Eternal debate in the cycling world: how to lube and maintain a bicycle chain? There are those that seldom notice the drive chain, until it starts creaking really loud, or breaks. There are also those that religiously clean and lubricate their chains.

When it comes to those who do maintain their bicycle chains, there are many variations. Ranging from those who remove chain, clean it in an ultrasonic jewellery cleaner, to those that just wipe and drop some oil on a chain from time to time. After years of experience and experimentation, dozens and dozens of chains worn and replaced, I have come to some conclusions on the subject, which I will share in this article.

- For instructions on how to clean and lubricate a chain, as well as lubricant recommendations, see how to lubricate a bicycle chain?

- I also made a comparative overview of bicycle chain lubricants.

0. Disclaimer

All the information provided in this article, as well as on all of my websites, is to be taken as: “to the best of my knowledge”, or “as far as I know”. I have consulted experts of various fields (and still do), including mechanical engineers, especially when writing on this, rather “can-of-worms” topic, and info provided on my websites does agree with my practical experience, but it still is my opinion – based on my knowledge, education and experience. Different people, including experts, have different experiences and, often, different opinions. I’m sure there are, and will be, people who completely, or partially disagree. Even more often – there is and will be data (experiments, statistics, publications etc.) that might contradict, or seem to contradict my work when read/interpreted by a non expert. All of this is normal and to be expected.

People’s reactions to this article (along with the article on bicycle bearing greases) seem to range from taking it as a gospel, to taking it as blasphemy. Still – it is no more, and no less than: “what I have learned (through theory and practice) so far”. And, like all the other articles, it gets updated as new knowledge is acquired.

1. Construction of a bicycle chain

Chain consists of plates that are connected with pins. Over the pins there are rollers – used to make sliding over chainring teeth easier. Older version of chains had bushings over pins – between pins and rollers. Bushings helped reduce wear by both serving as a friction reduction themselves and by trapping and keeping chain lubricant between a bushing and a pin, as a “sleeve”. Bushing chain parts are shown in picture 1.

Picture 1

However, modern chains don’t have bushings – they are bushingless chains. In practice, this means they “absorb”, but also “loose” lubricant more quickly, and thus wear a lot faster. For details, look at this post: When to replace the chain on a bicycle. Picture 2 shows parts of a modern bicycle chain. Note the lack of bushings as the main difference.

Picture 2

Width of chain’s contact point with a sprocket is at least 1.6 mm (for sprockets for 11 speeds at the rear). Sprockets for less speeds and front chainrings are wider, and so is the width of the contact point. For details about dimensions see posts:

Bicycle chains compatibility

Bicycle cassette compatibility

2. Bicycle chain function and loads it bears

Bicycle chain’s function is to transfer pedaling force from the front chainring to the rear sprocket. For multi-geared bicycles with more sprockets (and chainrings) it needs to be able to transfer force when being used at an angle (i.e. cross-chaining).

Loads that bicycle chain bears are relatively low. Even for tandem bicycles (with two riders), the maximal power of the “engine” is about 2 kW when pushing really hard (for a few seconds), most of the time about 0.5 kW.

Speed at which a bicycle chain moves is below 5 km/h (top, when 53 toothed chainring is spun at over 120 rounds per minute).

3. Factors that affect chain wear

Since bicycle chain doesn’t take high loads or high speeds, the main factors that affect chain wear are it’s cleanliness and lubrication. It can be (over)simplified:

Chain lifetime = cleanliness + lubrication

Camshaft (timing) chains of motorcycles take higher loads and speeds, but last for over 50 thousand kilometres. This is because they are always lubricated (with motor oil bath inside the engine compartment) and enclosed from dirt and moisture (inside the engine).

That is why, to minimize wear, bicycle chain needs to be well lubed and as clean as possible (practical). Sanding pastes are usually made with friction materials suspended in some oil. So a lot of sand/dirt stuck to a chain will function as a sanding paste, wearing the chain faster. Note, only when dirt gets “inside” the chain – between the rollers and the pins, does it start to grind and wear the chain. So a chain can be dirty on the outside, as long as pins and inner sides of rollers are clean and lubed, there will be no problems. Vice-versa – a chain shinny clean on the outside, with sand between the rollers and the pins, won’t last for too long.

Techniques for cleaning and lubricating bicycle chains are explained in this post:

How to lubricate a bicycle chain

4. Chain wear measurement

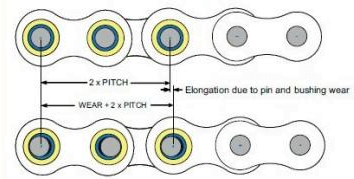

Bicycle chain wear is measured by it’s “elongation”. That is why a worn chain is often referred to as “stretched chain”. How does a chain get longer when worn?

Bicycle chains have 0.5 inch pitch, i.e. length of one whole link of a new chain is exactly one inch (2.54 cm). One chain link consists of one pair of inner and one pair of outer plates. In the picture 3, that is marked as “2 x PITCH”. As the pins wear, the distance between adjacent pins gets bigger – making the chain effectively longer.

Picture 3

Picture 4

When a chain is elongated for more than 0.5% of it’s specified length, it is time to change it. Techniques of measuring wear and consequences of riding with a worn chain are explained in the post:

When to replace the chain on a bicycle?

5. Characteristics that a chain lubricant should poses

A perfect bicycle chain lubricant should poses the following characteristics:

5.1. Good rust protection and resistance to water wash off.

5.2. Good adhesion, i.e. remaining between the pins and the rollers, without leaking out, as long as possible. Keeping the chain well lubricated and running quietly.

5.3. Cleanliness, i.e. not sticking dirt to itself and thus making the chain dirty.

5.4. Low price – so that chain lubrication doesn’t cost more in the long run than replacing chains more often

In the remainder of this post, these characteristics will be referred to as c.5.1. for the first one, c.5.2. for the second and so on.

As it will be explained later, when considering particular types of lubricants, noted criteria are often excluding. For example: a lubricant that is resistant to water is usually too sticky and collects much dirt; and vice-versa – a lubricant that is dry and doesn’t collect dirt is often easily washed out in the rain. That is why knowing conditions in which a particular bicycle is (mostly) ridden is important for choosing an optimal chain lubricant.

6. Viscosity of oils

Viscosity of a fluid is a measure of it’s resistance to deformation by effect of shear, or tensile forces. In plain English, the higher a viscosity of a fluid, the “thicker” it is. Honey is more viscous than milk, milk is more viscous than water etc. Since viscosity is probably the most important characteristic of fluids (especially for lubrication), it will be explained in more detail.

Viscosity is not a constant, but inversely proportional to temperature. With temperature drop, viscosity rises and vice-versa. Plain English: most fluids tend to thicken wen cooled and dilute when heated.

Dynamic viscosity of a fluid (also called absolute viscosity) is equivalent of the fluid’s resistance to flow inside a tube under pressure (i.e. pressurized hydraulic line). Simply put: how hard do I need to blow into a tube to move a fluid inside it for a certain distance. It is measured in pascal-seconds (Pa*s), in practice usually in order of magnitude mPa*s. Before acceptance of SI standard, it was measured in cP (centipoise). Noted by Greek letter mu (μ), while chemists often use letter eta (η).

Kinematic viscosity is the ratio of dynamic viscosity to density (specific gravity) of a fluid. Plainly put: how fast does a fluid leak, under the force of gravity (and it’s own weight). It is noted by Greek letter nu (ν), and measured in m2/s, though in practice mm2/s order of magnitude is often used. Before acceptance of SI standard, it was measured in cSt (centistokes).

Classification of viscosity for motor and gear oils was made by USA organization SAE (Society of Automotive Engineers) and SAE viscosity classification is often used for automotive lubricants. The reason it will be explained in this post is because for lubing a bicycle chain with oil, it is important to know how viscous (i.e. “thick”) it is.

For other lubricants, ISO viscosity grades are usually available as a reference. They are often noted in “old” measures, in cP and cSt, but easily translated to SI standard:

1 mPa*s = 1 cP

1 mm2/s = 1 cSt

Because of relatively low working loads and types of lubricants used for bicycle chains, this post will not take into consideration the following: non-Newtonian fluids and relation of kinematic and dynamic viscosity. Similarly, explanation of viscosity measurement methods and units is beyond the scope of this post.

6.1. SAE viscosity classification of motor oils

SAE viscosity classification defines two viscosity grade series: one with a “W” mark and the other without it.

- Oils with a “W” mark are monograde oils for cold (winter) use conditions (e.g. SAE 5W, SAE 20W, etc.). Made to be fluid (i.e. low enough viscosity) at low, or freezing operating temperatures. For each “W” grade, there is a defined maximal viscosity (and pumpability) at low temperatures, and minimal kinematic viscosity at the temperature of 100 °C.

- Oils without the “winter” mark are monograde oils for warm working conditions (e.g. SAE 30, SAE 50, etc.). They are defined by both minimal, and maximal viscosity at 100 °C temperature, as well as minimal high temperature shear stability.

- Oils that satisfy a certain cold (“W”) and warm classification conditions (by defined viscosity, pumpability and shear stability criteria) are called multigrade oils. Depending on which low and high temperature defined grade they “fall into”, multigrade oils are labelled as, for example: SAE 5W30, SAE 5W40, SAE 20W60 etc.

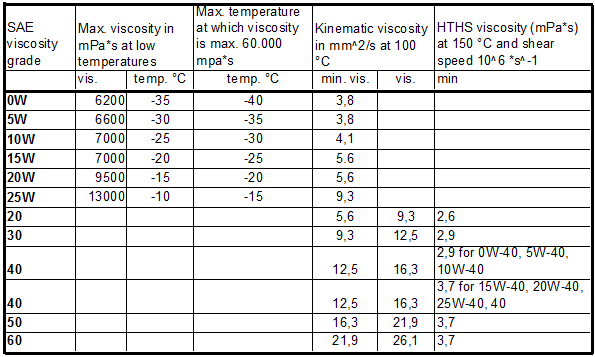

Table 1 shows standardised SAE viscosity grades of motor oils and viscosity values at reference temperatures.

SAE classification of motor oil viscosity grade

As shown in table 1, referent viscosities are given for freezing temperatures and for 100 °C. Since bicycle chains, even in summer heat, rarely reach temperature over 60 °C, for multigrade oils, referent number for viscosity comparison is the one before the “W” mark. For example: 15W40 and 15W50 oils have practically the same viscosity characteristics for chain lubrication purpouse (they aren’t literally the same, but without going into details too much, there won’t be a measurable difference in practice).

6.2. SAE viscosity classification of gear oils

Similar to motor oils, there are “winter” grades with a “W” mark (e.g. SAE 75W, SAE 80W etc.), and “summer” grades without the “W” mark (e.g. SAE 80, SAE 90 etc.).

Because of this post’s subject (bicycle chain lubricants), there is no need for a table, just a rough comparison with (for this use) motor oils of similar “thickness”:

- SAE 75W gear oil has similar viscosity to SAE 10W motor oil

- SAE 80 similar to SAE 15W, SAE 20W, SAE 20W-20

- SAE 85 similar to SAE 30

- SAE 90 similar to SAE 40 and SAE 50

- SAE 140 similar to SAE 60

For multigrade gear oils, similar to multigrade motor oils, the number before the “W” mark is relevant.

6.3. ISO VG viscosity classification

International organization ISO (International Standards Organization), in coordination with ASTM (American Society for Testing and Materials), DIN (ger. Deutsches Institut für Normung – eng. German Institute for Standardization) and others, made a common viscosity classification, called ISO VG (ISO Viscosity Grade).

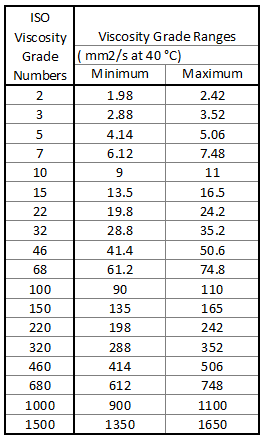

Classification applies mainly for industrial lubricants. Viscosity values are measured at a temperature of 40 °C, which makes them more relevant for bicycle chain lubrication reference, unlike API grades that use measurements at deep freezing and at 100 °C temperatures. Each viscosity grade has roughly 50% higher viscosity than the previous one, with minimal and maximal viscosity varying ±10% from the mid-point. Table 2 shows ISO VG.

ISO VG viscosity grades table

6.4. Comparative review of ISO VG and SAE viscosity grades

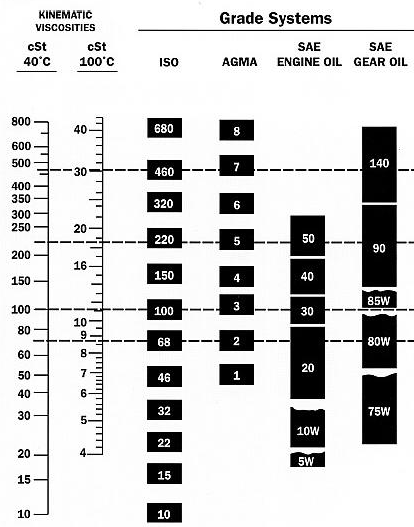

Because many lubricants don’t have an ISO grade noted on the package (only SAE), and ISO grade is much more “useful” when choosing a bicycle chain lubricant, picture 5 gives a comparative review of kinematic viscosities at 40 °C temperature of ISO and SAE grades.

Comparative review of ISO VG to SAE viscosity grades

As can be seen from picture 5, “thickness” of SAE 30 motor oil matches ISO VG 100 viscosity grade, while “thickness” of SAE 80 gear oil, depending on particular model and manufacturer, ranges from the lower borderline, to well below the reference ISO VG 100 “thickness” (i.e. viscosity).

7. Dry lubricants for bicycle chains

As Monty Pythons would say: “and now something completely different! ™” 🙂

After explaining viscosity, which is very important for liquid lubricants, a few words about dry lubricants for bicycle chains.

Dry lubricants are most often made based on paraffin wax, or PTFE (“Teflon”) lubricants. Sometimes as a mixture of both. The dry lubricants are usually suspended in some sort of liquid, or solvent, that allows them to flow between the chain pins and rollers. Liquid then evaporates rather quickly, usually after 2 to 4 hours, leaving a dry (or almost completely dry) film of lubricant. So dry lubricants are still dripped, or sprayed on the chain.

Advantages of dry lubricants:

Main advantage of dry lubes is that they attract less dirt – they aren’t as sticky as wet lubes. That is why they are good for dry weather use, especially if there’s lots of sand, or dust. They are also good for riding in the mud – less mud sticks to the chain, so it works better.

Disadvantages of dry lubricants:

Main disadvantage of dry lubes is they are rather easily washed off with water. So they are not good for rainy riding conditions. Even in dry they generally need to be applied more often than most “wet” (oil based) lubes, not lasting as long. Chain needs to be clean of any dirt or other lubricants, before applying them, so they can stick to it well and prevent dirt from sticking to it. When applied, 2 to 4 hours is needed for the solvent to dry, leaving just layer of dry lubricant. If a bicycle is ridden just after applying dry lube, the lube will fall off the chain more quickly and attract more dirt – beating the purpose of using a dry lubricant in the first place. This can be impractical if a chain needs re-lubing, but one needs to go riding immediately.

Another disadvantage of dry lubricants is they can’t replentish the lubed area after they are pushed aside – they don’t flow back like wet lubes. This especially affects multi chainring (multi-speed) drivetrains where cross chaining often happens. If there’s more load on the pedals when cross-chained (like riding up a hill), the problem is more pronounced.

7.1. Paraffin wax

Lubricants based on paraffin wax are good for dry riding conditions and for riding in sand and dust. Paraffin wax flakes off the chain along with grains of sand and dirt that might have gotten stuck to it.

Shortcoming of paraffin wax is that it isn’t mobile enough to replentish lubed surfaces after being displaced, while not being strong enough to resist being displaced after put under pedalling pressure. This is apparent after some water gets on a paraffin wax lubed chain – it quickly starts squeaking.

That is why paraffin wax lubed chains need to be re-lubed often. Also, chain needs to be completely clean and dry before lubing, so that paraffin wax can stick to it and prevent dirt from sticking to it.

Unless paraffin wax is bought, melted by heating, chain submerged in it, let to drip dry, excess rubbed off… then a “special” dry lube for chain needs to be bought, with a fluid solvent that dries off and a rather high price. Label usually says something along the lines of: “wax based chain lubricant”.

Some commercial paraffin wax based chain lubricants often have other dry lubricants added (usually PTFE), in order to improve characteristics. However, unless some oil is added as well (which beats the purpose of using a dry lubricant to prevent dirt from sticking to the chain), the problem of displacement from friction surfaces (and not flowing back) mostly remains!

Note: this test concludes that paraffin wax is the best bicycle chain lubricant, for all the riding (weather) conditions and by all the criteria. Important flaw of this test (by the opinion of the author which coincides with many users’ experience) is that it disregards strong pedalling in short bursts (when riding out of the saddle up hill for example), which can (and does) displace lubricant out of the contact points that need lubrication. The test also disregards cross chaining that regularly occurs with multi-chainring (“multi-speed”) bicycles and switching from one chainring to another – which all “help” lubricant displacement. Like it was explained in this paragraph, paraffin wax doesn’t flow back once it is displaced.

7.2. PTFE (“Teflon”)

Polytetrafluoroethylene, shortened PTFE is often found under the name “Teflon”, which is a name registered by DuPont company. PTFE possesses great characteristics: it lubricates excellently, repels water, doesn’t let dirt stick to it. The only problem is how to make it stick to the chain, i.e. between the rollers and pins. Most PTFE “dry” lubes still leave a very thin, very fluid layer of some fine oil, to keep the PTFE in suspension and onto the chain.

In practice they are usually longer lasting than paraffin wax lubes, but tend to collect a bit more dirt than paraffin wax lubricants. Still, less “dirty” than “wet” lubes. This is probably because they have a bit of oil, not completely dry like paraffin wax based lubes.

7.3. “Ceramic” lubricants

Quotation marks are because “ceramic” lubes are usually ones containing boron nitride synthetic ceramics (of a hexagonal crystal structure). Sometimes they are added to dry, sometimes to wet lubes, but lubricants advertised as “ceramic” usually contain the mentioned boron nitride.

Boron nitride has a very high price. While it has good characteristics for reducing wear of parts that are subjected to extremely high temperatures, for lubricating bicycle chains there are cheaper dry lubricants with good enough normal temperature characteristics. Graphite is the first that comes to mind – it is cheap, and even has good high temperature stability as well, though the latter is irrelevant for bicycle chain use.

7.4. Other dry lubricants as additives (MoS2, graphite etc.)

Besides the above mentioned, chain lubes sometimes have another dry lubricant added, such as molybdenum disulfide (MoS2), graphite or some other, more “exotic” additive, i.e. dry lubricant.

The more a lubricant gets dry when settled on a chain (because even completely dry lubricants are usually in some solvent that evaporates after getting applied onto the chain), the more chance a dry lubricant additive has to make a difference. Usually in terms of less dust and dirt sticking to the chain, or reduced friction and wear.

With completely dry chain lubricants, special additives are often also advertised as something that will improve corrosion and water washout resistance, but as far as the author’s knowledge goes, this is more a good marketing, than a fact. Bicycle chains don’t bear enough pressure for dry lubricants to form a protective film, that would resist water washout. If there’s not some kind of oil added, there can hardly be much water resistance. Usually, the more (and the more viscous) oil, the better water resistance, but the more dirt stuck to the chain. And vice-versa.

7.5. Dry lubricants that are still a little wet

As it was mentioned in chapter 7.2. (PTFE), some dry lubricants, even after applying them to the chain and leaving to dry, remain a little liquid, a bit “oily”. They are somewhere in between the wet and dry lubes, in terms of water (both washout and rust) and dirt resistance.

They can be made with lots of dry lubricant additives and high quality ester oils that stick well to the metal. They can also be just a marketing hype of people selling ordinary “thin” lube at a high price.

These lubricants are often advertised as “universal”, “all (weather) conditions”, “road and off-road” and similar, since they are not “pure” dry, nor wet lubricants.

8. Wet (liquid) chain lubricants

Wet chain lubes are usually based on some kind of oil, with, or without other additives (usually other wet, or dry lubricants). Different wet lubricants have different characteristics, with the important ones for lubricating bicycle chains listed in chapter 5.

8.1. Wet lubricant viscosity and it’s effect on lubricant characteristics

Lubricant viscosity (explained in chapter 6.) affects many characteristics of lubricants. Primarily it affects the water resistance (c.5.1.) and the amount of dirt that gets stuck to the lubricant (c.5.3.). The more viscous (thicker) the lubricant is, the more it will be resistant to water washout, but it will also attract more dirt. Vice-versa – “thin” (low viscosity) lubricants usually don’t get as dirty, but are more easily washed out by rain.

This effect is practically independent of particular lubricant’s properties. For example, a lubricant that is resistant to water washout will be even more resistant if more viscous, and less resistant if “thinned”. It may still be better than another lubricant that isn’t resistant to water washout, but viscosity has a significant effect on a wet lubricant’s characteristics and performance, besides the lubricants inherent characteristics.

Another thing to consider is that viscosity changes with temperature change. The colder it is, the thicker a wet lubricant gets, while in summer heat viscosity (drastically) drops.

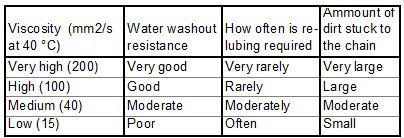

Because of all this, each must choose for themselves an optimal wet chain lubricant viscosity, based on riding conditions (temperature, rain, dirt, sand etc.) and how often they (want to) clean and lube the chain. Trade offs are given in table 3.

How viscosity affects wet bicycle chain lubricant characteristics

As can be seen from table 3, low viscosity lube will need to be applied more often, but the chain will be a lot cleaner and a lot easier to completely clean before re-lubing. The importance of chain cleanliness is explained in chapter 3.

8.1.1. How to change a particular lubricant’s viscosity (Home brew)

As it was explained in chapter 8.1, it is important for a lubricant to have optimal viscosity for exploitation conditions. Lubricants are often sold in certain viscosity grades. If factory viscosity of a lubricant is too high, it can be diluted with some other, a lot less viscous lubricant, or with an oil paint thinner (i.e. odourless mineral spirits). Oil paint thinner evaporates very slowly, even in summer heat, so it will keep the lubricant less viscous.

Better alternative is thinning lubricant with diesel fuel (better D2, but Eurodiesel is OK too). Diesel will evaporate more quickly, but only after the lubricant has reached the important area between the rollers and pins. While the chain is freshly oiled, diesel will help cleaning the outside of the chain, so less dirt gets stuck to it. After diesel (partially) evaporates, lubricant will go back to almost (but not completely) it’s factory viscosity, being “thicker” between the rollers and pins, making it last longer and a bit more resistant to water washout. Diesel viscosity is usually around ISO VG 3 grade.

Using a thinner that doesn’t evaporate doesn’t give this benefit. Leaving the chain with all the pros and cons of a less viscous lubricant. Choice of optimal thinning method and lubricant viscosity is up to each user – depending on the riding conditions and chain maintenance “strategy”. A bit of a trial and error method.

8.2. Characteristics of various types of commercially available wet lubricants (i.e. oils)

After the importance and affect of viscosity on wet lubricant performance was (again) explained, now characteristics of most commercially available wet lubricants will be given, along with their suitability for bicycle chain lubrication.

Many lubricant characteristics are given from author’s personal experience and available data of the ingredients and properties. If Your experience differs and certain lubricant turns out to be great for your riding conditions and chain maintenance methods, then by all means stick to it! There are too many varying factors to make it possible to give one universal recommendation. So look at the given data more in terms of guidelines… I think not even computer software companies make better disclaimers than this. 🙂

8.2.1. Gear oil

Gear oils usually have EP (Extreme Pressure) additives. Like the name says, extreme pressures are needed for EP additives to form a protective layer. No matter how strong a rider, bicycle chain will not face such pressures. Besides not being of any use for this application, most EP additives are corrosive to aluminium (which is what many chainrings are made of). Finally, gear oils tend to collect more dirt than some other oils, while they aren’t proportionally more resistant to water washout.

Bottom line – avoid gear oil if possible. In a pinch, use as “thin” as possible, cleaning it off the chain and replacing with a better option as soon as possible.

8.2.2. Engine oil

Monograde engine oils, with SAE 10W, or even SAE 30 viscosity, thinned down with diesel fuel (from 4:1, to highly thinned in 1:4 ratio), can be decent bicycle chain lubricants.

Engine oils of lower API grade class (API SF, or API SG), preferably monograde, for petrol (not diesel) engines, are the better choice than modern, higher API class engine oils, because they contain less detergents and other (needles, or harmful for bicycle chain lubrication) additives. As was explained in chapter 6.1, in case of multigrade engine oils, the first mark (before the “W”) is relevant for determining viscosity for bicycle chains lubrication.

As far as viscosities go, SAE 30 is a decent summer candidate (“thinning” with diesel per one’s taste), while SAE 10W is OK for the winter (also with “thinning” if required).

Rough SAE viscosity recommendations for motor oils, for the summer:

SAE 10W use straight

SAE 30 thinned with diesel in ratio 3(oil):1(diesel)

SAE 50 thinned with diesel in 1:1 ratio

For deep freezing temperatures, fully synthetic motor oil, of 0W, or 5W viscosity is a good choice.

Engine oils are designed to work within enclosed engine compartment. That is why they are not water washout resistance champions, while additives they have don’t help with bicycle chain lubrication, quite the contrary. However, these shortcomings are not severe enough to make (much) measurable difference from other oil types. Of course, as the following chapters will show, there are better options. The main advantages of engine oils are availability (there are often left-overs after changing car/motorcycle engine oil), low price (sometimes 0 $ 🙂 ), and it’s not that much worse than other wet lubricants.

8.2.3. (Sewing) Machine oil

Fine machine oil, of a relatively low viscosity (usually ISO VG 15 to ISO VG 25). Often sold as “sewing machine oil”. It provides decent corrosion protection. Water washout resistance and amount of dirt attracted depend mostly on viscosity, like explained in chapter 8.1. and table 3. Quite fine, relatively chap and easily available chain lube solution.

8.2.4. Paraffin oil

Paraffin oil, often called “medicine paraffin oil”, or “cosmetics oil”, is a highly refined mineral oil. Viscosity varies from “thin” ones (ISO VG 20 to ISO VG 35), to “thicker” ones (ISO VG 46, or ISO VG 68 more often). Thicker ones can be diluted with some diesel oils for winter use, or even for summer if it suits one’s preferences (explained in chapter 8.1. and table 3).

Fine paraffin oil is not a champion of water, or corrosion resistance, but it is very clean. It doesn’t leave stains, and it’s relatively easily washed even from clothes. That is why it can be a good choice for summer and dry conditions.

8.2.5. Turbine oil

This is an industrial oil. It has very good resistance to water contamination, water washout and provides excellent rust protection. Also it sticks less dirt to itself (compared to most other oils of the similar viscosity).

It is usually made in ISO VG 32 and ISO VG 46 viscosity grades. For special purposes, also in ISO VG 68 and ISO VG 100.

Problem with turbine oil is that it’s usually sold by the barrels. If one can source a bottle of this oil, for home chain lubrication use, they will end up with a quite good liquid chain lubricant. Dilute it per personal preference with some diesel fuel (D2 preferably).

8.2.6. Hydraulic oil

Properties similar to turbine oils (in terms important for bicycle chain lubrication).

They usually come in “medium thick” grades – ISO VG 32 and ISO VG 46, but are produced in viscosity grades from ISO VG 15 to ISO VG 100.

They are easier to find in smaller packages than turbine oils.

8.2.7. Chainsaw (bar) oil

These oils have very good adhesive characteristics (they stick to the chain well). They provide good rust protection and very good resistance to water washout.

The main flaw of chainsaw oil is it tends to stick a lot of dirt as well. That is why it’s a good idea to dilute it with mineral spirits, or diesel, usually in ratios from 3(oil):1(diesel), to 1:4 ratio, depending on oil’s viscosity. This will allow for the oil to reach the important area between the rollers and pins, then (partially) evaporate, leaving slightly thicker chainsaw oil where lubrication is needed, but away from the outside of the chain where it could attract dirt. The outside of the chain should be cleaned as soon as the (diluted) lubricant is applied – before the solvent dries.

Usual viscosity of chainsaw oil is around ISO VG 100 (similar viscosity to SAE 30 engine oil). There are special “summer” versions of chainsaw oils, with viscosity around ISO VG 160.

8.2.8. WD-40

Many people ask about this, so it’s worth mentioning. WD-40 is a phenomenal invention, for many applications – but not for bicycle chain lubrication. Why? Because it doesn’t contain enough lubricant.

It can be used for cleaning (though there are cheaper, and better alternatives), removing rust (again – with better alternatives), and water displacement (which it is intended for). But if you use it for lubing your bicycle chain, frequent re-lubing will be necessary. It just doesn’t last decently long, easily flying off the chain.

9. Specialized bicycle chain lubricants

Some of these have been mentioned in the previous chapters, but this chapter “deals” with all of them together: lubricants marketed and sold as “bicycle chain lubricants”.

These lubricants are made by various, big or small, manufacturers. There are countless types and models: “dry bicycle chain lubes”, “wet bicycle chain lubes”, “dry, ceramic bicycle chain lubes”, “wet ceramic bicycle chain lubes”, and so on…

Ingredients are usually “special and secret”. Often, completely needless additives are noted, such as “EP additives that enable the lubricant to bear extremely high pressures…” – which are completely irrelevant for a bicycle chain lubricant, since it doesn’t face extreme pressures, no matter how hard one pedals. Other listed additives usually include one, or several, of the following: PTFE, “ceramics”, boron nitride, graphite (less often), special synthetic oils, (paraffin) wax etc.

What lubes marketed as bicycle chain lubricants usually have in common is that there are no clearly specified ingredients on the package, nor standards that the lubricant fulfils (in most cases). Not even a viscosity grade for “wet” lubes. They usually cost a lot more than “ordinary” lubricants. Prices usually range from 5 to 10 euros for a 100 ml bottle, while, for example, smaller amount of money buys a 1.000 ml bottle of chainsaw oil.

Are they good, are they worth it? This comes down to personal experience – riding conditions, priorities, chain maintenance and lubrication routine… lots of factors. There are some very good special commercial bicycle chain lubricants, with thousands of satisfied customers. There are also thousands of people happy with a bit of chainsaw oil mixed with some “thinner”.

Like it was said in the beginning of this post, the most important thing for long chain life is to clean and lubricate chain regularly.

Comparative review of various lubricants is in this post: Comarative overview of bicycle chain lubricants.

10. Sources

- http://www.maziva.org/izbor-maziva/motorna-ulja/ulja-za-cetvorotaktne-motore/sae-viskozne-gradacije/

- http://www.maziva.org/izbor-maziva/motorna-ulja/ulja-za-cetvorotaktne-motore/api-specifikacije/

- http://www.maziva.org/izbor-maziva/ulja-za-menjace-diferencijale/

- https://en.wikipedia.org/wiki/Viscosity

- http://www.df.uns.ac.rs/files/200/elvira_djurdjic_-_master_rad_(f1-125).pdf

- http://kkft.bme.hu/sites/default/files/LUBRICANTS%20LAB%20.pdf

- http://sheldonbrown.com/brandt/chain-care.html

- https://www.scribd.com/document/262044061/Velo-Friction-Facts-Chain-Lube-Efficiency-Tests

- http://www.ilpi.com/msds/ref/evaporationrate.html

Authors

Relja Novović – BikeGremlin

Coauthor:

Stevan Dimitrijević (dr of metallurgical engineering)

Author of the greatest site (blog) in serbo-croatian language about motor oils and lubricants:

https://motornaulja.blogspot.rs/

Clicking on the image below leads to the Amazon on-line shopping. As an Amazon Associate I earn from qualifying purchases.

Affordable bicycle chain lubricant (click on the image below to buy at Amazon – or look in a local store for any chainsaw bar oil):

Related post – Bicycle chain wear (elongation):

11. Apendix: Oil vs Wax for bike chain lubrication – video

Only cyclists use wax for lubrication – no other industry does that.

Why?

I did some tests and discussed the pros and cons of using wax for lubricating bicycle chains.

My conclusion is that the low loads and speeds allow us to get away with an inferior, but cleaner lubricant.

The video showing and explaining the differences between wax and oil:

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/bicycle-chain-lubricants-explained-article-comments.130/

Last updated:

Originally published:

Correction

The pedaling is smooth AND NOISES for approximately 150 kilometers.

First of all thank you for taking the time and trouble to post such a comprehensive article. It neatly puts in one place much of what I have read about the seemingly endless opinions on chain cleaning and lubrication. Its a subject which almost against your will cyclists find themselves drawn to. My own ‘two pennyworth’ as a 50 odd year cyclist and tandem rider for the past 20 years is this. I’ve used many different products over the years and to be honest I’m minded to think the really expensive products just aren’t worth the money. For several recent years I simply used GT 85 which is super cheap, easy to apply and does not attract too much grit etc. Unfortunately I read an article recently which suggested GT85 was not great and I’m now trying a 50:50 mix of chainsaw oil/white spirit, applied sparingly and the excess wiped off. I think its worth remembering in all of this that chains just aren’t that expensive unless you are a real enthusiast and it might well be worth not worrying over much about maintenance and simply replacing the chain every thousand miles or so. Also there is a line of thinking that the factory chain lubricant on a new chain is probably the best you will ever have on it so should not be cleaned off/replaced too prematurely. In 50 years cycling I have snapped one chain (on the tandem), I now go as far as carrying a spare chain/quicklink/chain splitter just in case.

Thanks for the comprehensive article. Just a comment and one question:

When I look at the TDS on 0w20 by Mobil 1, strangely the kinematic viscosity at 40C is 48 cst. Higher than mono grade SAE 10 oil, which has a cst of 32 at the same temp.

I am trying to find a reliable way to reduce the viscosity of oil for skate bearings. In all my reading, odourless mineral spirits evaporate the fastest, much faster than diesel and this wouldn’t be a good choice for longer term thinning. Some have suggested kerosene. Ideas? I am not looking for a thinner to help penetration then evaporate.

Thank you

Hi Eric,

0w20 is more viscous oil than SAE 10 at non-zero (i.e. non-winter-cold) temperatures, including 40c, so I’m not surprised by those values (48 vs 32 cst at 40C temp).

As for the thinning – kerozene is similar to diesel as far as I know.

It will not evaporate very quickly.

Just make sure to confirm it does actually mix with the oil you decide to use (mixing them in a clear, see-through, bottle).

Though I’m not sure why such a thin oil is needed for skate bearings.

Getting a wheel to roll for a long time when started by hand, with the skate in the air is one thing.

But getting it to roll smoothly under load, for a long time, is another.

For most applications where a lubricant is not re-applied on a very regular basis (weekly or even more often), I use grease, expecting it to provide a better, longer-term lubrication (and, thus, protection from wear as well).

In other words, if we’re talking about caged cartridge bearings for (small) wheels, I’d consider using a soft grease (NLGI 0 or similar).

Keep revisiting this excellent article. Personally I’m not a fan of viscous lubricants, especially in winter. In fact i do the opposite of most people and use a very thin oil in winter and a slightly thicker one in summer. My reasoning is that in winter you will attract more dirt and i favour a good wipe wipedown after every ride and reapply. Using ‘white lightening epic’ I am guessing similar to sewing machine oil. The chain stays really clean even off road in winter. In summer less filth means i have less maintenance and use a little thicker to last more rides. But still wipe religiously every ride. I do wash after a filthy ride. But I get good longevity and chains are cheap, my time to valuable. I’m going to try sewing machine oil ISO22 is £6.50 on ebay for 500ml. As I like thin oils I don’t need to add solvent. And any rate solvent only aids application. It will evaporate and you are back to a dirt attracting thick oil.

I love that disclaimer – “… all of this is normal and to be expected”. 🤣

Took me straight back to The Hitchiker’s Guide to the Galaxy.

Thanks for this article. It is quite enlightening. I feel better for having read it.

Keep up the good work

Cheers