What are hookless rims? How do they differ, and what are their pros and cons compared to the “ordinary” clincher rims (the ones with hooks)?

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

Table Of Contents (T.O.C.):

1. What are hookless rims?

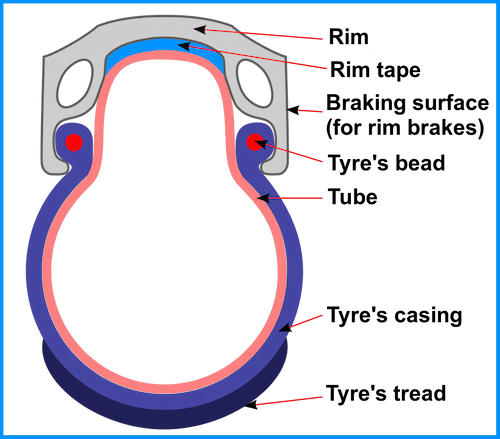

Before answering this question, let us briefly consider the “standard” clincher (or “hooked”) rims. A hook on a rim helps keep the tyre from blowing off when inflated to high pressure, or when it faces sideway forces (like when a wheel starts sliding sideways, and then suddenly regains traction).

Picture 1

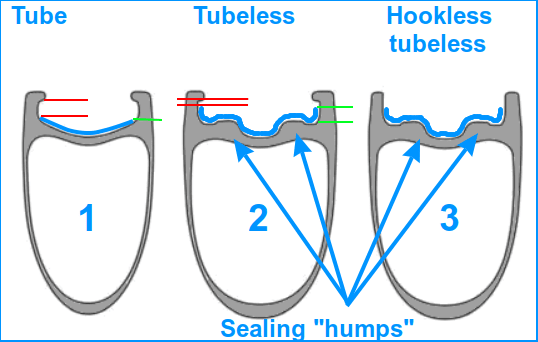

Now, let’s compare clinchers to a hookless rim (the picture is taken from my article about bicycle rim tapes):

Picture 2

Hooks on a rim provide a good anchor for a tyre, thus enabling the use of lighter tyres with more flexible sidewalls. Such tyres would too easily slide off a hookless rim – and thanks to their supple sidewalls they provide a lower rolling resistance. That’s one of the main reasons why people started making rims with hooks some fifty years ago (in the ’70s of the XX century). Pretty quickly, “hooked” (clincher) rims became a standard, replacing practically all the hookless rims.

Today, hookless rims are becoming “fashionable” again. Why? Read on.

2. Hookless rim pros and cons

Hookless rims have the following advantages compared to hooked rims of the same weight and width:

- They’re stronger.

- They let the tyre sit a bit wider on the rim – as there are no hooks pushing the tyre further inwards relative to the rim’s sidewalls. More volume for the same tyre width (and mass) gives a bit softer ride and a bit lower rolling resistance, with a potential for a slight aerodynamic bonus.

- Easier and cheaper to manufacture (especially when it comes to carbon fibre rims).

These advantages are relatively small and hardly measurable. Clincher rims too can be quite light and strong, with a tyre that is seated nicely. The main advantage of hookless rims is for the manufacturers – faster and cheaper production.

Downsides are the same as they used to be fifty years ago: hookless rims require heavier tyres with stiffer sidewalls to prevent them from being blown off the rim at higher pressure or sideway loads. This describes tubeless tyres perfectly: they need beefier and a bit stiffer sidewalls to hold air without a tube, and to prevent them from getting pushed away from the rim and losing pressure upon impacts. Let’s now briefly recapitulate the hookless rim cons:

- Limited tyre choice (boils down to, generally heavier, tubeless tyres).

- Maximum pressure of about 5 bars (70 PSI) – generally.

3. When are hookless rims a good idea?

Briefly: hookless rims make sense for wide tubeless tyres.

Tyres that aren’t tubeless will not work nicely with modern hookless rims!

Before I continue, a brief overview of tubeless tyres:

The main advantage of tubeless bicycle tyres is they can be ridden at very low pressures without getting snakebite flats upon impacts. Low pressure, along with more width, helps on rough or muddy (or snowy) terrain. Also, tubeless tyres can self-seal smaller punctures, thanks to the sealant liquid that is poured inside of them. Their main disadvantage is they are a hassle to mount (because of their stronger and stiffer sidewalls) and regularly change the sealant fluid.

For more details, see the article: Tubeless bicycle tyres – pros and cons explained.

Narrow road bike tubeless tyres require higher pressure, so they don’t use the biggest pro: the low-pressure “operation” (also, self-sealing works worse at higher pressures), while not avoiding any of the tubeless tyre cons.

To be more specific, I’ll quote my reply to Ryan:

For the purposes of this article, for average rider+bike+luggage weights, I would say that narrow tyres are below 37 mm (or below 1.5 inches). Though, on a light road bike, ridden on paved roads, one could consider a 32 mm tyre to be a low-pressure, wide tyre.

It boils down to what the optimal pressure for the riding conditions and the whole system weight is (optimal tyre pressure article).

If your optimal tyre pressure is over 4 bars, I would avoid hookless rims (or tubeless tyres for that matter).

Do you now understand why I think hookless rims are a bad idea for road bikes – or any other bikes without wide tubeless tyres?

What about the wide (MTB) tyres? If you think tubeless tyres are a good idea (considering their pros and cons), it makes sense to pair them with hookless rims.

Let me wrap this up with a quote:

It is somewhat funny that a feature that when introduced was thought of as being such a big improvement (hook beaded rims, allowing far higher tire pressures) is now considered no longer needed because we have basically gone back to tire widths and pressures that were the norm 60+ years ago on performance bikes. This industry is truly cyclic and suffering from short term memory

From what I have read and been told one of the major motivators for hookless rims is because the molding of the hooked edge with a layered material construction (carbon tow/cloth in plies), the compression needed for the strength and the shape/dimensional control required makes for a very complex mold with what is called “negative draft” (the overhang of the hook edge WRT the rim’s inner side wall). Eliminating that hook edge opens up the rim interior and reduces the mold’s cost and complexity by a lot. Now it only leaves convincing the public that tires that are less securely held on the rims (or so hard to mount or remove that on the road repairs are vastly harder to do) is a good thing. Entering from the left is the marketing department…

Andy – from BikeForums

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

After I bottomed front and rear simultaneously in a big hole on the road and pinch flatted both of my brand new tubeless tires beyond possibility to repair, I kind of disagree with your statement (and if many others) that tubeless tires can’t get pinch flat.

Hi David,

That’s an interesting point, worth discussing. Here’s my take on it:

If you hit a tyre hard enough against a sharp enough surface (pothole, sharp kerb or similar), you will cut it. However, the force (and surface “sharpness”) needed to cut a tubeless tyre is several times (at least) greater than what’s needed to make a tube pinch-flat. Let me further explain the difference:

– Tube pinch flats can happen even on a flat surface and are the result of the tyre bottoming out against the rim and pinching the tube stuck between the two. It’s a mechanism similar to tearing the tube during tyre installation (if it gets stuck between the tyre and the rim’s edge).

– Tubeless tyre cuts, on the other hand, are the result of the tyre being literally cut, not of the rim just pinching it. I.e. that’s extremely unlikely to happen on a flat surface, even if the wheel with a very low-pressure tyre hits the (flat) ground hard (landing after a jump for example). For a cut, you need to bottom the tyre out between the rim and something relatively sharp – like a sharp kerb, or a sharp-edged pothole.

In other words, it’s the difference between tearing the relatively thin and soft tube, and cutting the relatively hard tyre. Magnitudes of difference in terms of force, and it could be argued that the puncture mechanisms may look similar, but are in fact different (tear vs cut).

Relja

Good write up, one question is how WIDE is a wide tire size now? How does this play into gravel cycling and their tire widths?

(2.0-2.8”plus) MTB should be hookless and tubeless

What about gravel tire sizes? 38mm – 50mm tires

Agree road should be hooked

Hi Ryan,

That’s a reasonable question – I probably should have been more specific in the article.

For the purposes of this article, for average rider+bike+luggage weights, I would say that narrow tyres are below 37 mm (or below 1.5 inches).

Though, on a light road bike, ridden on paved roads, one could consider a 32 mm tyre to be a low-pressure, wide tyre.

It boils down to what the optimal pressure for the riding conditions and the whole system weight is (optimal tyre pressure article).

If that’s over 4 bars, I would avoid hookless rims (or tubeless tyres for that matter).

Relja

People called me Sasquatch for some odd reason and I have more than 300 pounds of weight plus bicycle.

One day decided to build a new wheel with my first hookless rim that had a terrible blowout mounting a tire on the rim a new was mounted and pressurised accordingly to rim brand and I had another blowout cycling in a strait line.

From this disaster I made a new set of wheels with hookless rims using bigger tires and limiting pressure down to 37 PSI from 40 PSI but another blowout happened at speed with the front tire.

My super weight does not allow me to go lower than 33 PSI the rear starts to wobble a lot.

Now I am going back to rims with hooks.