This post will explain the basic principles of mechanical brakes functioning, i.e. brakes that use cables. Hydraulic brakes will be explained in a separate article. Though I have made a video explaining hydraulic brake working principle. Different post explains brake (and shifter) cable and housing standards.

1. Introduction – mechanical advantage

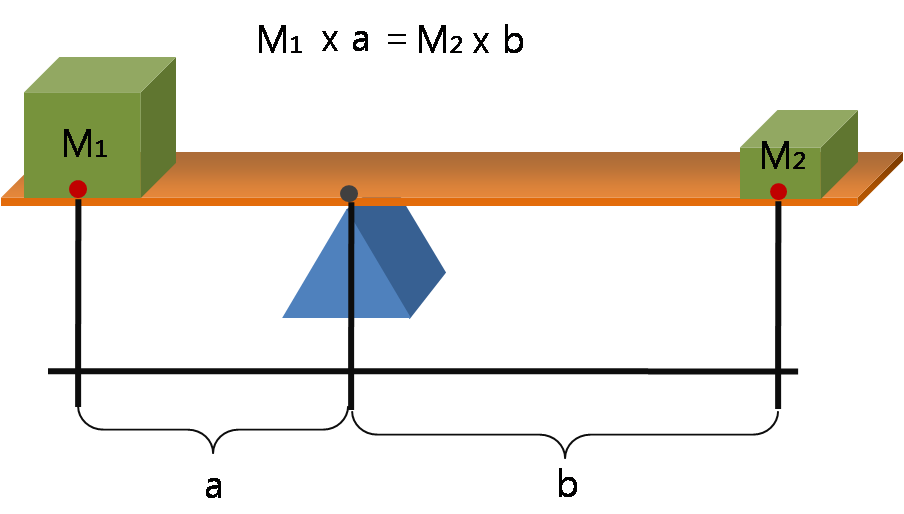

Mechanical brakes work on a simple lever principle.

The longer the leverage, the less mass is needed to move a greater mass. Also, for moving a great mass over the same distance, the longer the lever, the more distance needs to be covered by the mass used for moving the larger mass.

Ratio between levers is called mechanical advantage. So if lever b is twice longer than lever a (in the picture above), 1 kg of mass M2 will be enough to lift 2 kg of mass M1. However, in order to lift mass M1 for 10 cm, mass M2 will need to cover a larger distance.

2. Mechanical advantage for mechanical brakes and the amount of lever cable pull

Lever principle is used for mechanical brakes. Brake lever can travel about 20 degrees until it reaches the bars. That is the maximal travel. Brake pads are placed about 1 to 2 mm from the wheel rim, or disc rotor.

The less cable is pulled by the brake lever during it’s complete 20 degree travel, the higher mechanical advantage. The less distance brake pads move per one mm of cable pulled, the higher mechanical advantage.

V-brakes, road calipers and disc calipers have fixed leverage, while cantilever brakes allow change of mechanical advantage by altering the top cable length and angle. This allows user to choose more mechanical advantage, or less, but with more pads movement (for better clearance in mud).

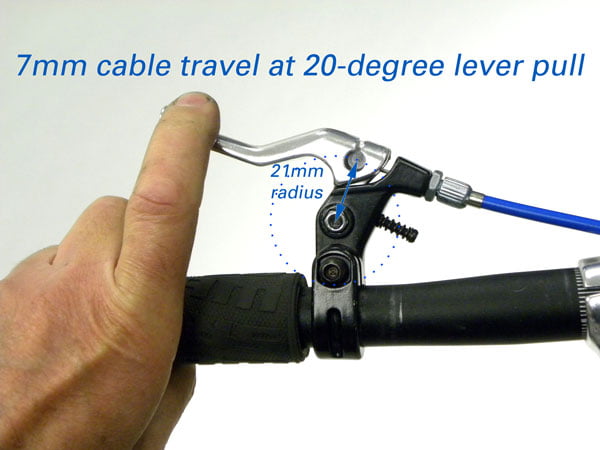

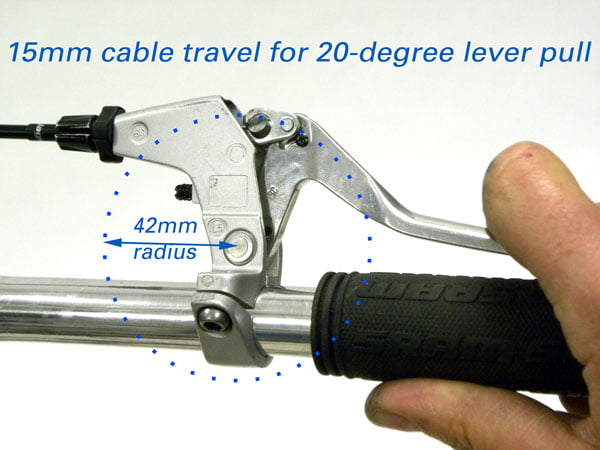

It is similar with brake levers. In the pictures below, there are two levers, both with 20 degree travel. One pulls 7 mm of cable, the other 15 mm:

So there is less cable pulled, just 7 mm for a 20 degree lever rotation – providing higher mechanical advantage.

There is more cable pulled, 15 mm for a 20 degree lever rotation – thus providing lower mechanical advantage.

3. Feel vs function

Too little mechanical advantage leads to low braking force. The feel on the lever will be firm, but this feeling is misleading. When trying to brake hard with such brakes, the force applied to the brakes will be relatively small, inadequate for effective stopping.

Too much mechanical advantage leads to a mushy, spongy feeling at the lever, since great force squishes both pads and cable housing. Braking force would have been great if the pads would touch and rub the rim/brake disc rotor all the time. Since pads are always at least 1 mm away from the braking surface, too much mechanical advantage results in lever being pulled all the way to the bars and brake pads just reaching the rim, not applying any force, or not even reaching the rim.

This is why mechanical advantage needs to be balanced. The amount of cable pulled by the lever needs to match the movement of brake pads. If the brake lever pulls 10 mm of cable, the brake pads should move about 5 mm, which makes for about 2:1 mechanical advantage.

4. Types of levers and brakes

There are three types of brake levers: V-brake, cantilever, and road levers. They match appropriate brakes with the same name. Mechanical disc calipers for MTB work with V-brake levers. There are also specially made road bike disc calipers that work with road brake levers and won’t work well with others.

There are also several types of modern road brake calipers with different cable pull ratios (and mechanical advantage). Shimano has SLR and Super SLR standards, recommending to match brake calipers and levers to the same standard. However, differences in cable pull are not large enough to significantly affect functioning and stopping power.

Compatibility and matching various levers and calipers is explained in this post: Bicycle brake compatibility.

5. Video – Brakes 101

I’ve made a video explaining and demonstrating the basic stuff related to brakes (in general, not just bicycle brakes):

https://www.bikegremlin.com/3497/brakes-101/

Last updated:

Originally published:

Hello, I read briefly your article months ago. I re-discovered and understood it very well using this article to explain the difference on different brake lever on reddit [https://www.reddit.com/r/bikewrench/comments/q9u2bj/comment/hgywrzq/?utm_source=share&utm_medium=web2x&context=3].

Thanks again for your mechanical insight uniques and profound.

Have a good day!

Absolutely fantastic read. I learned a lot!!

THANK YOU very much for your expertise!