This article answers the questions:

Do I really need a torque wrench to service my bicycle?

What kind of torque wrench should I buy?

Table Of Contents (T.O.C.):

- Introduction

- Do you really need a torque wrench (for bicycle mechanics)?

- What to look (out) for when buying a torque wrench

3.1. Torque range

3.2. The intended use - A downside of all the torque wrenches

- Torque wrench buying recommendations

5.1. Small torque wrench

5.2. Medium torque wrench

5.3. Cheap, but good torque wrench

5.4. Solid torque wrenches that aren’t too expensive - Conclusion

1. Introduction

For those who are curious and wish to learn, in a separate article I answered these questions:

- What is tightening torque and why is it important?

- What are torque wrenches and what kinds of them exist?

- How to properly use and take care of your torque wrenches?

The article: “Tightening torque and torque wrenches explained – 101“

In this article, I’ll answer the following questions:

- “Do you really need a torque wrench?”

- “What should you look (out) for when buying a torque wrench?”

- “Which torque wrenches do I recommend?”

I didn’t want to just list a few models (that would have been easier). I think it is better in the long run that I explained the essence first, what to look for and take into account, so whenever you read this you can choose what is best for you, according to your budget and needs.

Yes, brevity is not my virtue, but there is a table of contents at the start of this article, so you can easily “skip” to the parts of interest. 🙂

2. Do you really need a torque wrench (for bicycle mechanics)?

If you ask salesmen, bike(parts) manufacturers or even many cyclists, they will tell you that you must use a torque wrench. My advice is just a little bit different – and quite a bit longer. 🙂

Note/disclaimer:

What I’m writing in this section (2) is my opinion, based on my knowledge and experience.

I already wrote about the “You state your own opinion as a fact” objections, and have nothing to add on that subject.

With a little bit of “feel,” practice and experience (and decent tools), you don’t really need a torque wrench for most stuff on a bicycle (and motorcycle or a car for that matter). What could you do instead of buying a torque wrench?

- Work with decent-quality tools, with care and concentration, prepare all the threads (mounting and anti-seize pastes – what are they and when to use them?), and practice on some cheap parts to get a feel for it. Of course, mistakes are inevitable – you can’t know what’s enough until you see what’s too much. 🙂

- Pay attention to all the connections on your bicycle and note when something becomes loose or starts rattling (that means it was either not tightened with enough torque, or not mounted properly – one needn’t exclude the other).

Unfortunately, it is very difficult to develop the feel for it without making mistakes. Ironically, one of the ways to get a feel for it is to, in fact, use a torque wrench (borrowed one should do fine):

- Clean the threads and smear some mounting paste on them (or grease if you don’t have any mounting paste at hand).

- Tighten a bolt with a torque wrench to the specified torque.

- Loosen it, and use that opportunity to get the feel for how tight it was.

- Re-tighten it without a torque wrench to as close as you can to the specified torque.

- Use a torque wrench to check how much you’ve under or over-torqued it.

To check this, try tightening the bolt using a torque wrench set to the specified torque:

- If the bolt moves a lot – it was way under-torqued.

- If it moves by only about 1/4 of a turn, it was some 10-20% under torqued.

If the bolt doesn’t move, set the torque wrench to a 15% higher torque (don’t do this with expensive superlight parts, especially not carbon):

Once you stop turning a bolt, you’ll often need some 10-15% more torque to get it moving again, compared to the torque you had applied before you stopped. I explained that in a separate article (and video), in the section: “How to use torque wrenches correctly?“

- If the bolt moves before the torque wrench clicks or reaches its set torque, then you got the torque right.

- If the bolt doesn’t move, it means you’ve most probably overtightened it.

In practice, I’ve worked for a decade without a torque wrench and never had any problems. Of course, if you wish to be on the safe side, follow the manufacturers’ instructions and use a torque wrench. The same goes for any super-light parts (whether aluminium or carbon), or when working on other people’s bikes. This leads us to the next section. 🙂

3. What to look (out) for when buying a torque wrench

When buying a torque wrench, it helps if you know the following two things:

- Which torque ranges you will be using it for?

- What kind of work you’ll be doing (and in what kind of environment)?

In this article, I’ll be using bicycle servicing as an example (that is the main topic here after all), but the principle is the same for other use cases. So, why is this information important?

3.1. Torque range

All the torque wrenches have a defined maximum torque they can measure. In practice, torque wrenches are most accurate between of 20% to 90% of their maximum torque (for more details, see torque wrench accuracy and precision).

For example:

- A torque wrench that has a maximum torque of 60 Nm is most accurate (and most precise) in the range of 12 Nm to 54 Nm (20% of 60 Nm is 12 Nm).

- A wrench with a max. torque of 16 Nm is most accurate in the range from 3.2 Nm to 14.4 Nm.

In my experience, most torque wrenches get more difficult to work with once you pass 90% of their maximum torque (especially those that are built to be more compact) – more difficult to set and control the torque delivery.

Hence, in practice, a torque wrench is good for the range of 20% to 90% of its maximum torque. Keep that in mind when shopping.

3.2. The intended use

To explain the importance of considering the intended use case when buying a torque wrench, I’ll start right away with an example:

A wrench for torques over 30 Nm intended for bicycle mechanics use should be able to measure torque in both directions (for left-handed threads too), because pedals and many bottom brackets are screwed in “the wrong way.”

For automobile mechanics, on the other hand, as far as I know, this is not important (unless you work on some lorry trailer wheels).

Another example is a torque wrench for torques below 20 Nm, intended for bicycle mechanics. For that, the reverse direction torque measuring is not important (all the left-handed thread assemblies on a bicycle are torqued to 30 Nm or more). What is important are the compact (small) dimensions, especially the wrench’s head – so you can reach all the “tight spots.” With motorcycle mechanics, on the other hand, I’ve never faced a problem of a torque wrench being too bulky (I’m not saying you’ll never face such problems with motorbikes, it probably depends on the model, but I’m trying to explain the principle).

4. A downside of all the torque wrenches

Torque wrenches need to be re-calibrated on a regular basis – and that costs.

Torque wrench calibration laboratory in Serbia (in Belgrade – if you happen to know of a good one in Novi Sad, please let me know 🙂 ):

https://www.hahn-kolb.rs/sr/hahn_kolb_rs/servis/laboratorija.php

An exception to this are the beam type torque wrenches, where the “needle” pointing the torque can be re-set to zero by slightly “bending” it with your hand. The downside of this type of wrenches is they are the least practical and slowest to work with.

High-quality digital torque wrenches with a tactile feedback last longest in practice before they need recalibration, but they do need batteries and cost an arm and a leg.

Snap-On and Stahlwille electronic (“digital”) torque wrenches are very expensive and of a very high quality.

Cheap digital torque wrenches are rubbish.

I would also add, and this is my impression and opinion (based on my knowledge and experience):

Torque wrenches with a narrower torque range stay calibrated for longer, compared to those with a wider range (all else being equal).

5. Torque wrench buying recommendations

The choice definitely depends on the planned use case. For bicycle mechanics, you can get practically every job done with one “small” (up to 15 Nm) and one “medium” (15 to 50 Nm) range torque wrench.

I haven’t got much experience with large torque wrenches for 100 Nm or higher torques, but I can recommend good small and medium ones. Fair?

5.1. Small torque wrench

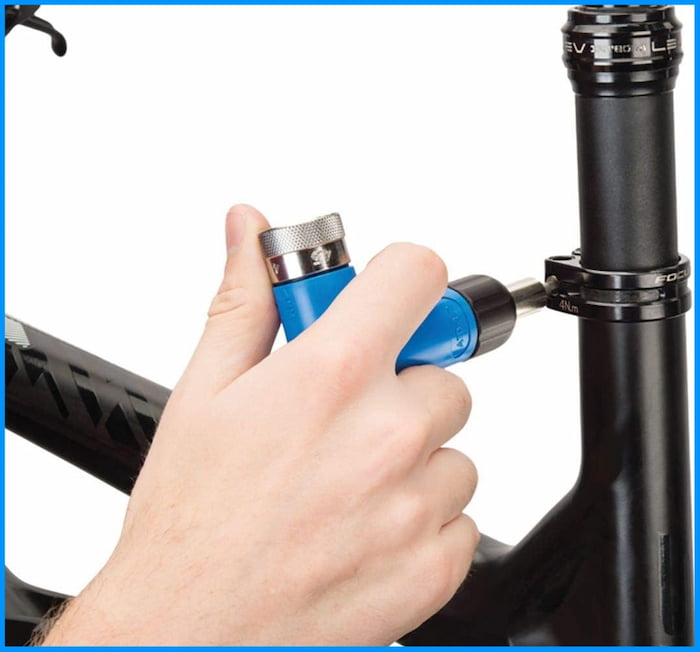

For torques from 2 to 15 Nm, I would recommend the Effetto Mariposa Unisex Giustaforza II torque wrench (Amazon affiliate link).

Characteristics

- An excellent small wrench with a range of 2 Nm to 16 Nm (very accurate in the range of 3 to 14 Nm).

- 1/4″ square ratcheting head (square drive socket wrench size standards).

- Measure torque in both directions (though, in this torque range, there are no bicycle bolts with a left-handed thread).

Advantages

- High-quality (durable and pretty robust for a precision instrument).

- Very accurate (and precise).

- Small, compact size (for a ratcheting head wrench).

- Quick and easy to set to a desired torque (some models need long “winding” to get to the desired setting).

Downsides

- Price, for sure, though it pays off after a generation or two (looks like one of those tools you inherit from your grandfather).

- Small marks for torque settings (which is why I am certain the grandfather will eagerly give it to his grandkids 🙂 ).

This is a wonderful wrench for torques up to 12-13 (even 14) Nm, after which I switch to the next one:

5.2. Medium torque wrench

For torques from 12 to 55 Nm, I’d recommend the Birzman BM18-TW-10-60NM wrench (Amazon affiliate link).

Characteristics

- A solid medium torque wrench (for bicycles I am yet to need anything bigger), with a 10 to 60 Nm torque range (very accurate in the 12 to 55 Nm range).

- The ratcheting head has a 1/2″ square interface which is great for Shimano and Unior cassette and bottom bracket tools (while the Park Tool stuff needs a 1/2″ to 3/8″ adapter).

- It measures torque in both directions, which is often needed for bicycle mechanics in the 30+ Nm range.

Advantages

- Solid quality.

- Optimal handle length and head size (for the torques it is designed for).

- Torque range is great for bike mechanics (it covers all but the lowest torques for which small wrenches are better suited).

Downsides

- A, relatively speaking, downside:

Torque adjustment auto-locks, but you need to hold a spring-loaded ring pulled, while you turn the wrench to adjust it (a video demonstration of this would explain it better than words).

This is faster than some other patents and models I’ve seen, but when you’re turning the wrench to adjust, you see the adjustment once every one turn (360 degrees – unless you “at home with both Nm and foot-pounds, in which case it’s 180 degrees).

I value speed in my workshop, so for me this is more of an advantage, than a downside, but it is fair to note it. - The price is relatively high (I bought it at a discount, and it does get a discount price every now and then).

I use this wrench for everything over 13 Nm, though I love that the above-noted small wrench goes all the way to 16 Nm, because sometimes it’s more practical to work with the wrench you already have in, or at thand.

5.3. Cheap, but good torque wrench

Doesn’t exist.

- Cheap

- Durable

- Accurate

Pick two of the above-listed options – models that promise all three are usually a scam.

5.4. Solid torque wrenches that aren’t too expensive

Beam type torque wrenches have their downsides (slower to work with), but they can be a good choice for those on a budget (or for home mechanics, as the speed is not crucial for that use). A great example is Park Tool TW-1.2 (Amazon affiliate link).

Characteristics

- Torque range of 0 Nm to 14 Nm (accurate in the range of 3 to 12 Nm).

- 3/8″ square socket drive (so you’ll need an adapter for any hex bits or Shimano and Unior tools).

Advantages and downsides

It has all the beam type torque wrench pros and cons (see the section 3.1 of that linked article for details).

Its “older brother,” model TW-2.2 (Amazon affiliate link), covers the range of 0 Nm to 60 Nm (accurate in the 12 to 54 Nm range).

Click type torqe wrenches in the under $50 (perhaps even under $100) price range are often not very good.

A torque wrench I often use is the Park Tool ATD-1.2 (Amazon affiliate link).

Characteristics

- A cam-over (“slipper”) torque wrench (once you reach the set torque it starts slipping, not letting you overdo it) with a range of 4 to 6 Nm.

- It takes 1/4″ hex/bits.

Advantages

- Very accurate, compact, with a torque range ideal for most stems, seatposts etc. (adjustable in 0.5 Nm increments).

- Pretty robust.

Downsides

- Its shape is a bit awkward (even though it isn’t big), so you can’t always easily reach bolts with this tool (I sometimes improvise with longer bits).

- The price is pretty steep for a tool with such a low torque range.

- Bit holder in the (hollow) handle sucks – I took out all the bits and glued the holder’s lid in place so it doesn’t keep unscrewing. Poor design.

- If your hands are even a bit greasy, it is difficult to adjust the torque by hand (the adjustment “barrel” could use a bit larger serrations – I’m considering to use a dremel on it 🙂 ).

6. Conclusion

For the end, I’d like to make an important reminder: if you don’t already know, read the tutorial about how to use a torque wrench properly. The best wrench in the world is not good if you use it wrongly.

Likewise, don’t forget to take care and calibrate your torque wrenches.

With carbon frames and parts becoming more popular, I get this question more and more often, and in this article I tried to answer it as best as I can. I hope this article helps at least one person.

Last updated:

Originally published:

Thank you for a detailed and useful article

Hi Brian,

You are welcome. Glad you like it. 🙂

Relja