap based grease).

Dirt intrusion is the nemesis of bicycle bearings. Even worse than water intrusion. That is why it’s important to clean and re-lube bearings regularly – once, or twice a year (depending on riding conditions and mileage). Grease quality is less important – bicycle bearings don’t take much load and with enough dirt inside, even the best grease is useless.

2. Which lithium grease to use?

Grease label usually says “Lithium grease”, with, or without “Multi-purpose”. There is often a number of NLGI grease hardness, for bicycles it should be “2”, sometimes noted as “NLGI 2“.

This should be enough not to make a mistake. If there’s also written “complex” besides the “Lithium” note, or letters “EP”, that, except for a higher price, will not do any harm (nor much good either, at least for bicycle bearing lubrication).

3. How to decipher labels of various standards on grease packages?

Following advice from the previous paragraph, one can’t go wrong. However, those who want to be absolutely sure (and have no problems with noting important marks before going shopping) can read the following (shortest possible) instructions for deciphering standards’ labels.

Grease label usually has (often on the back) ISO, DIN, or both standard labels. They note which specifications the grease meets. How to read them?

3.1. ISO label

For bicycle bearing grease, label should be like this (bold is necessary, the rest can be one of the explained options):

ISO 6743-9, L-XCCEA-2

- ISO 6743-9: this is the name of the standard by which the label is given. 6743-9 is standard for classification of grease characteristics.

- L is ISO label for all the lubricants, while X is the label for greases. If there are no “L-X” letters, the product probably isn’t a grease.

- Instead of each letter C, there can be B, D, E, F, or G. It doesn’t matter. They are sorted from slightly worse than C (B), over slightly better (D), to the best possible (G). These letters mark highest and lowest (respectively) working temperature of a grease. The “better” a mark, the lower is the lowest and the higher is the highest operating temperature. For bicycle bearing lubrication, even BB will do.

- Letter E marks corrosion and water washout resistance. Instead of E, there can be F, G, H, I, or J – sorted from slightly better (F), to the best possible (J). E is the minimum required (and perfectly fine) for bicycle bearing lubricants.

- Instead of the letter A, there can also be letter B. It is not preferable, but won’t do any harm in practice. B marks presence of EP additives. These additives help grease bear extreme pressures and are completely unnecessary for bicycle bearing lubrication.

- The last mark notes the grease’s hardness (“thickness”), by NLGI standard grade. NLGI 2 grade is optimal for bicycle bearings. The rest are either too soft, or too hard. That’s why it has to be number 2.

Full, and rather long explanation of ISO 6743-9 standard labels and their meanings.

3.2. DIN label

If there is no ISO label, look for a DIN label (bold is necessary):

DIN 51502, K2K-30

- DIN 51502 is the name of the standard that classifies grease characteristics. Instead of 51502 there can also be 51825.

- K means it’s a roller bearing grease. Only such greases should be considered.

- 2 is NLGI grade hardness. All other are either too soft, or too hard for the application.

- After the first letter “K”, and before the number “2”, there can be some of the following letters (all the letters mark that grease has synthetic oils in it, which doesn’t do any harm, except that such greases usually cost more): E, FK, HC, PH, PG, SI, or X.

- Same, after the first letter “K”, and before the number “2”, there can also be letters P, or F. They note additives to the grease. They don’t do any help, nor harm (except for raising the grease price).

- Mark after thickness grade number, in this example it is a letter K, notes resistance to corrosion and water washout and highest operating temperature. Acceptable labels are also: G, N, P, R, S, T and U.

- Finally, minimal operating temperature in degrees Celsius is noted. -30 represents -30 °C. Here -20 is also fine, unless riding in colder than -15 °C.

Full, long explanation of DIN 51502 standard labels and their meaning.

4. Short guide for grease shopping

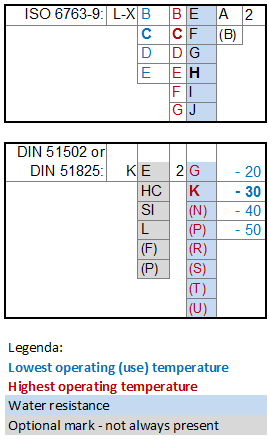

Table 1 shows a list of required marks for ISO and DIN standards. Desirable values are listed from the minimum required (top), then respectively to the best possible (bottom).

- Marks in brackets “()” usually mark EP additives, that a bicycle bearing grease is better off without, but they do no harm.

- With DIN standard, marks with a gray background may not be present at all.

- Bolded marks are exceptionally good values (all below are even better), marked just for reference, because any of the listed are perfectly good for the application.

- For DIN standard, same mark defines both highest operating temperature and water resistance.

- For detailed explanation of marks, see Grease labeling according to standards.

Table 1

Here are a few examples of perfectly “good labels” in both standards:

- ISO 6743-9, L-XBBEA2 – minimum required, NLGI 2 hardness, with decent water washout resistance and operating temperature range.

- ISO 6743-9, L-XDCIB2 – works in low temperatures down to -40 degrees Celsius (“D”), has exceptional water washout resistance (“I”) and EP additives (“B”).

- DIN 51502, K2K-20 – NLGI 2 hardness, decent water washout resistance and maximum operating temperature (“K”), no noted EP additives, minimal operating temperature of -20 degrees Celsius (“-20”).

- DIN 51502, KP2N-30 – EP additives (“P”), NLGI 2 hardness, high operating temperature and excellent water washout resistance (“N”), minimal working temperature of -30 degrees Celsius (“-30”).

5. Exception

For coaster brake hubs (hub brakes) – good choice are greases that can withstand high temperatures (generated when braking). Lithium-complex soap based greases, or, even better (especially if not sparing money, or they are already at hand) – lithium complex with molybdenum disulfide (MoS2).

6. Author’s recommendations

Author’s recommendation of greases from Amazon.com on-line shop is listed below (clicking on an image leads to the Amazon on-line shopping website). As an Amazon Associate I earn from qualifying purchases.

Note: listed greases are the ones I could find that are of good quality and with a world-wide distribution. Feel free to look for cheaper, locally available options. My 1st choice is local, Serbian made FAM FORPLEX 2 grease.

Update, December 2023:

Grease I’ve been using mostly over the past year is Motorex 2000 grease (also sold as “Motorex Bike grease”). Why? It is “officially” (by the manufacturer’s specifications) neutral towards plastic and many kinds of rubber (not to be used on DOT for brake rubber seals though). And it has a nice colour, but is mostly transparent, so I can easily see where and how much I’ve applied. 🙂 It is needlessly expensive for what I’m getting, but since I often work on other people’s bikes, and bikes are getting more and more plastic and carbon parts, I want to minimize any liability. This grease is calcium based.

Related post – Types and designs of bicycle bearings:

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/the-best-bicycle-bearing-grease-article-comments.142/

Hello, great article. What’s the best lubricant for Shimano flat pedals specifically the PD-GR600s? Thank you.

I’d say – the same as recommended in this article.

Dirt intrusion is the nemesis of bicycle bearings. So, for greases, just like with washing soap: regular use is more important than the “exceptional quality”. 🙂

Hello,

I have Mobil XHP222 lithium grease. Is it safe to use on aluminum parts? I have an aluminum full suspension frame. Can I use at the bottom bracket threads with shimano external aluminum bb cups, crankset axle, anodized pivot point bolts and shock mount bolt, integrated headset, fork steerer tube made out of aluminum etc. I heard if lithium grease mixed with water can cause corrosion on aluminum. Can I use this grease everywhere in my bike?

Hi,

For threads and other stuff that aren’t bearings, i.e. for preventing seizing, I recommend using anti-seize (mounting) paste.

Aluminium corroedes creating a thin layer of oxide that prevents further corrosion – unlike steel, where the corrosion keeps going.

However, salty water can eat through this oxide and keep the corrosion going, so in such conditions, a protective coat of paint, or water resistant grease are needed. High quality lithium complex grease can do a good job, though I’d say that most greases marketed as “marine” are with a calcium soap thickener.

Another problem is galvanic corrosion. Aluminium in contact with steel will start corroding, and get stuck so it can’t be (re)moved. The above mentioned anti-seize pastes are the best solution for preventing this.

Good quality lithium-complex grease, like the Mobil XHP222 can be used for lubricating any bearings, brake pivots etc. It can be used to prevent galvanic corrosion, but must be re-applied every 6 months (to a year, depending on the riding conditions). This goes for most greases, regardless of their thickener, and base oil type (lithium, calcium, etc.).

People swear by Mobex this and Park Tool that… nothing but Finish Line Lithium Grease with Teflon for me!