Here, I’ll explain the minimal seatpost insertion length – i.e. the minimum seatpost length that must be inside your frame to be safe (to not damage the frame or the seatpost). In a separate article, I’ve explained seatpost width (diameter) standards.

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

Table Of Contents (T.O.C.):

- Seatpost lengths

- Minimal seatpost length inserted into the seat-tube

- Dangers of not inserting the seatpost deep enough

1. Seatpost lengths

Seatposts are made in lengths from 75 to 430 millimetres. A seatpost can relatively easily be cut shorter, but a too short seatpost can’t be lengthened, of course.

Picture 1

You can adjust saddle height by sliding the seatpost more in or out of the frame (seat tube). Saddle height depends on how high from the pedals the rider wants to sit. I explained that in the Setting up comfortable cycling position article.

Still, when setting up the riding position, be careful not to move the seatpost too much out. That is: keep at least the minimal length of the seatpost inserted into the seat tube. How long is that? I’ll explain in the next chapter.

2. Minimal seatpost length inserted into the seat-tube

Follow the frame and/or seatpost manufacturer recommendations – if they are provided. When giving such recommendations, manufacturers take into the account the strength of the material(s) used, wall thickness, as well as the total seatpost length (which is effectively the length of the lever over which the rider weight puts the load) etc. So their recommendations may be “stricter”, or “less strict” than what is written here below.

Exceptions (when to not follow manufacturer recommendations)? I will give myself the liberty to say that I disregard manufacturer recommendations when they recommend more shallow insertion, than what I advise in this article. To avoid any injury, or equipment damage, I prefer to consciously “err” on the side of caution.

In articles, I usually explicitly note only in case manufacturer recommendations can be disregarded (noting the exact case/situation). In other words: for me it is understood that if not advised otherwise, one should follow the given manufacturer recommendations, when they are available. This is one of the exceptions where I suggest you err to the side of caution.

First safe bet is inserting seatpost at least 150 mm inside the seat tube. This will securely hold on practically any bicycle. See picture 2 below:

Right: Seatpost inserted deep enough (seatpost that is long enough);

Source: www.orangebikes.co.uk

Picture 2

Is it safe to go shorter than that? Sometimes – let me explain:

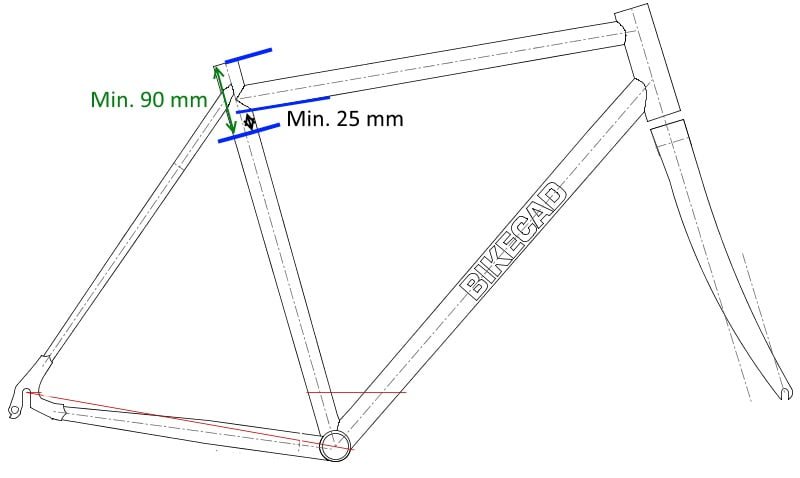

For “men’s” frames, with (more or less) horizontal top tube, minimal insertion depth can be shorter than 150 mm, and is defined by the following two conditions:

a) Seatpost should end at least 25 millimetres below the lower part of the horizontal tube weld/connection to the seat tube.

b) Total inserted length should be at least 90 mm from the top end of the seat tube.

Picture 3 below speaks louder than words:

Source: www.bikecad.ca

Picture 3

Both of these conditions must be fulfilled. If, for example, lowest part of the top tube weld ends 50 mm below the seat tube top, inserting seatpost 25 mm below it won’t fulfill the requirement b) – of minimum 90 mm total insertion depth (seat post would be inserted 50 + 25 mm – so only 75 mm).

The same goes if the lowest part of the weld is at 80 mm for example. Inserting seatpost 90 mm deep would not fulfill the a) requirement of seatpost ending at least 25 mm below the weld. Therefore, seatpost would have to be inserted for total of 105 mm in this case (80 + 25 mm).

Shortening seatposts is very popular with road bikes, for weight reduction. The minimum safe margin was explained in this chapter. What happens if you exceed this? Read the next chapter:

3. Dangers of not inserting the seatpost deep enough

Seatpost not inserted deep enough into the seat tube (as explained in chapter 2.) can cause the following problems:

- It will not stay firmly in place – dropping deeper, or twisting (this is the least of the problems and it happens most rarely, the other problems are more serious).

- Seatpost could bend, or break.

- The top part of the seat tube (the frame) could break.

Most of these problems can be hazardous if they happen when riding at high speeds and/or on bumpy terrain.

Source: www.gripsport.com.au

Picture 4

When inserting a seatpost, always “grease” it with proper mounting paste. For metal seatposts in a metal frame, use an anti seize mounting paste (“copper grease” or similar – Amazon affiliate link). It will prevent seatpost from welding to the frame over time and getting stuck.

Clicking on the link and image below leads to the Amazon on-line shopping. As an Amazon Associate I earn from qualifying purchases.

For carbon seatposts and frames, a special carbon mounting paste should be used:

Clicking on the image opens an Amazon affiliate link with a search for carbon mounting paste

Help BikeGremlin

stay online & independent

This website is educational, free, objective, and not commercial

(sponsors don’t enjoy paying if you mention all the product downsides that you notice 🙂 ).

How much does a WordPress website cost?

If you find this site to be good and helpful,

and if $5 per month is what you can afford to set aside,

please consider supporting my work with a Patreon donation:

Related post – How to choose a correct bicycle frame size:

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

If the frame is made of carbon fiber would 90 mm insertion be enough when the top of the seat stay junction is at 90 mm from the top of the seat tube.

I would feel safer placing the seat tube at least 25 mm (1″) below the lower end of the top-tube – seat-tube junction.

And having it inserted at least 90 mm – both conditions fulfilled.

Safest bet, of course, is following the frame (and seatpost) manufacturers’ recommendations.

Thanks for your advice, feel happier with the amount of insertion I have.

Also please note 25 mm is 1″

Yes, mistake for the 2″.

Update on the 20th of July 2020:

To avoid anyone having any problems, I have added something I had considered to go without saying, but think it should be explicitly noted, to be on the safe side:

Respect the recommendations of the seatpost and/or frame manufacturers, if they are provided. For reasons explained at the start of the (now edited) article’s 2nd chapter.

This improvement/correction, like many others on the website, was made thanks to the good quality feedback: people taking the time to note the things that aren’t explained well enough (or are incorrectly noted).

I find such feedback invaluable and wish to thank everyone who has contributed over the past years – so this can become better and more useful for everyone.

Hi, I have a Cinelli via Folli seatpost and the minimum insertion length marked on it by Cinelli only leaves 70mm in the frame. It feels a very solid seatpost and is made of thick forged aluminium 6061 T6. It’s going to be fitted to a vintage steel road bike frame with a horizontal top tube etc. Reckon that should be ok?

Hi,

Seatpost not inserted deep enough poses a risk to damage either frame, or the seatpost (whichever gives first).

The insertion limit depends on various things, such as:

– Frame design (how high is the point where the top tube is connected to the seat tube).

– Frame material and strength in the seatpost clamping section.

– Seat post strength.

– Rider’s weight.

– Riding terrain (of road, or paved roads).

– Total seat post height.

On a steel road bike, with a horizontal top tube (so connected to the seat tube at a very high point, near the end of the seat tube), where the seatpost is not likely to protrude much (since the frame is designed to match rider’s height, unlike the modern design where they just put the top-tube across, and see where it ends up 🙂 ) – I would expect it to be fine.

With a disclaimer: picture 3 of this article shows the “safe bet.”

Disclaimer 2: cycling industry engineering is not what I’d call good engineering. Over the years, I’ve learned to take it as more of a guideline (and warranty protection) than gospel.

Bottom line: if the frame is not precious (either in terms of cots, or, more importantly, sentimental value), I’d give it a go. If it is – I’d look for a longer seat post, just in case. Colour me conservative. 🙂

Relja.