This post explains what rolling resistance is, what affects it and how it can be minimised.

1. What is rolling resistance?

Rolling resistance, often referred to as “tyre rolling speed” is the amount of mechanical drag that tyre produces while rolling (with the weight of the rider and the bicycle). Every tyre creates some drag, it is just a matter of how much.

2. What affects the rolling resistance?

Rolling resistance is affected by the following factors:

2.1. Tyre’s mass (“weight”)

Has effect when accelerating, or climbing: the heavier a tyre, the more drag it will produce. This is not a critical factor in practise, for two reasons. First, rider’s weight is a lot greater than the weight difference between a lightest and a heaviest tyre, so tyre’s “weight penalty” is often negligible. Second, apart from starting from stationary, accelerations achieved on a bicycle are relatively small. “Cycling Internet” is full of texts glorifying the famous “rotating mass” (of the wheels), but it can be calculated how little effect extra 100-200 grams of tyre weight have on acceleration of even a light rider (as nicely calculated in this article: Wheel performance – rotating mass and aerodynamic drag).

Of course, the wider a tyre (tread pattern and material being the same), the more mass it has.

2.2. Tread pattern

Knobby tyres will produce more drag than slick tyres. The greater grooves (or knobs) a tyre has, the more rolling resistance it produces (all else being equal). The difference is easily felt and measured. Slick tyre grip on (wet) pavement is explained in the post about Slick tyres. Of course, when riding in mud, sand, or snow, knobs and deep tread pattern will provide better traction and they are beneficial in such conditions.

2.3. Sidewall and rubber compound quality

Tyres with easily flexible sidewalls produce less rolling resistance. Greater percentage of energy used to bend the tyre at the contact patch with the ground is returned once that part of the tyre is rolled off the ground. Tyres with fine sidewalls are usually more sensitive to sidewall damage (sharp rocks etc.), but for riding on paved roads this is usually not a problem.

Sidewall quality can often be deduced from the number of (casing) threads per inch (“TPI”) that manufacturers usually note. More layers of thinner casing threads usually results in lower rolling resistance. This is where bicycle tyre manufacturers often resort to “cheating” – making a tyre out of two, or three layers of thicker threads, and noting an aggregate of both (or all three) layers’ threads as “TPI”. Good quality tyres often have three or more layer casing, with over 100 threads per inch for each layer (so “over 300 TPI”). This effect makes a relatively large and measurable difference.

Another advantage of tyres with good quality sidewalls (a lot of TPI) is they are more comfortable at the same pressure, compared to tyres with “rougher” sidewalls.

Tyre compound is mostly a manufacturers marketing departments’ playground. Every now and then a “new, revolutionary compound” is made – with “better grip, lower rolling resistance and longer wear”. Call me a retro-grouch. 🙂 Based on TPI and tyre’s intended use (racing, winter, touring etc.), compound is usually well matched and there aren’t vast differences.

2.4. Aerodynamic drag

The simple part: the wider a tyre and the more pronounced tread pattern (or knobs), the more air drag it creates. However, since rider attributes to about 90% of the bike’s total air drag, tyres’ effect is not that significant. Yes, aero drag increases exponentially with speed increase, but the rider still remains the most significant factor.

2.5. Air pressure in the tyre

The further a tyre’s pressure is from optimal (whether too high, or too low), the more rolling resistance a tyre will produce. Pressure being too low slows down more, while pressure being too high decreases comfort and grip more than the rolling speed. For explanation of optimal pressure, read: To what pressure should I inflate my bicycle tyres?

2.6. Tyre (wheel) diameter

The greater a wheel’s diameter, the faster it will roll over bumps, potholes and road irregularities. A wider tyre will also be “taller”, increasing a wheels (outer) diameter. Detailed explanation of dimensions: Bicycle tyre sizing and dimension standards.

2.7. Tyre width

If pressure, tyre compound, sidewall quality and tread pattern are the same, a wider tyre will produce less rolling resistance. This will be explained using picture 1.

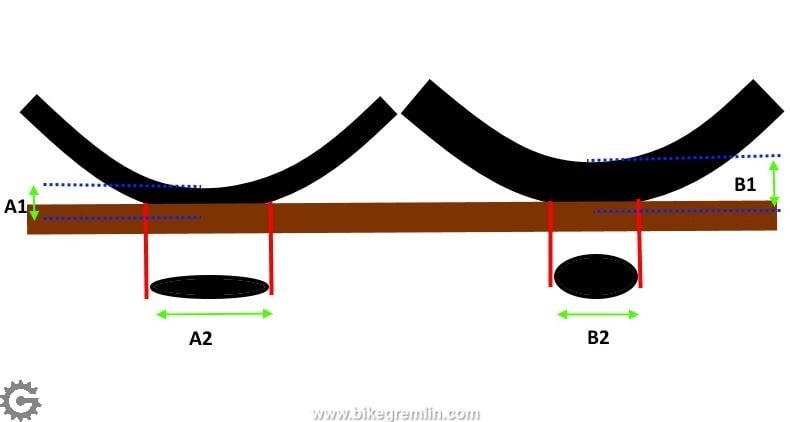

Picture 1

As it is shown in picture 1, total height of the narrower tyre (A1) is compressed by about 1/3 at the point where the tyre contacts the ground, while the height of the wider tyre (B1) is compressed by a fraction of its total. A wider tyre, at the same pressure, can bear more weight than a narrower one.

The other important factor is the length of the contact patch (A2 and B2). A wider tyre deflects by a smaller margin of its longitudinal cross section, so a smaller section of sidewalls is deformed, which results in less resistance. Contact area is the same size, but a narrower tyre gets deformed more, becoming less round, which increases rolling resistance.

In practise, narrower tyres are usually inflated to a higher pressure than wider ones (for the same rider and bicycle weight), so they are not slower in real life, but a common misconception is that (good quality) wider tyres are (significantly) slower.

2.8 Road conditions

The rougher a road, the slower a narrow tyre is (in addition to being less comfortable). Due to higher pressure necessary to prevent pinch flats, narrow tyres tend to bounce more.

Same goes for off road riding – here, tyre width is important, as well as having knobs if the surface is soft (sand, snow, mud).

3. Conclusion?

When choosing a bicycle tyre width, the main criteria should be bicycles intended use. Rolling resistance is mostly affected by tyre’s type and quality. After all the important factors have been explained, a simple(r) rule of thumb list will be given:

- More comfort is desired – wider tyres (with good quality sidewalls). There is a point of diminishing returns here – after which adding more width gives very little gain in comfort, and mostly adds weight. For good quality pavement 28 mm tyres are all one needs. Poor pavement: 37 is the point after which there’s very little gain in comfort. For off road 40, or even 50+ mm makes sense. Small 26″ wheels benefit from tyres of 40+ mm width, even on pavement, since a narrow tyre makes the wheel’s effective diameter smaller, and since 26″ wheels are rather small to begin with, they roll better with tyres on the wide side (slick profile for pavement, of course).

- Off road riding (mud, snow, or sand) – wider tyres with a knobby tread pattern.

- Riding on poor quality paved roads – wider tyres with a slick profile are often both more comfortable and faster.

- Paved road riding – tyres with a slick profile, good quality sidewalls and of width to match the desired level of comfort. Anything narrower than 25 mm brings significantly less comfort, with hardly noticeable (and hardly measurable) speed benefits.

From author’s opinion and experience, tyre’s quality and tread patter have a lot more effect on the “rolling speed” than tyre width. Depending on riding conditions, one can choose an optimal width, thread pattern and tyre quality.

Related post – Slick bicycle tyres:

Last updated:

Originally published:

> a wider tyre (within some width limits) will make a more aerodynamic shape than a narrower one, hence reducing the air drag.

What? The tyre shape itself roughly similar for each size, but the wider the tyre, the its larger cross-section is -> more air drag it creates. Also, the object with rotation axis perpendicular to air stream, such as tire and wheel, creates MUCH more drag than static one due to much higher linear speed at extreme points.

Otherwise, thanks for the article. Good job.

Hi Igor,

The tyre forms a shape combined with the rim. Having a tyre too wide, or too narrow can increase the air drag, compared to an optimal aerodynamic shape (teardrop profile).

Hi Relja,

Well, that’s a nice point, but as an aircraft engineer I’m pretty sure the shape itself only makes any difference if you measure air drag of the same tire on different rim widths.

Drag force is linearly dependent on cross-section and body drag coefficient and there’s no way how tire shape may shift drag coefficient hardly enough to compensate for increased cross-section area.

Cheers,

Igor

Hi Igor,

We have a rim of a given shape and width.

When choosing a tyre to fit onto it, if aero drag is a concern, different tyre widths will sit differently, creating a different shape combined with the rim. Here’s an example of several various different tyre models on differently wide rims:

Are you sure that a wider tyre is necessarily always less aero compared to a narrower tyre, on a given rim width (comparing the same tyre tread profile, i.e. slick tyres)?

EDIT / P.S.

I’d be happy to edit the article, as soon as we confirm the facts.

Another problem I see is that aero tunnel testing is not always relevant for cycling in cross winds, and other factors involved on the road, so I’m sceptical of how conclusive even that could be. On the other hand, I’m not sure how to conduct “real life testing” to be repeatable and comparable.

Relja,

Let me give an example.

As I said previously, total drag is directly dependent on object cross-sectional area and dimensoinless drag coefficient determined by object shape.

If we compare 23 mm and 25 mm tires, the their frontal cross-section areas would differ by 8-9% if tire profile is considered absolutely round.

Unfortunately there is no way to empirically assess or effectively calculate difference in drag coefficient between two bodies of only marginally different shape. However, let me assure you that it is highly unlikely that this defference in cases shown on your illustration will exceed even one percent (if rims, tire sizes and tread patterns are the same, of course).

Note that these are ultimately simplified estimations based on basic aerodynamic ideas; rotating bodies aerodynamics is much more complicated (and I’m pretty happy I’m not a helicopter designer). Overall dependencies are still applicable though.

Speaking about crosswinds testing, I would say that above noted dependencies are generally fair to some point even when the airflow vector becomes different from head-on. By the way, “teardrop”- and egg-shaped tires will become rather “flat”- or “plate”-shaped (and also have slightly larger cross-section) if you look at them from the side. I don’t think there is a difference worth considering though.

P.S. Sorry for not replying directly to your posts, no idea how to do it properly.