If you’ve ever fixed bicycles, motorcycles, or any appliance with cross-head screws, you know how frustrating it gets when your screwdriver keeps slipping out, especially when trying to loosen a stuck screw. It doesn’t have to be like that. Let’s dive into this problem.

In this post, I’ll explain how to find a cross-head (Phillips) screwdriver that doesn’t slip out when unscrewing a tight screw. I will do that first, briefly. Then comes some history and standards explanation (including JIS) to provide a universal way of recognizing the good, well-fitting screwdrivers – and clarify what it’s all about.

In a separate article, I explained all the hex-bit size standards and types.

TL/DR

I had a problem with some cross-tipped screwdrivers more easily slipping and damaging screws on Japanese bicycles and motorcycles I work on.

In chapter 4, you can find a list of screwdrivers that work well (what I use, what works for me – and my friends).

In the first three chapters, I’ve explained why some screwdrivers suck and which types of cross-tipped screwdrivers exist (people often mix those, use the wrong screwdriver, mess up the screw, and then it’s a headache).

1. Good cross-head screwdriver

The goal of this article (and my research for it) was to help myself find a screwdriver that fits well and doesn’t cam-out. In other words: how can I tell, before trying (and buying), if a screwdriver will work properly with a bicycle, motorcycle and other cross-head screws?

Those who wish to know how I chose this screwdriver can read the following chapters. Still, for those who just want to know which screwdriver has worked very well for me, on both the American Phillips and on Japanese (bicycle and motorcycle) cross-headed screws, this is it (providing Amazon affiliate links for screwdriver pictures and price-comparison):

Wera Kraftform Stainless 3350 PH 2

Picture 1

Do you have to buy this one, or are there other good ones? Well, I’ve got some good and some bad news – which one do you want to read first? 🙂

- The Good news: yes, there are more than one manufacturer (and model) of good quality cross-head screwdrivers (some more recommendations are in Chapter 4).

- The Bad news: it’s not simple figuring those out, and trying one out is often the only really safe way to confirm eventually. Will do my best to explain it in this article.

Before theory, here is my practical demonstration of the problem and how the screwdriver shown above solves it:

The rest of this post is a rather detailed explanation of the crossed-head screwdriver topic, but with no final answer for now, just a few practical examples.

Took me a lot of time to figure this out and get all the data. Yet, take this article as: “to the best of my knowledge”. Any additions or corrections are welcome.

2. Screwdriver development heroes

“Not all the heroes wear capes” 🙂

– BikeGremlin shower thoughts

Starting with a bit of history. Just as little as necessary to understand the current chaos with cross-head screwdrivers. Don’t be afraid – it won’t hurt. 🙂

Standards, specifications and dimensions are discussed in the 3rd chapter.

2.1. Phillips screwdrivers

You might have heard of these, they are also known as “cross-recess”, “cross-head”, or “cross-point”. How did they come to be, and what is the main problem with them?

A man named John P. Thompson invented (and patented under US Pat. No. #1,908,080) a “recessed cruciform screw” in 1932. In 1933 he also patent-protected a matching screwdriver. But he was probably as good a salesman and capitalist as I am, so he couldn’t get anyone to produce screws and screwdrivers with this patent. 🙂

Then came Henry F. Phillips, who bought the design/patent in 1935 and refined it (the final version patent being US. #2,046,840). A year before that, he had started the “Phillips Screw Company” ( 🙂 ). He understood the advantage of this patent:

Unlike slotted screws of the time, Phillips allowed one to quickly place a screwdriver in the screw – with the screwdriver automatically sliding in place and self-centring. We might take that for granted today, but at the time, it was revolutionary. Just try using a battery-powered screwdriver on a slotted head screw (with a flat-blade tip) to see what I mean.

What are the problems with Phillips?

- Inefficient ways of manufacturing such complicated screws and bits – for the 30s of the XX century. This problem was overcome by the “American Screw Company of Providence”, Rhode Island, and after that, Phillips became widely used.

- Just as easily as a Phillips screwdriver engages with a screw, it also easily disengages. I’ll explain the implications of this in the next paragraph.

Production lines in the 30s (XX century), especially in the growing automobile industry, did have electric screwdrivers, but very few of those had the option of setting up the tightening torque. The Phillips design allowed such screwdrivers to cam out before exerting too much tightening torque on the screw (and damaging the material, or the screw). The problem with this, that no mass-producing capitalist would care about, is when such assemblies need to be disassembled and serviced – as anyone dealing with stuck, rusted Phillips screws can attest.

Many people claim that the easy cam-out was designed on purpose to prevent over-tightening. I couldn’t find any evidence to support that – only evidence supporting the self-centring easy slide-in function could be found.

This leads us to another story – Japan: small country, small people, small machines, yet they are the best! 🙂

2.2. JIS (Japanese Industrial Standard) screwdrivers

“Everything done hastily has to be done again – slowly”

– My late father, Živojin Novović, quite a competent engineer

Samurai have correctly concluded that while screwdriver self-alignment is a great thing, saving split-seconds while inserting it is not worth the headaches with easy cam-out and problems with later disassembling/servicing. So in 1958, they made a very similar design, but with “sharper edges,” to put it that way.

Differences between JIS and Phillips screws and screwdrivers are difficult to tell with the naked eye, but are easily noticed when using a screwdriver!

JIS screwdriver holds well both JIS and Phillips screws.

While a Phillips screwdriver easily slips out of Phillips screws and does even worse with JIS screws.

Read again, and memorize the two sentences above. That is the essence of the problem’s solution. I’ll repeat it with different wording:

JIS screwdrivers work better with both JIS and Phillips screws!

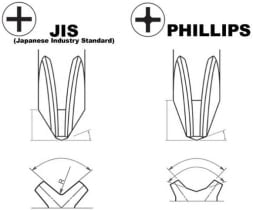

2.3. The difference between Phillips and JIS screwdrivers

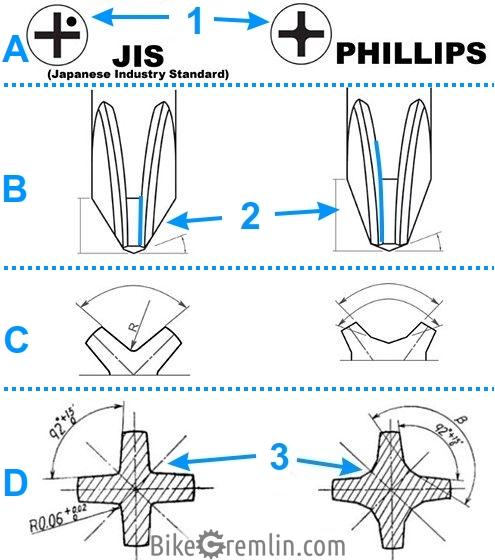

Before a more detailed story about the standards, I’ll briefly explain the main differences. Starting with a picture:

Picture 2

(A) in the picture above shows the difference in the way screws are marked, though not all the JIS screws are marked with such a dot (1).

(B) shows how Phillips has a very slight curve (2) – not really visible to the naked eye (exaggerated in the drawing), but it makes the difference when force is applied, “helping” the screwdriver slip out (and in).

(C) and (D) show tip cross-section when looking straight at the tip. Philips has a slightly larger radius (3), which prevents it from fitting properly into JIS screws.

I’ll repeat: these differences are difficult to spot with the naked eye – all those screwdrivers look pretty much the same.

3. Standards of popular cross-tipped screwdrivers

Now I’ll list the most widely used types, first the obsolete, then the current standard ones, sorted chronologically, so it can be understood more easily.

3.1. Phillips – US standard

Already mentioned in Chapter 2.1, where all its pros and cons are explained.

- It is noted by the letters “PH”,

- followed by a size-code: #0000, #000, #00, #0 (very small, jeweler-sized ones), #1, #2, #3, and #4 (super large, for heavy machinery).

Picture 3

- From 1961 to 2006, it was defined by German standard DIN 5260-2, when the ISO standard superseded it.

- Now it is defined only by (DIN) ISO 8764-1 PH (standard designated in 2004) and (DIN) ISO 8764-2 PH.

(Not very) fun fact: DIN stands for “Deutsches Institut fur Normung” (German Institute for Standardization).

Brief reminder: slips relatively easily out of even the matching Phillips screws, while it’s even worse with the others (JIS and Pozidriv). Phillips screwdrivers suck – plain and simple.

3.2. JIS – Japanese standard

Its history is explained in Chapter 2.2.

It used to be defined by the Japanese JIS B 4633, but in 2008 that standard was declared obsolete, and now it is only defined by ISO 8764-1 PH, and ISO 8764-2 PH. Yes, the same ones used for Phillips screwdrivers! See now where all the confusion comes from? They used to be marked like this, differently:

Picture 4

Update, June 2023:

Klaus shared some interesting information and links in his comments on this article (Klaus’ comments on JIS). Based on that info, JIS has not been made obsolete, but most screwdriver manufacturers have stopped marking their tools using JIS and started marking their tools using ISO and DIN standards – i.e. the screwdrivers are marked as Phillips.

As I explained in previous chapters, JIS screwdrivers are just better in practically every way compared to Phillips screwdrivers. But how to buy a JIS screwdriver when they are noted the same as Phillips ones? Are they all the same now?

The answer to the second question is: “No, they are not the same”. What about the first question? That’s a bit more difficult. I’ll try my best to answer it, but first, a short note on a standard (two, in fact) that often gets confused with the above-noted standards:

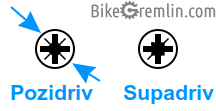

3.3. Pozidriv and Supadriv

Often gets confused with Phillips, at least in Serbia, so it’s worth mentioning. Pozidriv is a European attempt to solve the cam-out problem of Phillips screwdrivers (and screws), patented in 1962 by a British company “GKN Screws and Fasteners”. Later perfected to the Supadriv standard.

- Both Pozidriv and Supadriv are noted by the letters “PZ”,

- followed by a size-code: #0, #1, #2, #3, #4, and #5.

The only difference is that Pozidriv’s “icon” (to call it that) has two more identification “ticks”:

Picture 5

Pozidriv screwdriver will fit any Supadrive screw and vice-versa. However, the Supadriv screwdriver, when used with a Supadriv screw, allows for using the screwdriver at a (slight) angle without risking it coming out when higher torque is applied.

On the other hand: no other screwdriver will fit Pozidriv/Supadriv screws – it will slip out and damage them. So pay attention when you come across these types of screws, and use appropriate screwdrivers:

Note the small lines on the Pozidriv screws between the large cross-flats – that’s how they are easily recognized

Picture 6

Picture 7

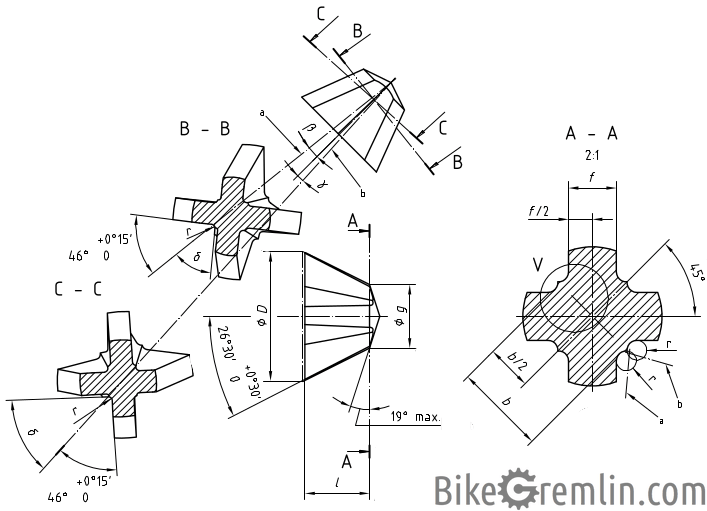

A technical drawing of the Pozidriv standard screwdriver tip:

Picture 8

On paper, it differs a lot from Phillips, but in real life, people often confuse the two – which results in damaged screws that can no longer be unscrewed even using a matching screwdriver.

3.4. Summary – what you can mix with what

To briefly summarize, at the cost of being repetitive, here’s a list of combinations that work well together (other combinations should be avoided):

- Phillips screws: use JIS (preferably, they’ll work better) or Phillips screwdrivers.

- JIS screws: use JIS screwdrivers. Phillips screwdrivers won’t fit very well, so use them with great caution (avoid using them if possible).

- Pozidriv screws: use Pozidriv (preferably) or Supadriv screwdrivers.

- Supadriv screws: use Supadriv (preferably) or Pozidriv screwdrivers.

4. How can I find a good Phillips/JIS screwdriver?

After a brief Pozidriv/Supadriv digression, how does one find a good screwdriver for Phillips and/or JIS screws? In Chapter 3.2. I explained how JIS was discontinued as a standard in 2008, so now there is only ISO 8764. In other words: almost no manufacturers today make and sell screwdrivers noted as “JIS”, only “Phillips, ISO 8764-1, 2”. Some might (also) mention “DIN 5260-PH”, but no “JIS”.

Then how can you tell if a Phillips is one that works well with JIS screws and doesn’t easily slip out of Phillips screws?

It still boils down to trial and error. I intend to run this article with local tool companies and suppliers to see if they have a more universal solution. Until then, I can only recommend what I have personally tested and a few other ones recommended by many mechanics (but I haven’t tested personally):

I use this one – it’s my favourite cross-tip screwdriver; both the handle and the tip are awesome 🙂

Picture 9

Amazon affiliate link – I haven’t tested this model

Update 2023:

I got a set of these screwdrivers. They are good.

The tips are no worse (nor better) than the above-shown Wera, but for my hands, the Wera’s handle fits better, especially when I need to apply more torque for more than a few turns. I love the serrated blade, though – for easier fast spinning when the screw is loose 🙂

Picture 10

Vessel also makes “manual impact” JIS screwdrivers for really stuck bolts (Amazon affiliate link):

Picture 11

While I haven’t tested the above-shown Vessel impact screwdriver, I love the below-shown set by Wera. It’s an impact screwdriver that can be “locked” to work as a striking screwdriver (my video explaining screwdriver types). All the “PH” bits work very well with screws on Japanese motorcycles and bicycle parts (though it’s 25 Nm of torque on impact, so not for the heavy-duty automobile stuff).

Picture 12

5. Sources

- Wikipedia page on screwdriver standards

- Vessel screwdriver manufacturer’s PDF presentation

- ISO 8764-1 standard preview – pdf

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/phillips-jis-and-pozidriv-screwdrivers-explained-article-comments.126/

Last updated:

Originally published:

very interesting clarification of a confusing subject. Thanks for that. Plus I’m a fan of Wera tools so a good excuse to get more 🙂

And instead of this, they try to teach us integers and factorials in middle school… How about knowledge you not might but WILL use in real, everyday life?

Simple solution – buy only good quality tools. Brands that are renowned for quality usually follow stricter tolerances. Wera, Wiha, Proxxon, to name a few. Cheaper tools are not only more loose, but also offer worse material that leads to quicker deterioration of tip geometry which in turn damages any screw this tip engages. Same applies for other kinds of equipment, like wrenches. Really cheap ones seems to be made according to “image from the web” – they look like proper one, but that’s where similarities ends…

It also boils down to one – never-ending War of Formats, on every single thing…

Agree. Would just add two things:

1)

Cheaper tools also don’t fit very well in one’s hand, often being more impractical to use, making the work slower, and less comfortable.

2)

Mathematics is a very powerful, universal tool. And it can not easily be “learned on the fly”. For example: skipping any area makes it next to impossible to understand the more complex stuff that leans on that.

You never know when it might become needed. It’s definitely important for physics, and mechanical engineering.

To be more philosophical: like the difference between giving a man a fish (thus feeding him for one day), and teaching him to fish (thus enabling him to feed himself forever).

So too the schools should teach (young) people to think critically, analyze, draw conclusions, and have some basic knowledge about the world around them.

For this last thing: mathematics is an important tool for understanding the world – it is used in physics, mechanics, even chemistry. Spoke length calculators. 🙂

I never said mathematic is not important. However, higher mathematic is not useful in normal, everyday life of a typical Joe, unless he is nuclear physicist :), while knowledge how to use basic tools is. Give me one example of everyday use of factorials, please 😉

Not everyone will go to college and one can live happily not knowing who Socrates was 😉 Nowadays, education system is failure nevertheless, one example being Flat Earth society. If there is adult person after years of school who still believe that Earth is flat and sky is concrete dome, somewhere something went horribly wrong…

Yesterday on Youtube I saw a guy pouring gas to plastic grocery bag. When it started leaking, he put it in braided basket. While I don’t know if he knows anything about ancient Greece, I know for sure he is idiot who shouldn’t be allowed to roam freely. That is why we have to teach useful things first 😉

Imagining the fuel scene – laughing hard. 🙂

If teaching the practical stuff excludes teaching the other things – it’s a tough choice.

I agree that high math is not very useful for a vast majority of people.

A problem I see (and why I’m not 100% certain):

For those who wish to go on to a university, it helps a lot. Giving them a sort of a preparation, to make things easier later on.

I’m not an expert on education, so could be wrong – maybe such things should not be taught before university, because most people don’t go to a university.

But for those that do – even economics, or some social studies, still use statistics a lot.

It’s difficult to know what one will need in the future.

– Fortunately, I don’t get to choose how our educational system is set up. One worry (tough choice) less. 🙂

If it were up to me – I’d dismiss all the grades for a start, and try to figure out what each particular kid is best at, most inclined to.

A brief digression:

In Yugoslavia, in elementary school, we had classes where we were taught how to build, and repair stuff (including the basics of wood, and metal working). Called “The basics of technical education”.

A bit more on the cycling topic (and a further – digression of the digression 🙂 ) – I remember using bicycle gearing analogy to explain to my class-mates how automobile transmission works, and why it is important. For me it was a revelation of how important and useful good analogies can be for explaining stuff.

We also had lessons called “domestication” (to translate it as such), that taught how to prepare food, how to do basic house work, knit, sew and stitch, how to keep hygiene etc.

So, our secondary (high) schools perhaps had an easier task – factorials, calculus etc. 🙂

However – and here I agree with you 100% – the main use of our rather “thorough” education system is being able to solve crossword puzzles surprisingly quickly. Not much else. 🙂

Guys – there is no such thing as a flat head screwdriver. It is a flat BLADE screwdriver. A flat head screw is flat on the top, with a taper on the underside. It is designed to go into a countersunk hole, so it sits flush with the top surface. Flat head screws can have philips, hex, or slot drives.

https://en.wikipedia.org/wiki/List_of_screw_drives

As far as screwdrivers, I have mostly used SnapOn tools, as well as Wera and Wiha – all top stuff, and I was very happy – until I bought a Vessel ball head screwdriver. They are by far the best drivers I’ve used. Now I discovered their Megadora 980 Impacta – an impact driver. I am now seriously thinking of replacing all my drivers with Vessel. I suggest you buy just 1 and see how good they are. I’m not connected with the company, I just like good tools and hate to strip screws. Yeah, they work great on philips screws, too.

Thank you for the correction (not a native speaker), and the feedback.

Appreciate both very much. 🙂

Hi Relja,

Thanks for posting a very informative article on the “cross point screws” and the various screwdrivers along with your recommendations.

For working on my bikes fitted with Japanese (Shimano) components, I have successfully use the Vessel JIS screwdrivers mentioned in your article. Based on my experience, I ‘m confident the cross-point screws used on Shimano components have a JIS standard cross-point head. A standard phillips screwdriver does not properly engage the cross-point head on JIS standard cross-point screw heads.

Take Care

Small note, I see you recommend the Wera Rostfrei screwdriver. While Wera does indeed make really nice, good quality screwdrivers (however no longer German made… Wiha still makes their stuff in Germany tho)

I would opt for the standard green Wera screwdriver, its blade is not made of stainless steel. But regular toolsteel, wich is a lot tougher. So It will last longer, also its cheaper and they offer a much larger range of fasteners in that line 🙂

These Stainless screwdrivers are made to avoid surface corrosion on stainless bolts and parts. So mainly useful for food, chemcal and medical machinery.

Or if you just want a more corrosion resistant screwdriver, you can also opt for the stainless one 😂 We use the regular ones and they are indeed good screwdrivers. No issues with rust or anything on these as we keep em in a toolbox in the basement.

Other good brands are Facom, wich is French and if you don’t mind selling a kidney you can go for PB Swisstools, they make their tools in Switzerland and boy are they good! Excellent gear, but expensive. A hex set is 3x the price of a Wera one. So unless you use them often its not worth it.

Greetings from Belgium!

Hello,

Thanks for the very good and knowledgeable feedback.

I agree with everything you said. I wrote something similar in the reply to a comment on my video about these screwdrivers (see the first, pinned comment and my reply). 🙂

As explained there, I decided to recommend a tool I’ve personally used and been happy with. The green ones aren’t available in my country – I’ve had lots of problems finding even the stainless steel one.

Facom hex (allen) wrenches are top class. I haven’t tried their cross-tip screwdrivers. Never mind paying more for good tools, it’s usually cheaper in the long run. But I don’t have a lot of choices when shopping for tools. Local stores aren’t well-stocked while ordering online from abroad costs roughly double the price, because of our import taxes and taxes in general.

Relja

i never use single screwdrivers any more as they stopped making the worlds best ones years ago,i am not saying all screwdrivers are bad today but the metal quality on them has gone down abit,i buy loose chromoly screwdriver bits that fit into a magnetic handle,buy one small box of these ones from you local hardware store and you will get all the screwdrivers in one small packet,some of these screwdriver bits can also be used with an impact driver,you can even buy a box of hex sets like this and even security bits that take apart electronic stuff,for about $40 you can buy all you need at once,the other good thing about these loose bits is you can buy very long handles for them as well

you can buy ratcheting magnetic handles for these loose screwdriver bits,a ratchet screwdriver makes work alot more easy especially if you need to do lots,most of these handles also have wider handles so you can control things better and you can use alot more force if needed.

Hi Mike,

Could you recommend a model for a ratcheting screwdriver?

I’ve had very poor results (poor durability) with Bosch, and a few others (can’t remember the brands).

They have been super-practical while they worked.

Relja

if you ever come across a very stuck bolt or screw,method 1=wd40 and hit it hard with an impact driver,method2=drill a small hole in the screw or bolt and try a gadget called an easyout bit,method3= heat the part up with a blow torch if possible then take it out,method4= hit the bolt hard with small cold chizel and hammer,if none of these methods work its time to invent another method

i got a sidchrome ratchet screwdriver a few years back and this one has been very good Relja but like everything they keep changing the quality of products its more or less like everything else now buy a few and try a few.if i was buying another one i would look at sidchrome or repco or kincrome in australia these are reliable brands but many companies do make them,once you find a good one you will never like using just a single screwdriver again,these rachet ones are very good.stanley is another brand,get one that atleast comes with a warranty then if its no good take it back,we have good hardware stores over here if we have a problem they replace any tool no questions asked.

just another little tip,buy some longer screwdriver bits as well as these ones will also fit into a drill even though most have hex ends and you can wind the torque up on a portable drill to get tough screws or hex fittings out

Thanks for this information. I found it very interesting and informative. I’m surprised no one responded about square drive fasteners. It is a vastly simpler format and virtually eliminates camming. It has been around at least 40 years (probably longer), but has never caught on and I’ve never understood why. Thanks again.

Thanks for the VERY informative article. You find those JIS screws all over older Sony/Panasonic VTR (video tape recorders).

BTW, I found that McMaster-Carr lists JIS/JCIS Bit Sets and Screwdrivers on their site. I haven’t ordered from them but I’m tempted to just to see what brand that they actually are. McMaster doesn’t tell you the brand but it it typically good stuff. At least that’s my experience from ordering other tools and fittings from them in the past.

I don’t doubt what you are saying, but I took a look at the sources you cited, and I didn’t see anywhere that clearly states that ISO 8764-1 /2 PH:

1) Is commonly known as “Phillips” and that (presumably) “Phillips”-labeled drivers/bits made today usually comply with it and not with the older original Phillips standard

2) Includes/supersedes/obviates/replaces the “JIS” standard (or the “Phillips” one, for that matter)

3) Is physically compatible and designed to work with both legacy/traditional Phillips and legacy/traditional JIS fasteners

Do you know of an official statement/document (other than the non-free ISO 8764 itself) from a standards body, well-known manufacturer of drivers/bits, or other reputable third-party that corroborates these facts?

Hi Chris,

Thank you for the feedback and please share the links if you find sources that satisfy your criteria, or manage to get satisfactory official feedback from a tool manufacturer.

I tried consulting local Unior representatives (mechanical engineers) and they were clueless about this problem. I also consulted with a company that sells tools of several different brands to other companies – mechanical engineers there didn’t know the answers. Apart from that, I didn’t find any other tool brand representatives willing to talk in my city or country.

What I do know, from practice, is that most “Phillips” screwdrivers, even when brand new, slip relatively easily out of cross-headed screws on my Yamaha and on Shimano derailleurs, while very few screwdrivers don’t. At the same time, the screwdrivers that work well with JIS screws (Shimano and Japanese motorcycles in particular), don’t slip any easier out of Phillips screws (as far as I could tell – they work better with those too).

This also aligns with the feedback I got from other mechanics.

I put all the knowledge and experience that I have so far into this article (and made the brief video demonstration of the problem). Nothing more, nothing less. When I learn new things and get new information, I update my articles.

Since topic is still alive, please allow me to mention here Youtuber Project Farm (https://youtube.com/c/ProjectFarm). He tests various tools (screwdrivers too), compares brands with different price tag, and does that in “real job” testing environment. That way we can also get an idea about tools and brands quality.

Very useful article. I have been aware for long enouigh of the Phillips/Posidrive devide but not of JIS – still learning at 80!

Some 25 years ago I was working in a technical collge in Lesotho. When the joinery department tried to switch from slot-head to ‘cross-head’ screws they were not impressed. I found that in Lesotho and South Africa ALL cross-point scrwdrivrs were Phillips and ALL cross-point wood screws were Posidrive! Joinry reverted to slotted screws until I arranged to import some posi drivers. I hope things have improved now!

I’ve used vessel screw drivers for 20+ years, they compare to snap-on for quality.

Being a certified ASE auto mechanic since 1981. I can tell of a learned experience from an elder much older. When stuck with a ruined or loose fitting phillips screw fill the hole with valve grinding compound then insert phillips screwdriver. Something never taught in school, you can’t ever beat street smarts… if you can find someone willing to share!! You’re Welcome!! 😀

That’s brilliant – thanks, Michael. 🙂

It’s not the first, and probably not the last time I learn something new from an “old hook” as is the local saying.

Sure, theoretical knowledge can help understand why it works, or how to further improvise on it, but I’d never have thought of that myself!

Wrote a whole article on that general topic, titled Theory vs practice. 🙂

Relja

There is no evidence on the worldwide web that the Japanese Industrial Standard JIS was made obsolete in 2008.

It still exists:

https://www.cipa.jp/std/documents/download_e.html?CIPA_AD-001-Translation-2020

Hi Klaus,

Thank you for sharing that informative document.

What still confuses me is that I can not find screwdrivers labeled as “JIS.”

I even got some Japanese ones by Vessel, and they too are marked as P1, and P2 (depending on the size). Vera bits and screwdrivers are marked the same way (P, Phillips). Both those brands fit wonderfully into JIS screws on Shimano and Yamaha. Unior P screwdrivers, on the other hand, don’t fit nearly as well – the same goes for most other brands and models I’ve tried.

Vessel’s website hasn’t got any official explanation now, though if you look at the source code (not visible on the front page itself), it says this:

“Screwdrivers. Why VESSEL\’s screwdrivers are not labeled “JIS”? As you might know, VESSEL is the oldest screwdriver manufacturer in Read more”

The source code link:

view-source:https://www.vesseltools.com/handtools/screwdrivers

Should display the code of the page:

https://www.vesseltools.com/handtools/screwdrivers

It’s fair to note that Vessel’s website does show “JIS” label on the pages that list their screwdrivers. But most other manufacturers don’t display JIS anywhere (Vera, Wiha, and even Japanese Hozan, to name a few I looked into in great detail).

Relja

Hi Relja

you can find more details here:

https://www.pentaxforums.com/forums/attachments/53-pentax-dslr-camera-articles/606492d1686662907-little-bit-history-jcis-jis-ph-screws-screwdrivers-about-vessel-about-jis-jcis.pdf

and here:

https://www.vesseltools.com/handtools/screwdrivers/what-is-jis

I forgot:

Vessel does name their JIS and JCIS screwdrivers P!

Because they don’t pay for JIS certification anymore but only ISO.

This is explained in the download

Hi Klaus,

Thank you very much for the links and the info. 🙂

I’ll update the articles (this one, in English, and the one in my native) to reflect this new info.

Though I think the basic point of the article is still valid as it is:

Some cross-tip screwdrivers work well with the “Japanese screws,” while others don’t.

Most manufacturers mark their screwdrivers as “Phillips” (no JIS standard offically).

It boils down to trial and error and figuring out which ones work well in practice.

So far, I can confirm that Wera and Vessel are great. As well as the small bit sets by Ifixit (4 mm bits), that often come with JIS and Phillips bit types (different, and differently marked). In fact, that’s the only screwdriver (well, bit, technically) that I could find to be actually marked as JIS.

Relja

Once again: JIS was never made obsolete in 2008, the very opposite is the case:

https://en.wikipedia.org/wiki/Japanese_Industrial_Standards

JIS was extended/refined and got a new Logo.

What was made obsolete in 2008 was the dot on screws!

My understanding is that the ISO 8764 standard tries to unify the Phillips and JIS drivers into one universal driver that is supposed to work equally well with both types of screws. It does, but better for Phillips and a worse for JIS. The whole situation with cross head screws seems to be a huge trash fire.