Most bicycles, except some tubeless models, use tubes in their tyres. Tubes are used to hold the air in, of course, while the (outer) tyre is responsible for firmness and grip with the surface. This post will explain important things concerning bicycle tubes, including: dimensions (sizes), valve types (Schrader, Presta, Dunlop…), valve lengths etc.

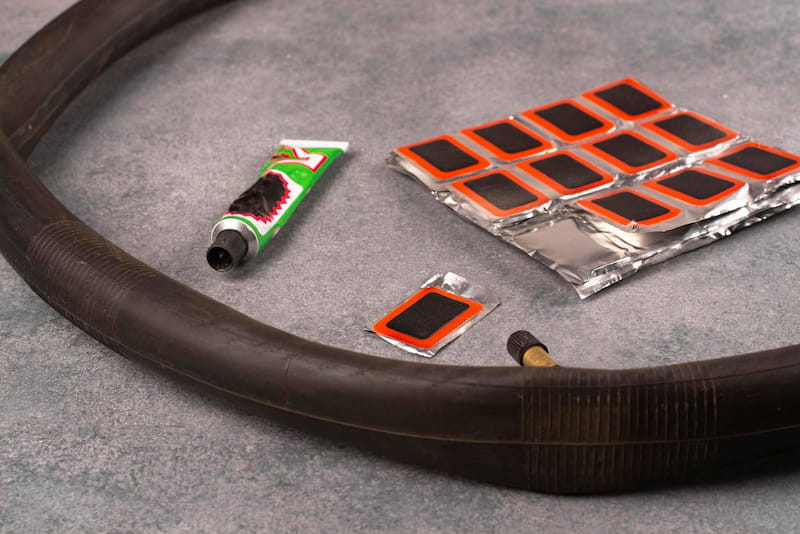

Replacing and repairing punctured tubes:

Patching a punctured tube

Mounting tyres and tubes on wheels

1. Tube and valve quality

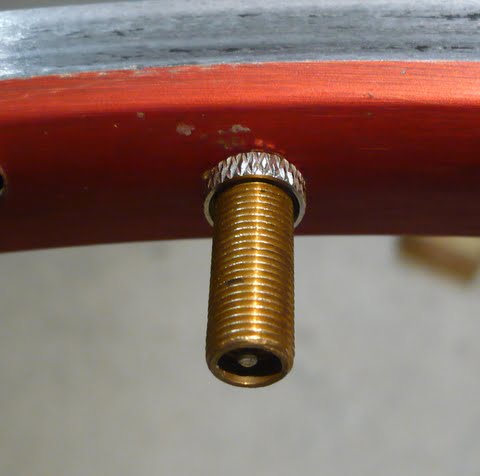

A good quality tube needs to be made of good rubber in order to hold air well. It should also have a good quality valve. The valve itself should have threads to hold a screw that keeps the valve in place, even when the tube is deflated.

The nut prevents the valve from dropping in when the tube is deflated. It, however, should be kept loose, not tightened, since when tightened it tries to rip the valve core from the tube inside (especially as the tube loses pressure over time if it had been tightened after the tube was inflated).

2. Tube sizes (dimensions)

Tubes are rather flexible, so one size of tube fits a wider range of tyres (with a range in tyre width, as well as wheel diameter). Manufacturers usually state which tyre dimensions the tube fits.

(1.5 to 2.10 inches, i.e. 37 to 54 mm),

as well as the rim (and tyre) diameter the tube fits

(26 inches, i.e. 559 mm).

Note that it fits both 622 mm rim diameter tyres, as well as 630 and 635 mm ones,

with the given range of various widths.

Can’t find the matching size tube?

If a proper fit can’t be found it is a rule of thumb that a size smaller is better than a size larger tube (this goes especially for width, less so for diameter). A larger tube will be harder to fit into the tyre and might not stretch properly when inflated. Tyre dimensions are explained in the post: Bicycle tyre sizing and dimension standards.

Just be reasonable. For example, I’ve used 622 – 18 to 28 mm tubes with 32 mm tyres and had no problems. However, using such tubes in 37 mm wide tyres, sometimes resulted in tubes getting split open, especially at higher pressures and loads.

2.1. Valve length

One should also pay attention to valve length. Deep rims require longer tube valves, while thinner rims look awkward with long tube valves sticking out of them.

3. Valve types (standards)

Of all the valve standards, three are still widespread in use: Dunlop, Schrader and Presta valve.

3.1. Dunlop valve

Also known as “Woods” and “English” valve.

This valve is outdated, but still popular in developed countries. Valve width is close to the Schrader valve, so can be used on the same rims. It can be inflated with a Schrader compatible pump if a Schrader adapter is mounted. Schrader adapter is the same for Presta and Dunlop valves.

Valve stem width is about 7.7 mm (important info for clearing the rim’s valve hole, because some rims are made for the narrower, Presta valves).

3.2. Schrader (auto) valve

A commonly used valve, seen on most car tyres, as well as many mountain bicycles. It has a core that is replaceable. It is recommended for most uses, except when a rim is very narrow, so that thin, Presta valve must be used.

Unless there is a specific reason to use thinner valves, tubes with Schrader are probably the most convenient.

Valve stem width is about 7.7 mm (like Dunlop valves).

3.3. Presta valve

closed Presta valve, opened Presta, Presta with a Schrader adapter, Schrader valve.

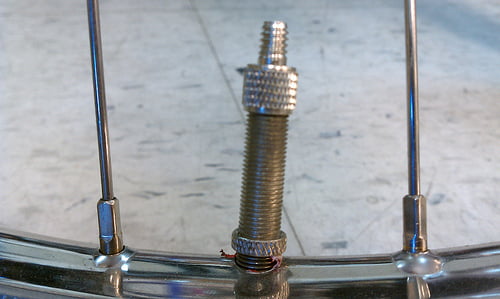

An advantage of the Presta valve is that it doesn’t have a strong spring that a pump needs to overcome. This makes it is easier to inflate. It is also thinner than the other two – convenient for thin racing rims and wheels. Pumps for Presta valves can also be made in smaller dimensions than Schrader pumps.

When inflating Presta valve tubes, a locking nut should be unscrewed by several turns (the picture above shows closed and open Presta valve). Then the valve head should be pressed down once (letting out a bit of air if the tyre isn’t completely flat), to unstick the valve seal for inflation. After inflation, the locknut should be screwed tightly to prevent air leakage.

The core of Presta valves can be replaceable, but they are seldom produced with replaceable cores. Only a few manufacturers (e.g. Schwalbe and Continental) produce Presta with replaceable valve cores. Removable Presta cores can be identified by two wrench flats on the coarse valve cap threads.

Rims have either a wide valve hole for Schrader, or a narrow hole for Presta valves. It is not wise to put a Presta valve tube in a wide hole, and it is not possible to put a Schrader valve tube in a narrow Presta hole. So by choosing a rim, the choice is made for one of the two modern tube valve standards.

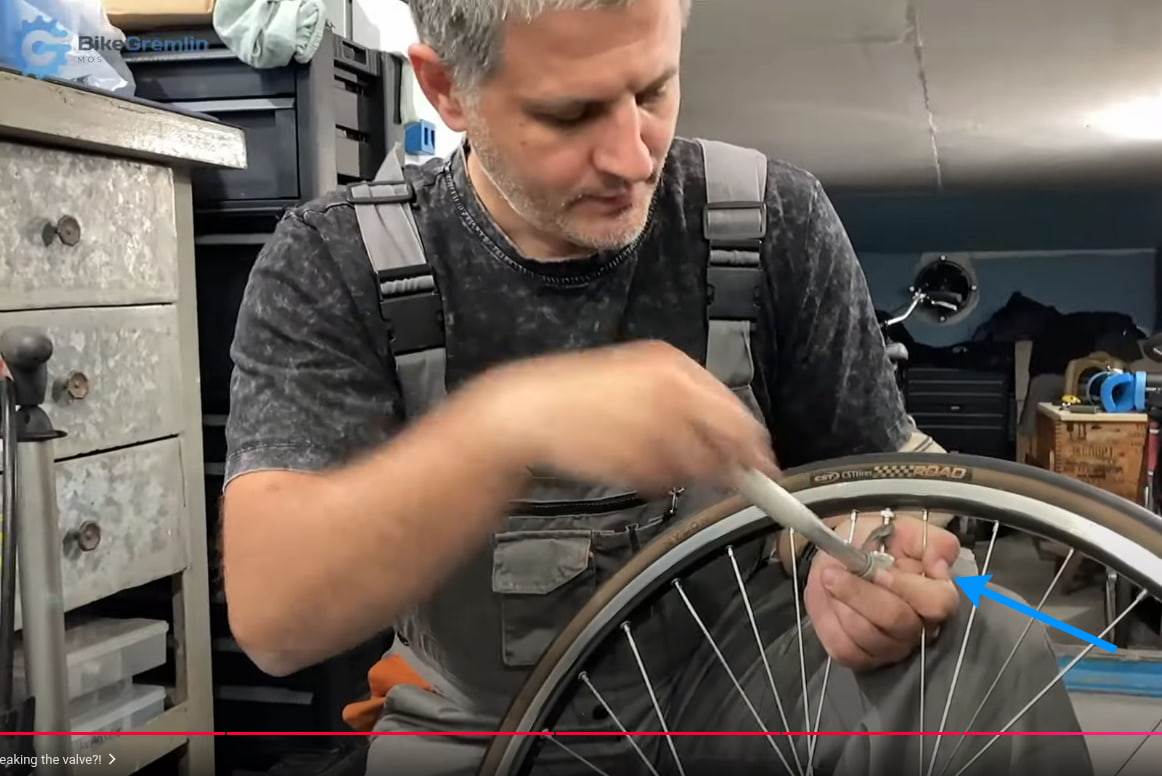

3.3.1. Breaking the valve stem?

Presta valve stem width is about 6 mm.

This makes them prone to breaking unless handled with care! Make sure to not use any sideways force when pumping a presta valve (if your pump doesn’t have a flexible hose, make sure to use your hand and your knee to keep the pump’s head from janking on the valve while you’re pumping).

3.3.2. Drilling the rim for an auto valve?

Some people think it’s a good idea to simply drill a larger hole in the rim and switch to auto valves. If the rim is aluminium, double walled, and wide enough for 35 mm tyres, then this may work well. For the narrow road bicycle rims (and for weaker rims or carbon rims etc.), this may compromise the rim’s strength. So use some caution and common sense.

3.4. Tubeless tyre valve

Tubeless tyres have no tubes to hold the air inside, so the valve is mounted directly onto the rim, and it needs to seal properly, preventing any air from leaking between the valve and the rim.

These valves must have removable cores because sealant needs to be poured in through the valve.

Tubeless tyres need to be inflated very quickly when they are first mounted (and inflated). This is usually done using a compressor, or CO2 cartridge pump. If they are inflated at “regular speed,” the air will slip out between the tyre and the rim, before it is able to push the tyre against the rim and create a seal. Sometimes it is better to remove the valve-core to achieve rapid-enough inflation.

Amazon affiliate link

3.5. Valve types pros and cons

The idea for this section is the great forum question deserving a proper answer. Briefly, the pros and cons of each valve type:

- Dunlop valves

Impractical for quick locking of the pump head – you must either screw on an adapter, or use one hand to hold the hose on the valve. They don’t provide an accurate feedback of the tyre pressure while pumping. I would say they are more prone to air leaking, while not allowing convenient controlled release of air. Unlike Presta valves that can be released by hand, when these stick, you need extra pressure in order to “unstick” the valve seal when inflating. - Schrader (auto) valves

A bit wider and heavier compared to Presta valves. The increased width makes them stronger, while modern bikes don’t use rims (and tyres) so narrow to require the thinner Presta valves. The main disadvantage is that you need to overcome the valve’s spring when inflating. - Presta valves

These valves are the thinnest. If you are using very narrow rims for very narrow tyres, you don’t have much choice. However, today the super-narrow tyres and rims are obsolete even on road bikes. An additional advantage is that you can (and should) use your hand to get them unstuck before pumping, and there is no spring load to overcome when inflating. The main downsides are the more complicated operation (for an average cyclist, this is the most confusing patent), and the fact they easily break (especially if you are using a small frame pump without a flexible hose).

4. Video about bicycle valves

4.1. Video: How to inflate Presta, Dunlop and Schrader valves

Last updated:

Originally published:

I had forgotten the names of tire valves and which one was strictly for road bikes. This web-site gave to me the answers that I needed. Thank you.