In this post I’ll explain the hub dimensions important (relevant) for calculating the optimal spoke length for building bicycle wheels. A separate post explains important rim dimensions.

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

Table Of Contents (T.O.C.):

- Important hub dimensions

- How to measure the important hub dimensions?

2.1. Measuring spoke hole circle diameter (A and B)

2.2. Measuring flange distance from the hub’s centre (C and D)

2.3. Measuring flange spoke hole diameter (S) - Calculating the optimal spoke length

1. Important hub dimensions

A few pictures (of not the highest quality) will show what is important. Later, we will explain each point, so it all falls nicely into place by the end.

Hub manufacturers often provide these dimensions, but they are not always noted in the same way, and for me it is faster/easier to measure it, than to search the manufacturer websites and figure out what’s what.

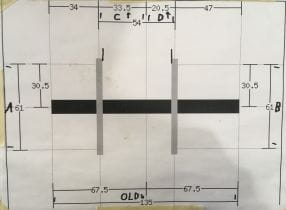

Picture 1

Apart from the number of spokes, we are only interested in A, B, C, D and S – the rest are just the tools to get the ones we want. What is what? 🙂

- A is the diameter of the circle along which spoke hole (centres) are placed on the left hub flange.

- B is the same, but for the right hub flange – left and right flanges often have different diameters.

- C is the distance of the left hub flange from the hub’s centre – compared to the left and right ends, where the hub is placed against the wheel dropouts (see OLD).

- D – the same thing, but for the right hand side flange.

- S is the diameter of the spoke holes in the hub’s flanges – they are practically always the same for each spoke hole in a hub.

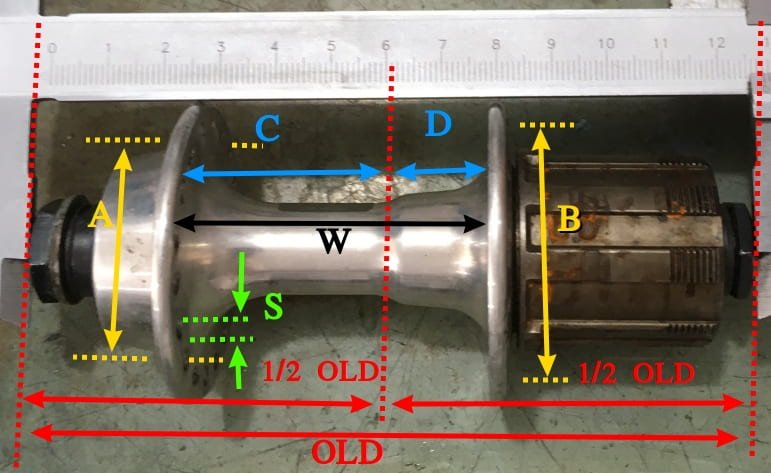

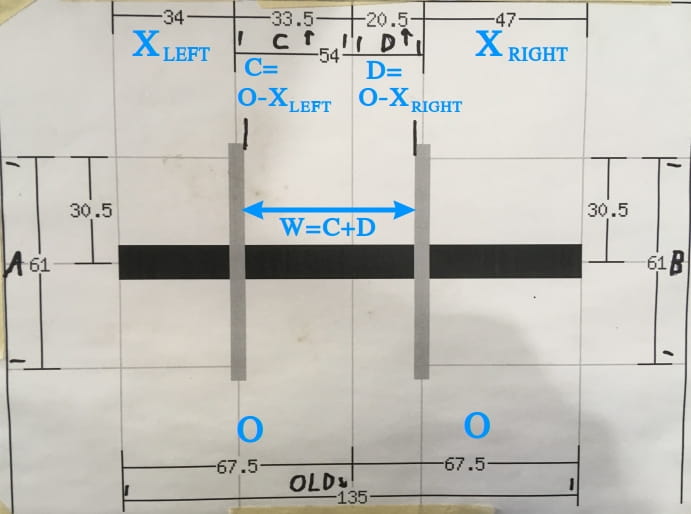

Before we explain how all of this is measured, let’s show a diagram that depicts it better (taken from my workshop):

Picture 2

2. How to measure the important hub dimensions?

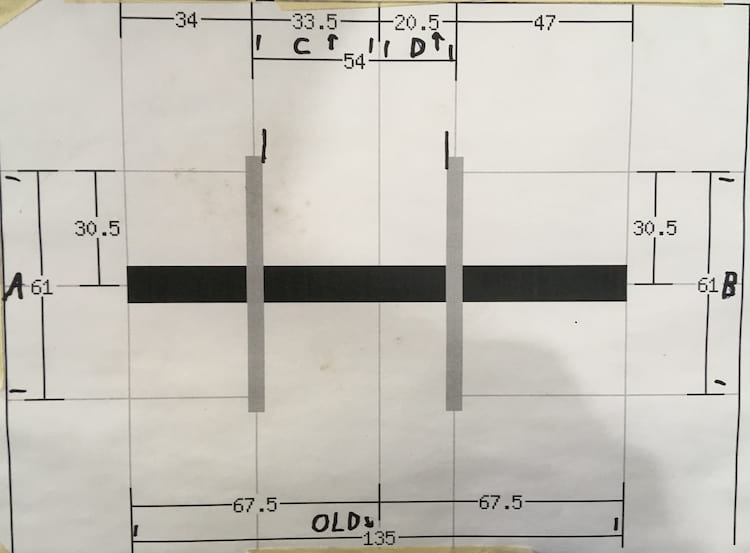

2.1. Measuring spoke hole circle diameter (A and B)

This is easiest done using spring dividers (Amazon affiliate link).

Picture 3

The other way, using “ordinary” calipers is measuring from the inner spoke hole end, to the outer end of the opposite side hole (since with such calipers it is difficult to pinpoint the hole centres):

Mind the tool alignment – and make sure you are measuring the opposite side holes (count the holes in between to be certain)

Picture 4

This should be done for both the left hub flange (dimension A), and the right flange (dimension B).

2.2. Measuring flange distance from the hub’s centre (C and D)

In order to measure this accurately, we will use a bit of basic mathematics. Starting by measuring hub’s OLD (Over Locknut Distance):

Picture 5

I think that picture 5 requires no additional explanation. Write down the result. For confirmation, most often seen OLD sizes (at least in my workshop) are:

- 91, 96 mm – old/vintage front hubs

- 100 mm – modern front hubs

- 120, 126 mm – old/vintage rear hubs

- 130 mm – modern road bike rear hubs

- 135 mm – modern MTB rear hubs

- 142, 148, 150, 157 mm – modern DH MTB rear hubs

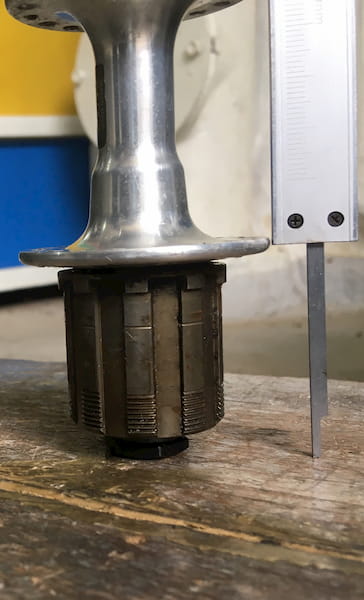

Now we need to measure the flange distance from hub’s end – because that is easy to measure:

Picture 6

I also have a ruler that has marks from its very start – so can be used instead of the calipers as shown in picture 6. You could also use a piece of card-board, leaning it against the hub and marking the flange’s “height” using a pen – then measuring the given distance. In both images above, hub’s axle is put inside a hole, so the hub rests against it’s locknuts, which is the distance we need to measure.

Write down what you measured, that will be size X.

Divide OLD by 2 (in half), that will be size O.

Flange distance (either C, or D – depending on which flange we are measuring the X for) from hub’s centre is:

C or D = O – X

Let’s take another look at the picture from the beginning, with this new info added:

Picture 7

Dimension W from picture 7 is easily measured using a ruler, or calipers. We will use it to double check if we have made a mistake. How?

C + D should equal W.

If the result of C + D differs from W by more than half a millimetre, it means we have made a mistake and should measure again.

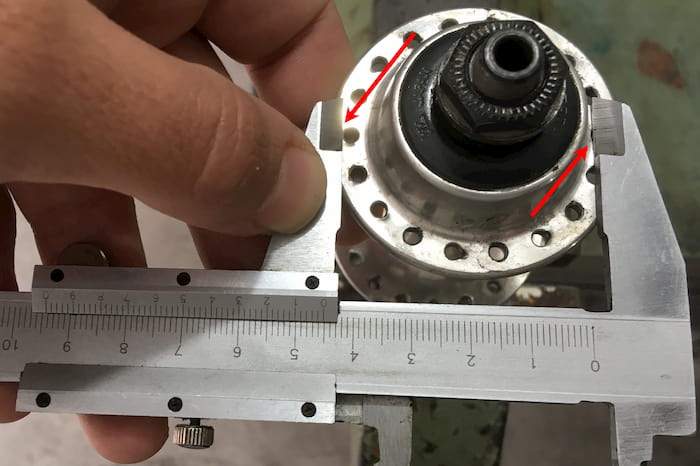

2.3. Measuring flange spoke hole diameter (S)

This dimension is often provided accurately by hub manufacturers. It is usually 2.6 mm. This is how I measure it:

Picture 8

My video explaining and demonstrating how to measure the effective rim diameter (ERD), hub, and calculate the optimal spoke lengths:

3. Calculating the optimal spoke length

To calculate the optimal spoke length, we need to measure the effective rim diameter (ERD). In the 4th chapter of that post, I explained how certain (“exotic”) rim and frame dimensions affect C and D values explained in this post – in terms of determining the optimal spoke length. I suggest you read that post before measuring rim size.

This spoke calculator takes all the above noted dimensions into account, including the effect of the “exotic” rims/frames, so you don’t have to alter the measured C and D values (but this article was written so you can understand the basics, and not depend on any particular tool):

https://www.wheelpro.co.uk/spokecalc/

Calculator use note: I measure X to the middle of the flange, not to its inner part. Since spokes come in 2 mm length increments, rounding the calculated lengths is like this:

- Up to odd numbers are rounded down to the nearest even number (281, 280.9, 280.5 are all rounded to 280).

- Over a whole odd number, round up to the nearest even number (281.1, 281.5, 281.9 – round up to 282).

- Even numbers are rounded (282.2, 282.5, 282.9 – round down to 282).

I would also recommend buying an excellent book that explains all this even better:

Professional Guide to Wheel Building, by Roger Musson (not an affiliate link – I don’t get a penny from the sales). Apart from that book, a great free resource is an article from Sheldon Brown’s website:

Measurements for Spoke Length Calculations

I explained this in a way that I prefer, think it’s best – i.e. the way I would have liked if someone had explained it to me, but the above noted sources are well worth reading.

In a separate post I added the measured A, B, C, D and S dimensions of hubs I worked with (will get updated): hub dimensions for wheel building datasheet.

Help BikeGremlin

stay online & independent

This website is educational, free, objective, and not commercial

(sponsors don’t enjoy paying if you mention all the product downsides that you notice 🙂 ).

How much does a WordPress website cost?

If you find this site to be good and helpful,

and if $5 per month is what you can afford to set aside,

please consider supporting my work with a Patreon donation:

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net