This post shortly explains important things concerning bicycle rim tape. Many cyclists already know all this, but many don’t – author of the text has often had bicycles brought into his bicycle repair shop with tubes punctured, or damaged from the rim, or the spokes – because of rim tape problems.

If you have any questions (or additions and corrections), please use the BikeGremlin forum (www.bikegremlin.net) – here is the discussion regarding this article:

https://www.bikegremlin.net/threads/bicycle-rim-tape-explained-article-critique.67/

Table Of Contents (T.O.C.):

- What does the bicycle wheel rim tape do?

- Rim tape dimensions

- Rim tape types

- Bicycle wheel rim types

- Tape for tubeless-ready rims

- Optimal rim-tape width (tube, tubeless, and hookless tubeless)

- How to mount rim tape

TL/DR

Here, I answer the questions:

- How to choose a high-quality rim tape, and why that matters?

- How wide should the rim tape be (especially important with tubeless setups)?

- How to properly mount rim tape?

1. What does the bicycle wheel rim tape do?

Rim tape is put directly onto the rim. It’s function is to cover all the sharp and rough edges, therefore protecting the tube from being punctured by the rim. A very simple device. It’s supposed to stick firmly to the rim, preventing tube from being punctured by spoke nipples, or by spoke nipple holes in case of rims with recessed spoke holes.

If you are a fan of tubless bicycle tyres, your rim tape will also need to seal your rims (preventing any air from seeping out) – see section “5. Tape for tubeless-ready rims” for more details.

2. Rim tape dimensions

There are two standard widths (most common, but there are other widths as well). Narrow 15 mm ones, and wide 19 mm.

When it comes to length, they also come in two variants: in self adhesive rolls (like duct tape), that can be cut to the desired rim circumference; or pre cut and glued to a certain rim size standard, with a pre-drilled valve hole.

For example: a MTB wheel will use a rim tape for 559 mm diameter rims (MTB standard) and 19 mm wide; while a road bike with narrow rims and tyres will use a rim tape cut for rims of 622 mm diameter, 15 mm wide (bicycle wheel and tyre sizing standards).

Help BikeGremlin

stay online & independent

This website is educational, free, objective, and not commercial

(sponsors don’t enjoy paying if you mention all the product downsides that you notice 🙂 ).

How much does a WordPress website cost?

If you find this site to be good and helpful,

and if $5 per month is what you can afford to set aside,

please consider supporting my work with a Patreon donation:

3. Rim tape types

There are rubber ones, made of material similar to the one used for tubes. They are quite easy to stretch, which makes them easy to slide onto even bigger rims than the one they are made for – in case of emergency.

The more expensive and of higher quality are tapes made of strong fabric (or hard rubber/plastic). They usually have “high pressure” printed on them.

4. Bicycle wheel rim types

There are simple single wall rims, where spoke nipples are screwed onto the rim interior, so that rim tape goes directly over the spoke nipples:

Rim tape lies directly over the spoke nipples.

For this type of rim, cheap rubber rim tape can be used, or a tailored old tube, or even duct tape.

Note:

If a wheel is built with spokes too long, so they protrude out of the nipples, then you’ll need a very strong and rigid rim tape to prevent the spokes from puncturing the tube.

Modern rims are usually double walled (and made of aluminium).

Nipples are recessed inside the hollow rim, with the rim’s outer edge having (sharp-edged) cutouts for an easy access the nipples

(some double-walled rims have no nipple cutouts and that makes them a big hassle to build a wheel with)

With these rims, tyre pressure presses tube against the sharp holes. That’s why a high quality, high pressure rim tape needs to be used. Rubber rim tape, old tubes, duct tape etc. will not do with these rims.

5. Tape for tubeless-ready rims

Tubeless are the tyres without the (inner) tubes. They require special rims for tubeless tyres, or at least “tubeless-ready” rims. Tubeless-ready rims can be “turned” into tubeless rims by mounting a special sealing rim-tape.

Amazon affiliate link

Such rim tapes have to seal very well, to prevent any air leaking through spoke holes in the rim – because tubeless tyres have no tubes to hold the air.

6. Optimal rim-tape width (tube, tubeless, and hookless tubeless)

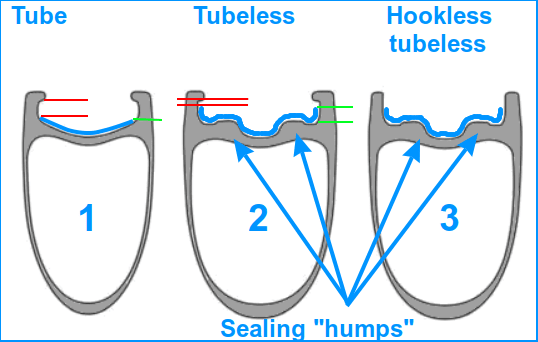

Rim tape should fit the lower, flat rim section completely – from wall to wall. For tubeless ready rims, it should also “climb” up the walls a bit, but not all the way. A drawing explains this better:

So, for tube rims, the rim tape should preferably not “climb” the sidewalls, while for tubeless-ready rims, it should ideally climb for 1 mm, or more, but not all the way, since it will then prevent the tyre from seating correctly.

Note that the rims have a bit curved section where the rim-tape lies, and that the rim-tape gets a bit narrower as it is stretched over the rim.

What exact rim tape width do you need?

First measure the inner rim sidewall width:

Now:

- For tyres with tubes, take rim tape of that width, or up to 2 mm wider, depending on the rim’s shape and how much the rim-tape stretches and narrows in width as it is stretched.

- For tubeless-ready rims with tubeless tyres, take a rim tape that is 3 to 5 mm wider, depending on how much the rim is curved, and how tall the sidewalls are.

Yes – this is a bit of a trial and error. Much depends on how much a rim tape stretches, and narrows in width as it is stretched over the rim, as well as on the rim’s shape. Details are shown in the drawing and explained at the start of this chapter.

7. How to mount rim tape

When mounting a rim tape, there are two things to consider:

- Facing (which side goes towards the rim).

- Mounting procedure.

When it comes to facing, the rules are simple:

- If there is a brand name printed or similar decals, they go on the outside (towards the tube).

- If there is a sticky side, it goes towards the rim.

- Without any of those present, the rough(er) side goes towards the rim, and the smoother side towards the tube.

Now, when it comes to mounting, here are a few tips, followed by a video demonstration:

When mounting rim tape, attention should be paid if it is not too narrow (so it doesn’t slide off nipple holes), or too wide, so it interferes with tyre mounting.

Since it can slide during mounting, a valve can be put through the valve opening on the rim tape and the rim, to hold everything in place – or you can use a 6 mm hex key, a screwdriver, or something similar.

Here’s a video demonstration of how to remove and mount tubes, tyres, and rim tapes – it is divided by sections (shown in the timeline and in the video’s description) so you can skip to the parts of interest:

Author’s recommended rim tape. Clicking on an image below opens Amazon.com on-line shopping search (as an Amazon Associate I earn from qualifying purchases):

Choose the size for your wheels (rims).

If you have any questions (or additions and corrections), please use the BikeGremlin forum (www.bikegremlin.net) – here is the discussion regarding this article:

https://www.bikegremlin.net/threads/bicycle-rim-tape-explained-article-critique.67/

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/bicycle-rim-tape-explained-article-comments.135/

Thanks for the good article! Your links to Amazon at the end of it are missing though.

Thanks for the note.

The original idea was to provide a link for people to conveniently buy decent quality at low price, without need for looking loads of adds, comparing prices. Recommending something I know works well.

However, Amazon offers seem to change, so links work for quite short amount of time often. Can’t manage to update them all, so I’m removing them.

Many thanks, for the very detailed instructions and tips on how to remove and change and reinstall the rim tape, inner tube and type back on the rear derailleur. Your detailed tips are very useful indeed.

the rim tape should be wide enough and thick enough as to ensure that the tire bead presses on the rim seat with some force – depending on the torque generated by braking or pedaling etc. the tire will be pressing on the side walls of the rim but with not so high force as to ensure there is no movement and there’s also tire flex allowing the tire beads to move up and down and not be precisely true to the rim.

the rim’s channel is deeper for rims that are designed for tubeless to make tire mounting easier and also ensure that the tire bead presses on the rim seat. if the rim channel is not deep enough then you either have to work harder when mounting the tire or you can have a compressible rim tape like butyl. i have had good results with laying an additional layer of butyl – cut tube – over a more harder layer that covers the holes.

so, even for a tubed wheel this is advisable. in some cases, not all. there are plenty of tires that are easy to mount but will not stay at fixed positions and there are symptoms, one of them is that the spoke tension remains exactly the same after mounting the tire, inflating them a bit and then lowering (tire) pressure to zero. the spoke tension should be a bit lower. that’s how you know that the tire bead is pressing on the rim seat to some degree. you either want a higher force or are comfortable with a lower one.

the rim can have have it’s diameter shortened as high as 1mm if the builder managed to achieve a high spoke tension that is appropriate with plain gauge spokes and high spoke count. the wheel will be heavier but more durable. high average tension makes the additional tension at dynamic loads to be raised with less delta tension. but it is not advised getting to higher than recommended tension for the rim unless spoke tension variance is low, like +/-5% (having radial runout at +/-0.05mm). if non drive side spokes are not butted but are the same thick spokes as for the DS then the additional tension that occurs at 4:30 and 7:30 positions for the DS will not be as high as for using butted spokes on the NDS (non drive side) which would participate less in holding the wheel together radially (the lever effect).

thinner spokes should be used for being lighter, not so large loads on the rims. at lower average tension that is appropriate for thinner spokes there will be less compression on the rim.

Nice points and nicely explained. 🙂

As far as I know, tyre is held on by the side-walls, not on the part where the rim tape is. All that rim tape needs “to do” in those terms is not interfere with proper tyre seating when it is being mounted and inflated.

Super low pressure tubeless tyres are also similar in those terms, though I have limited experience with them.

For the total aggregate spoke tension, I’d advise to leave some 20 – 30 % “room” – not go with the rim’s max. tension capacity.

I’d agree with the rest.

adi pe: I read your amazing lecture post and I’m so depressed, I thought I was reasonably intelligent and knew a bit about bike mechanics but now I realise I am just pond life!!

I just hope you are the Jedi master of wheel building and this level of knowledge is not normal.

Anyway, as Lance said, it’s not about the bike – I’ll stick some rim tape in and pedal on…

I made a series of videos on bicycle wheel building (in Tarzan English 🙂 ) – with recommended wheel building books in the video description. Think that is good enough to make reasonably durable and reliable wheels:

Wheel Building

Thanks Relja, I had a look – very useful.

My bike tire says 32-622 (28x 1 1/4 x 1 3/4). So what does the 622 stand for? Several websites say 622 mm but that converts to 24 inches, but the diameter really is 28 inches. I don’t get it.

It is explained in this post:

https://bike.bikegremlin.com/285/bicycle-tyre-dimensions/

32 is the tire width.

622 is the rim circumference in millimeters.

the best rim tapes i have ever used for clincher rims are zefal cloth adhesive rim tapes,they never fail,i use size 17mm wide ones on most skinny road bike tires,zefal even make a 13mm wide tape for ultra skninny rims and they make a 22mm wider one for mountain bike rims,these rim tapes last a long time and they can be trusted,rubber rim tapes tend to break and fail as they age.i have seen zefal tape still in place and not damaged on 15 year old rims,they are tough,you can use them on double walled alloy rims or single walled rims.