This article will help you know what’s what when it comes to bicycle forks and headset bearings. It should help you when servicing or buying forks or new steerer (headset) bearings – because for both “Googling” and talking to bike shop people, it helps when you use the proper terms (to avoid misunderstanding).

TL/DR

After you’ve read this, you’ll know the difference between threaded and threadless forks, and understand the “EC,” “IS,” and “ZS” headset bearing acronyms like a pro! 🙂

Did I mention “tapered forks?” Yup – you’ll understand those too. 🙂

The full fork & headset article series:

- Bicycle fork models and brake mounts

- Headsets [01] Names of fork and headset parts

- Headsets [02] Important fork, head tube and headset dimensions

- Headsets [03] Headset bearings standards – SHIS

1. Fork

Bicycle fork is used to connect the front wheel to the bars and to enable steering by rotating the bars (and the front wheel). Picture 1 speaks for itself. Important fork parts and dimensions are marked.

1. Steering column

2. Fork crown

3. Steering column length

4. Steering column diameter

5. Fork crown diameter

Picture 1

Steering column and fork crown diameters are measured on the outside (outer diameter), best done using Vernier calipers. Fork crown sometimes comes with an integrated race for headset bearings, while more often the race is bought with a headset and pressed onto the fork crown when mounting the headset and the fork.

1.1. Fork types (in terms of headset and attachment type)

Basic division is threaded forks and threadless (also known as “ahead”) forks.

Threadless forks come in two versions: with steering column of a uniform diameter along the length – and with a steering column that has a wider diameter at the crown than at the rest of the column length. Forks with a wider steering column diameter near the crown are called “tapered” forks.

1.1.1. Threaded forks

Easily recognized by the threads on the top part of the steering column. Threadless forks with a steel steering column of an appropriate diameter can be converted to threaded by cutting threads on the steering column.

Picture 2

Threaded forks are attached to the head tube (and the bearings are preloaded) using two (lock) nuts – one with a cone to press against the bearings and another to lock the first one in place.

Source: bicycletutor.com

Picture 3

1.1.2. Threadless forks with a steering column of a uniform width – “ahead” type

Easily recognized – no threads and uniform (not changing) width steering column.

Picture 4

1.1.3. Threadless forks with a steering column wider near the crown (tapered)

These forks are called “tapered”. They are similar to ahead forks, except that steering column is visibly wider at the bottom (near the crown). Tapered fork design is commonly used on modern frames.

Picture 5

1.1.4. Mounting threadless forks (both ahead and tapered)

Threadless forks (both ahead and tapered) are held in place with a stem (that holds the bars as well on the other end). A special “star” is inserted into the steering column. The star has threads for a bolt in the middle. A cap is then screwed on top, to moderate the bearing preload – pushing the stem and spacers (optional, but common) below – which then preload the bearings. Once a desired preload is achieved, the stem is tightened against the steering column to hold it all in place.

Source: www.livestrong.com

2. Head tube

Head tube is a part of a bicycle frame (a tube) where the steering column (fork tube) goes through. Headset (steering bearings) is placed on top and the bottom part of the head tube. Important dimensions are marked in picture 7.

1. Head tube length

2. Top head tube bore diameter

3. Bottom head tube bore diameter

Picture 7

2.1. Head tube bores

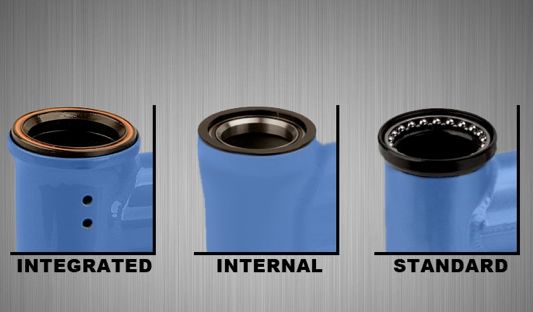

Depending on what kind of bearing (cups) the head tube was designed for, there are three types of bores: for external (or “standard”), integrated and internal bearings.

2.1.1. Head tube for external (also called “standard”) headset bearings

Easily recognizable by having the same (inner) diameter along the whole length. Cups are pressed into the tube, as will be explained in chapter 3. that deals with headset cups. Top and bottom bore diameters are always the same.

Picture 8

2.1.2. Head tube for integrated headset bearings

These tubes have specially shaped top and bottom bores to support headset bearings. Bearings are usually inserted (without the need for pressing) directly into the head tube, less common is a design with cups that support the bearings. Deeper part of the bearing support is cut at an angle of 45 degrees (older 36 degree standard now considered obsolete and frames are no longer manufactured with that standard).

Lower part of the seat is cut at an angle.

Source: www.parktool.com

Picture 9

This system, without the need for pressing in headset bearing cups cuts bicycle manufacturers’ production costs (headsets are cheaper and take less time to assemble them on the bike). Since head tube bores are not manufactured to strict enough tolerances, these bearings can sometimes damage the frame, because they don’t sit tightly enough inside the head tube, which also “acts” as a bearing cup.

With this system, bottom headset bore can have a greater diameter than the top one, which requires a tepered fork.

2.1.3. Head tube for internal headset bearings

Besides “internal“, this system is also called “Zero-stack“, “semi-integrated” and “low profile“. Head tube is of relatively large outer diameter (about 50 mm usually), to allow bearings to fully sit inside the head tube. Bearing cups are, like the external ones, pressed into the head tube, but here they go practically all the way in, with just a thin “lip” left wider to prevent them from going all the way in.

Bearing cup sits almost completely inside (flush with the top of) the head tube.

Source: www.parktool.com

Picture 10

With this kind of head tubes, it is common that bottom headset bore has a greater diameter than the top one, i.e. tapered forks are used.

3. Headset bearings

There are three types of headset bearings, matching each of the three head tube types: external, integrated and internal. Each standard’s bearing layout (parts) will be explained in further sub-chapters.

3.1. External headset bearings (External Cup – EC)

External headset bearings come in two types: for threaded fork steering column and for threadless (ahead system, not for tapered). They are referred to as External Cup (EC).

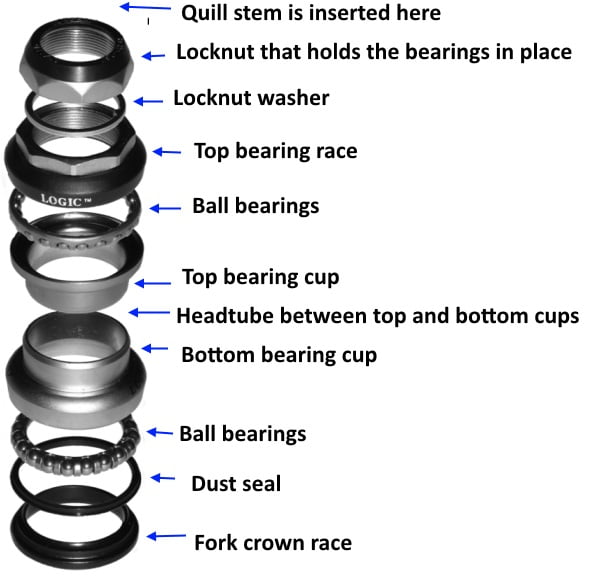

3.1.1. External headset bearings for threaded fork steering columns

Picture 11 shows the parts of a typical bearing of this type:

Picture 11

There are also versions with roller bearings instead of ball bearings, but principle and basic parts are the same.

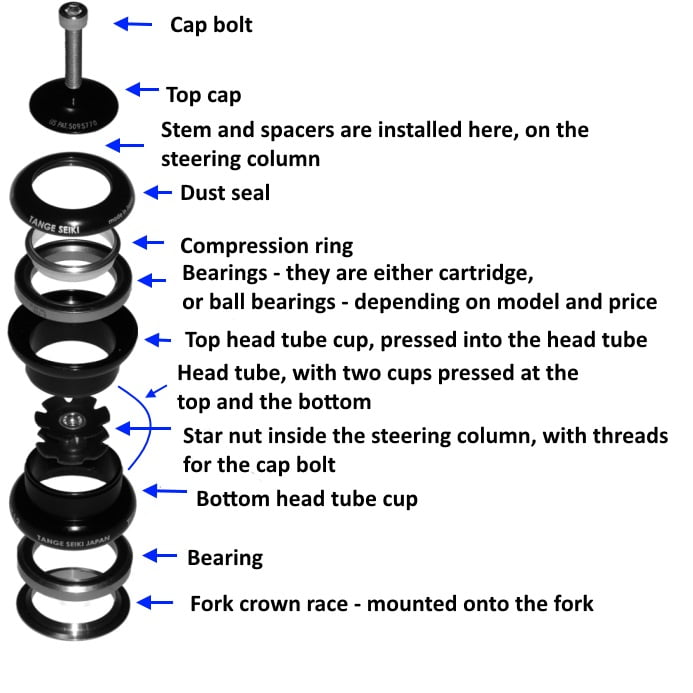

3.1.2. External headset bearings for threadless (“ahead”) forks

Unlike threaded steering column bearings, these bearings use a bolt to adjust the preload – and the stem is then tightened to the steering column to hold the adjusted preload and the whole system in place.

Picture 12

3.2. Integrated headset bearings (IS)

System of adjusting (and maintaining) the preload is the same as for external ahead bearings. All the other parts are also practically the same, except that head tube acts as the (top and bottom) cup. That is the bearings are placed (i.e. “slip-fit”) directly into the head tube, without inserting, or presing any bearing cups in. Bottom bearing can have a bigger diameter than the top one (for tapered forks).

Typical integrated headset (for a tapered fork) is shown in picture 13.

Picture 13

Modern headset bearings come with a 45 degree angle (that is the angle of the taper in the frame that the bearing’s taper should match). The (SHIS) mark for that bearing can be “36-45”. The first number refers to the inner angle, the contact between the bearing’s race and the centering cone on the fork, which is at 36 degrees.

Obsolete standard frames came with a 36 degree angle (and such bearings are marked as “36-36”).

If I’m not mistaken, Campagnolo (and some frame manufacturers) specifies “45-45” degree bearings. So that’s the third “standard” (with a 45 degree angle both on the frame and the centering cones).

It is quite difficult to find matching bearings for this standard. These are proprietary cycling bearings, and most shops don’t have all the needed dimensions and angles noted. However, when you buy a set of headset cups (since the bearings themselves are not easily sourced as they are bike-proprietary dimensions/types), you usually get them with a set of centering cones, so you only need to worry about the outer angle (the one that matches the frame’s headtube angle for installing bearings).

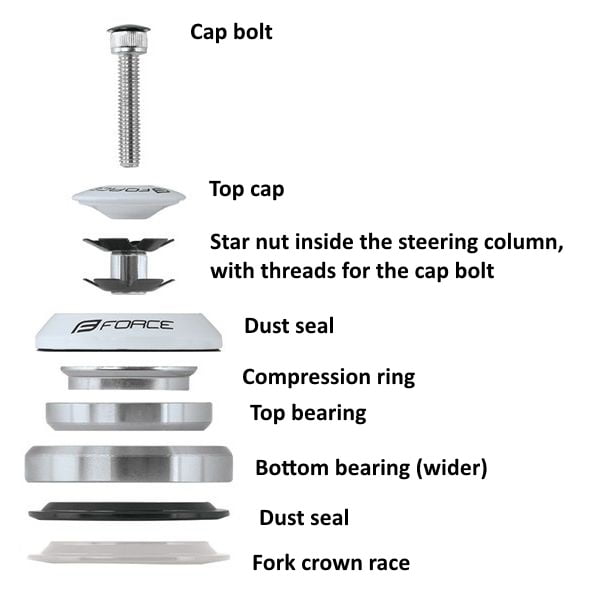

3.3. Internal headset bearings (“Zero Stack” – ZS)

Internal headset bearings use cups that are pressed into the head tube and go almost all the way in – only a thin widened part of the cup stays outside, siting flush with a head tube end. Internal headsets are also called: “Zero-stack“, “semi-integrated” and “low profile“.

They have the same parts (by function and layout – i.e. stacking order) as ahead bearings, just the cups are differently designed to fit almost completely inside the head tube.

Left – internal

Right – external

Picture 14

Overview of the three headset standards for threadless forks – ahead (external), integrated and internal – is shown in picture 15.

Source: www.vitalbmx.com

Picture 15

This sums up the fork and headset parts important for steerer bearings. For the important dimensions and how to measure them read: Important fork, head tube and headset (bearing) dimensions, while dimension standards are explained here: Bicycle headset bearings standards – SHIS.

Last updated:

Originally published:

Related post – Bicycle frame geometry explained:

Just found your site yesterday. Great content! I have an old ’81 Miyata 912. Original headset, or it’s o.e. replacement has become indexed by brinnel. I want to upgrade to this https://www.innicycle.com/

Seems to be an upgrade even with the same technology, and I get to keep the original fork while also modernizing the headset and stem riser. I did briefly read your post on quill stems, and I hadn’t heard of the stem bolt breaking. Now that I’ve read your thoughts, it does concern me.

Still, I’m keen on keeping the frame and fork together unless you have a much better idea. The cost is a bit high, but you’re also getting a semi integrated headset with sealed bearings.

I’m curious to know your thoughts?

Hi Tony,

That INNICYCLE product doesn’t fix the inherent safety concern about threaded stems – i.e. it’s still all held on via one bolt.

What it does is two things:

1) Allow you to use a modern 1 1/8″ threadless stem on a threaded fork (but the part that stem is tightened against is still, again, held on by just one bolt).

2) Make bearing preload adjustment simpler – by letting you use the same method as for ahead (threadless) stems.

That’s why I would rather spend (a lot) less on some decent-quality bearings and call it a day.

Though that does look nice and neat, so if the price is not a problem – I would be tempted. 🙂

For any safety concerns, for the “ordinary” threaded steerers and stems, I suppose one could improvise and machine some clamps, joined by some rods. Having one be very thin and held in place by the headset preload locknut – and the other be tightened around the stem, so there is some connection and control in case the bolt holding the stem in place breaks. Perhaps a good mechanical engineer could design a better patent – this is just the first idea that came to mind.

single bolt using a steel steerer stem should be fine but i have seen alloy steerer stems break,never seen a bolt snap yet,but it would be very possible if it was over tightened,i still use old steel steerer stems with just that single bolt on a 1 inch steerer,go all steel there if your using a 1 inch steerer