Explanation of all the important facts related to bicycle front derailleurs. A separate article explains the front derailleur compatibility.

1. How does the front derailleur work?

Front derailleurs (FD in the remainder of the text) are used on bicycles with external gearing and (usually) multiple sprockets at the rear hub. They work on a simple, brute force principle: moving the chain sideways, until it slips off a sprocket onto the adjacent one.

This derailleur movement is usually operated via shifters (shifter levers), that are located on the bars (or somewhere at hand). Shifter cable is attached to shifters at one and and at the derailleur at the other end.

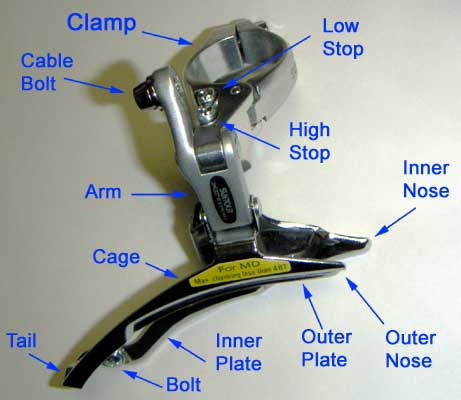

It consists of a metal cage and a spring. The spring moves derailleur to one side when the shifter cable is released, while the shifter cable, when pulled, moves it to the opposite side. If there is no rear derailleur installed (only one sprocket at the back), a chain tensioner will be necessary to gather chain slack when shifting from bigger to smaller chainrings up front.

2. FD mounting to the bicycle frame

Front derailleurs are mounted to the frame via a built in clamp, or on a braze on frame holder. Derailleurs designed for braze on holder can be put on frames without braze ons, using a clamp with braze on.

Which one of these derailleur mount types is used, depends on the frame and derailleur type that is available. Frame with braze ons will have problems accepting clamp type FD-s, because braze on holder will get in the way (did someone just say “angle grinder”? 🙂 ). For mountain bikes, a few new direct mount systems have been introduced, that differ from the classic “direct” (braze on) systems (still used on road bikes). Following (sub) chapters will explain those standards.

Common clamp mount diameter standards are 28.6 mm (common on old, steel frames), 31.8 mm and 34.9 mm (common on modern aluminium or carbon fibre frames).

The number of teeth on the largest chainring, and the chainstay & seatstay angles are also important specifications. For more details, see the 3rd Chapter in the article about front derailleur compatibility.

2.1. Direct mount system known as H0, or DM

FD is attached directly to the frame with one bolt, and has a groove on the back side to help hold it in place. The frame must be made with an appropriate mount (with a matching groove) for this kind of FD to fit.

2.2. E-type (also known as low direct mount, E2-type, S3, Spec 3)

First versions pre-date the DM system and these FDs came with a back plate mount that was fixed by threading in the (threaded) bottom bracket.

This is what the mounted E-type FDs look like:

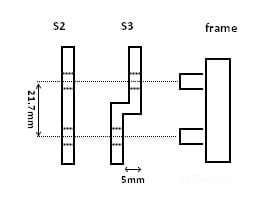

Openings (cutouts) for mounting (screwin in) are cut at a 22.1 mm horizontal distance on the FD, while the front opening is 5 mm towards the outside (away from the frame) than the rear one.

SRAM marks their E-type FDs as S3 (Spec 3), while Shimano’s mark is E-2.

Shimano’s E-2 FDs allow for height and angle adjustment (mounting holes on the FD are cut with a longer vertical opening and are a bit wider than the mounting bolts), while with SRAM’s S3, one needs to pay more attention to the size of the front chainrings that the FD is made for, since they don’t allow any wiggle.

Apart from this E-type, SRAM offers two more (very similar) mount standards: S2 and S1.

2.3. SRAM S2 (Spec 2)

Easily confused with SRAM S3 (and Shimano E-2), since the mounting holes are made at the same distance (22.1 mm), but the front and the rear one are at the same height. The FD itself when mounted sits a lot furhter outward (towards the chainrings, away from the frame) than the S3 (E2) type.

S2 (left) and S3 (middle)

2.4. SRAM S1 (Spec 1)

S2 FDs have mounting holes at a 42.7 mm distance.

3. Double vs triple

With FD-s, number of sprockets at the back they are made for is more or less a marketing trick. E.g. an 8, or a 10 speed FD will function more or less the same. Cage width will differ, but if one “size” is missed (9 speed with an 8 speed chain), it will not cause any problems.

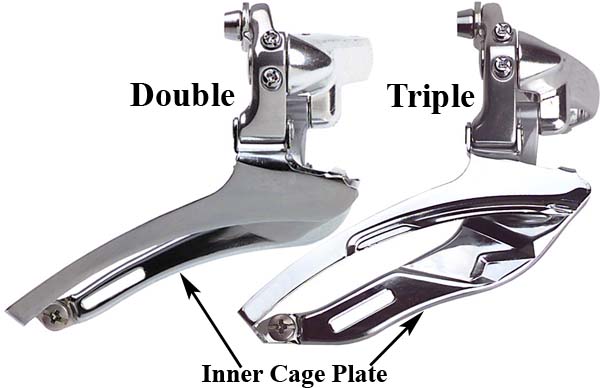

Important thing, though, is the number of front chainrings. There are FD-s for two (double) and those for three (triple) chainrings. Mixing is not advised.

Lower inner cage plate of triple FD comes closer to the chain when it is on the smallest chainring, helping with shifting. Double FD will shift poorly with a triple chainring setup. Triple FD will work decently on a double chainring setup though, as long as the difference between the big and the small ring isn’t greater than 14 teeth.

Double FDs can easily handle up to 16 teeth differences in chainring size.

4. Cable pull: bottom vs top pull

First FD-s were made so that cable is routed under the BB then up to the FD. So FD was pulled from the bottom. With popularization of MTB-s and off road cycling, this design caused some problems. Cables were easily covered in mud and even damaged on rocks. Cable routing was then transfered to the top part of the bicycle (along the top tube). That is when the first top pull FD-s emerged.

Nowadays, MTB derailleurs are often double pull – designed so they can work with both bottom and top pull cable routing. Road FD-s are usually designed with bottom pull, the traditional way.

Enables routing from either side. Here, two cables are routed, from the top and from the bottom. Of course, only one cable is mounted in real life – either from the top, or from the bottom. Never two! 🙂

Shimano Side-Swing FD-s are explained below (chapter 5.), but here it suffices to say that they use a different cable routing (cable comes from the front) and the frame needs to be built to accommodate such cable routing.

5. Swing (pivot) position and direction

FD cage rotation and position of mounting clamp relative to the cage are closely related, so this chapter could be placed under the chapter 2 (“FD mounting to the bicycle frame“).

5.1. Bottom swing (High clamp)

Older FD swing standard (still used on road bikes) is the high clamp: the cage swings at the bottom of the parallelogram, fixed to the body of the derailleur. This system is called both “bottom swing” and “high clamp” – but note that the new(er) side-swing FDs also come with both high, and low clamps.

5.2. Top swing (Low clamp)

Newer standard, introduced for mountain bikes is the low clamp. The cage swings above the FD body. That way the body is closer to the BB and leaves more clearance for rear suspension linkage on the seat tube – for example.

5.3. Side-Swing

Newest (Shimano’s) system where the FD moves sideways. It is made to provide more clearance for ever wider tyres and shorter chainstays, so that a proper chainline can more easily be maintained. Side-swing FDs can be attached to the frame via low, high clamp, or direct mount. Before the introduction of this system, the clamp position was enough to determine the FD cage rotation (top, or bottom swing), but side-swing has “messed that up” a bit. For example, a high clamp FD used to always be bottom swing, but now it can also be a side-swing one.

6. Number of speeds, compatibility

Detailed explanation of which FD-s can be combine with which shifters, chains etc, can be found in this series of articles: Compatibility.

Like it was mentioned before, speeds of FD-s are a marketing trick. Even FD-s and FD levers of various makers can be mixed (e.g. Shimano and SRAM). Still, attention should be paid to the following two factors:

- MTB and road FD-s, and shifters (as well as the cranksets) have different cable pull ratios (and chainring spacing) so they are not compatible and shouldn’t be mixed.

- Double and triple shouldn’t be mixed.

Last updated:

Originally published:

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/front-derailleurs-explained-article-comments.140/

Good Stuff for a newb like me attempting to work a sram xx grip shifter (2×10) with a deore FD. There appears to be a lot of fuzz around this topic. Appreciate the straight line intel, the mud is clearing.

will shimano cx70 front derailer work on triple, running 44/34/24 front and12/34 rear

It is designed for 2 chainrings, not a triple. Also, for larger chainrings (46 to 52 teeth on the largest one).

So I would not expect it to work very well. In fact, I’d be (pleasantly) surprised if it did.

If we are talking about this model:

https://bike.shimano.com/en-EU/product/component/cyclocross-and-onroad-hydraulic-diskbrake/FD-CX70-F-D.html

thanks for explaining top and bottom pull … I’m working on setting up a derailleur now that can be configured as both … and it was mystery as to why there were cable grooves on the damn thing that were not being used …

Hi Relja,

I want to change my 36/22 crankset (i don´t like the big 14t jump) to a 36/24 or even 36/26, my derrailleur has 14t capacity (Shimano FD-M4020).

Do you think the new setup could work well? Or probably i should couple a 36/26 Fc-M4100 with a FD-M4100-M derailleur (10t capacity)

Hi Leandro,

I don’t think that the FD would mind if the tooth difference is reduced.

Problems could occur if you did the vice-versa thing: using a 10T capacity FD for a 14T chainring size difference.

But using a 14T capacity FD with a 10T chainring size difference should be fine.

I’m doing almost the exact thing on my road bike (using 53-42 cranks, with a FD designed to work with 53-39 cranks).

Relja

Hi Relja,

I have come across your page while looking for info to rebuild the drivetrain of my bike. It is impresive the amount of material you have uploaded. It will take some weeks to review all the contents. Thanks a lot!

My issue now 🙂

Due to my mtb frame characteristics I have been looking for a FD with top pull and low clamp. The dual pull options I have tried were high clamp (Shimano SLX FD-M7025-11 2-/11-speed) and the guiding towards the FD was akward and mechanically poor due to the cable stop orientation. No trace of top pull, low clamp available out there. Result: I gave up the 2×11 idea

Next target is 2×10 so I have scanned the whole Internet looking for a low clamp, top pull FD. I managed to find a model that it is still in stock (Shimano SLX FD-M675). “Problem”: Vendor information states that the FD largest chainring is 40/38 teeth, while I was planning a 36/26. I contacted Shimano but they stick to the official speech, of course! 😀

What’s your opinion on using this FD Shimano SLX FD-M675 with a largest chainring of 36 teeth? Will shifting be compromised?

I have read the info in your site regarding FD and I am aware that the FD-M675 will have a larger curvature than the 36T chainring which could cause some chain rubbing. What are the chances this will occur taking into account the teeth discrepancy is only 2 teeth (38 vs 36).

Thanks a lot for your help,

Joaquín

Hi Joaquín,

You are welcome. 🙂 Yes, I’ve practically written several books online on my websites over the years. Primarily for my own reminder and reference, but it’s great to see they are also helping the others. 🙂

FD chainring sizes basically affect the curve of the cage. There are two possible mismatches here:

1. FD is designed for fewer teeth than the chainrings actually have (not the case in your situation)

In order for the rear part of the FD cage to not hit the largest chainring, FD cage needs to be placed too high, sometimes almost 1 cm above the largest chainring.

This results in slow and poor shifting.

2. FD is designed for more teeth than the chainrings have (the case in your situation)

Depending on the frame’s design, the rear side of the cage could be hitting the chainstays, hence, again, forcing the mounting point to be pushed higher, resulting in poor shifting.

If that’s not the case, the problem is less severe. You might experience some more chain rub even when not severely cross-chaining. And shifting will still not be perfect, but if the cage can be set to the optimal height (i.e. the bike frame not getting in the way), shifting can be acceptably good.

Hope this helps.

Relja

Thanks for your reply Relja!

Well, I am coming from a 3x setup with a big 44teeth chainring so I don’t expect the FD hitting the chainring. I am more concerned about rubbing issue and shifting.

Obviously is try and error but with a cost. The last option would be moving to a 1x setup…. Not my cup of tea but at least I will get rid of the FD burden. Other issues will pop in with 1x (Chainline mainly) but for that I will ask you in the correct thread 😉

Thanks a lot and congrats for your site!

Joaquín from Belgium

Hi Relja,

I am trying to work out the difference between the following Shimano front derailleur part numbers. The code extension is either a “3” or a “6”. For example the following codes are from the current Shimano product range but three us no explanation as to the meaning of the extension number. The 3 and 6 extension numbers appear throughout their interchangeability tables.

FD-TY500-TS6

FD-TY500-TS3

Can you help?

Kind regards

Allan

Hi Allan,

It’s the chainstay angle.

FD-TY500-TS3 is for 63 to 66 degrees.

FD-TY500-TS6 is for 66 to 69 degrees. 🙂

For more details and a more thorough explanation, see the article FD compatibility – chapter 3b.

Relja

I have a ICE recumbent trike, on which I’ve mounted a mid-drive motor. It has a double chainring that extends outward from the frame more than the prior crankset. The old 3×9 down pull FD is unable to extend out enough to reach the large chainring.

The normal solution is using a direct mount adapter that extends out the derailleur beyond a standard clamp mount, as typically used used on MTB with fat tires. My problem is finding a compatible front derailleur. I’ve searched the web for hours and can’t seem to find the right one. My lack of knowledge doesn’t help.

It needs to be down pull. I believe either a double or triple will work with my friction Microshift bar end shifter. My largest chainring is 42, smallest 34.

Further problem – the 42 doesn’t give me a very high top speed. I’d like to sift to a larger chainring in the 48-52 size if that is possible. I would increase the small chainring accordingly.

Can you suggest a compatible FD for my situation?

Hi Jim,

Several things to consider here for the FD (please correct me if I got something wrong):

1)

It should preferably be mounted without a clamp, so you can mount it on an adapter and make it “sit” far out enough to reach all the chainrings.

Since it will require a custom-made mount, I suppose it doesn’t matter if the FD is a direct mount, or the older standard that is fitted onto a brazed-on clamp equivalent.

I also suppose that swing direction is not important (top swing, bottom swing or side swing should all work).

2)

The cable should be coming from the bottom (bottom pull).

3)

Shape should match a chainring of about 50 teeth.

4)

It should work with double chainring cranks

Considering all that, I’d go with:

Shimano Sora FD-R3000-F (Shimano website link)

That FD is of decent quality yet it doesn’t cost too much. It should easily handle the largest chainring of a size going from 46 to 52 teeth.

It will also work fine with the smaller chainring being up to 16 teeth smaller (like 48-32, 50-34, 52-36 etc.).

Hi Ralja

I am currently running an FD-M618 with a 38/24 and want to run a 40T for a better flat speed. From reading your compatibilty, I cant seem to stop the chain rub in the lower ring on the back of the FD as I need to go high on the frame for it to clear the 40T which lifts the FD to rub on the chain. My question is, what FD should I run to be able to run the 40T and what lower chain ring should i ideally have or will the 24 be okay as its a 16 tooth difference? It also a 2 x 10 speed on a voodoo MTB. Thanks Sean

Hi Sean,

16 T difference generally works fine (allowing you to easily shift from one chainring to the other).

As for the rubbing – with smaller sized chainrings, and relatively short chainstays of modern bikes, it’s more pronounced.

Unfortunately, I don’t know which model would work. It boils down to trial and error. The most likely candidate would be a FD designed for ~40 T largest chainring (most modern double MTB FDs are designed for 36 or similar tooth counts).

Another note: 2 T is not much of a difference for the front chainring (at the rear, 2T makes a lot more difference) in terms of gear ratios. With high-tooth count cassettes available (especially for 9+ speeds), it might make sense to look for 46-30 T cranks (often sold as trekking, or gravel or similar), paired with a matching FD (I saw some Acera class FDs designed for 48 ~ 46 T chainrings).

42 T FDs were readily available for triple cranks, but I don’t think they would play nicely with modern compact cranks.

P.S.

If the chain rub occurs only when severely cross-chained (i.e. using the smallest 3 chainrings of the 10-speed cassette while on the small front chainring), I’d not worry about it, as it isn’t a combination one should generally be riding in.

Relja