An SEO expert picks up a socket wrench, socket spanner, ratchet, Gedore… 🙂

Dad jokes aside, in this article, after a brief introduction, I’ll briefly list the most common square drive ratchet (as I’ll call them) size standards and explain what each is best suited for.

In a separate article, I’ve explained the hex-bit size standards.

1. Introduction

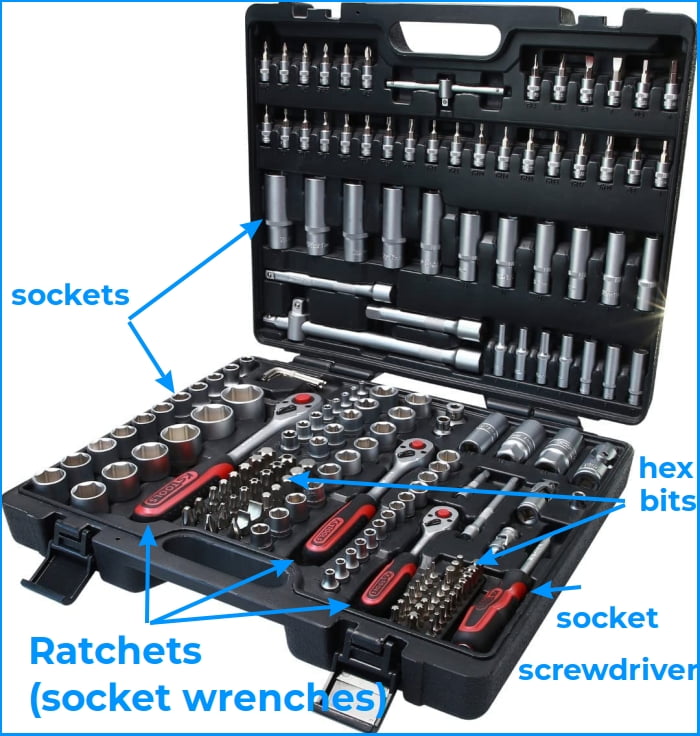

These tools can speed up work and help a lot when using sockets.

(I’m using a set like that one, and here is the Amazon.de affiliate shopping link)

Picture 1

In my country, “this tool” is often called “Gedore,” after a well-known German tool manufacturer (no longer as good as it used to be, especially their red tool series). The technically correct term is “socket spanner” (or a “socket wrench” if you’re in the US), but most mechanics will just ask for a “ratchet.”

There are ratcheting spanners/wrenches, but that’s a different tool. When you hear/read just “ratchet,” it refers to this tool – i.e. the socket spanner.

They usually come with a square, male socket driver (attachment system), though there are some exotic models with a hexagonal female driver (suitable for holding bits) and models with a hole that require special sockets (“pass-thru ratchets” – practical for screwing nuts onto very long screws, so you never hit against the socket’s bottom as it’s all hollow).

Picture 2

In this article, I’ll discuss the sizing standards of these square driver ratchets. Before that, I mustn’t forget to explain the main thing:

Ratchets let you turn a screw by moving your hand left-right without taking the socket off the screw. This is achieved using a ratcheting mechanism that locks in one direction while letting you turn freely in the opposite direction. There is a switch to choose whether you want to use the ratchet to tighten or loosen a screw.

Picture 3

2. Size does matter

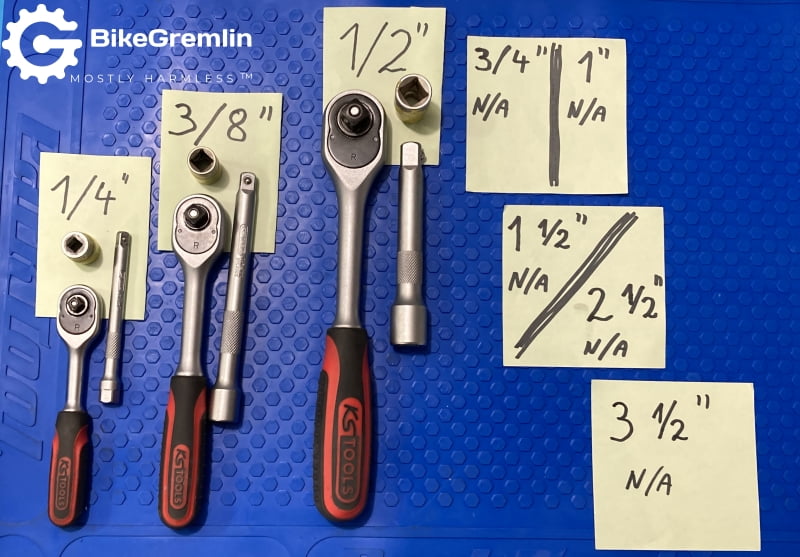

I’ll list the standard ratchet sizes (measured by the width of the square socket driver) and then explain what kinds of jobs each size is optimal for.

The nominal sizes are given in inches, and here’s a short list (if I’ve missed any, please use the comment section at the bottom):

- 1/4″ (6.35 mm)

- 3/8″ (9.525 mm)

- 1/2″ (12.7 mm)

- 3/4″ (19.05 mm)

- 1″ (25.4 mm)

- 1 1/2″ (38.1 mm)

- 2 1/2″ (63.5 mm)

- 3 1/2″ (88.9 mm)

The different sizes are there for a reason. Let’s see:

2.1. 1/4″

The smallest ratchets. They let you work fast and easily get into many tight spaces.

Of course, they offer relatively low torques, both because of the tiny mechanism and the relatively thin socket attachment – both can be easily torn if you apply too much torque (I have managed to do that, I must admit).

2.2. 3/8″

I’d call this the “golden middle ground.” Not as weak as the 1/4″, but not too big and bulky like the 1/2″ and larger ratchets.

There are adapters that let you use 1/4″ and 1/2″ sockets with the 3/8″ (use the 1/2″ sockets with great care, so you don’t break your ratchet by using too much torque).

If you can only afford one ratchet, I’d recommend starting with this size for most general small repairs – home, bicycle, motorcycle etc.

2.3. 1/2″

Larger, bulkier, but still not too large. It allows for greater torques and tightening of mid-sized and larger bolts.

Adapters for using smaller (3/8″) or larger (3/4″) ratchet sockets are available.

If you can only afford one ratchet size and you mainly work on cars and other “larger” stuff, I’d recommend this ratchet size.

2.4. 3/4″

They usually come with a relatively long handle (for good leverage) and are best suited for working on cars, trucks, and other heavy machinery.

For general fixes and repairs, including working on cars, you can get away without using a ratchet of this size (most of the time, at least).

I would not recommend this to start with, but if you need it more than a few times, of course it’s worth buying.

2.5. 1″, 1 1/2″, 2 1/2″, 3 1/2″

1″ and larger ratchets are used for huge bolts and tightening torques.

At this size, one is very likely to rely on electric or hydraulic power tools instead of using a wrench.

3. Recommended socket sizes for each ratchet size

First a note regarding the tightening torques:

- Be careful when using adapters to mount larger sockets (for example, using an adaptor to mount a 3/8″ 21 mm socket on a 1/4″ ratchet). If you use too much torque, you could break the ratchet’s mechanism or even its attachment “square.”

- Be also careful if using a small socket on a larger ratchet. Ratchet levers are sized to match torques “most commonly” used with socket sizes used with the ratchet’s square drive size. So, if you are using a 3/8″ ratchet to tighten a 6 mm nut, make sure to hold the ratchet near its “head,” to avoid overtightening the nut and stripping the threads.

Now, I’ll list the recommended size ranges of sockets and bits for each ratchet size. With a note that, when I say “Phillips 2” size, that also refers to other cross-tipped bits (Pozidriv, Supadriv, JIS etc.). The same goes for the Torx, Torx Plus and other similar bits.

I’m using the metric system, but the same applies to the similarly-sized imperial sockets and bits.

| Ratchet size | Phillips | Hex. (mm) | Torx | Socket (mm) |

|---|---|---|---|---|

| 1/4″ | <= 2 | <= 6 | <= 30 | <= 13 |

| 3/8″ | 2 ~ 4 | 3 ~ 10 | 15 ~ 50 | 6 ~ 24 |

| 1/2″ | 3 ~ 4 | 7 ~ 14 | 40 ~ 70 | 13 ~ 30 |

| 3/4″ | 4 | 10 > | 60 > | 22 ~ 60 |

| 1″ and larger | 4 | 14 > | 70 > | 36 > |

Table 1

This chart is relatively conservative. For example, I regularly use a 32 mm socket with my 1/2″ ratchet – but I generally don’t use it for torques over 150 Nm. Nonetheless, it’s easiest to work with sockets and bits that “match” the ratchet’s size so to speak.

This leads us to the torque recommendations – so here’s a list of recommended torque ranges for each ratchet size:

3.1. Recommended tightening torques per ratchet size

| Ratchet size | Torque range |

|---|---|

| 1/4″ | <= 20 Nm <= 15 ft-lbs |

| 3/8″ | 10 ~ 80 Nm 7 ~ 60 ft-lbs |

| 1/2″ | 20 ~ 200 Nm 15 ~ 150 ft-lbs |

| 3/4″ | 40 ~ 700 Nm 30 ~ 515 ft-lbs |

| 1″ and larger | 80 ~ 1000+ Nm 60 ~ 740+ ft-lbs |

Table 2

This chart is conservative too. High-quality ratchets will easily take over double the max. specified torque in the table (per ratchet size).

The same goes for the minimum torque. I regularly use a 3/8″ ratchet to tighten 5 Nm bolts, but I hold it near its head (nowhere near the end of its handle) and use some caution.

It’s best when you use a matching ratchet size for a given torque, as its handle length is designed to support the designed torque range.

4. Final notes

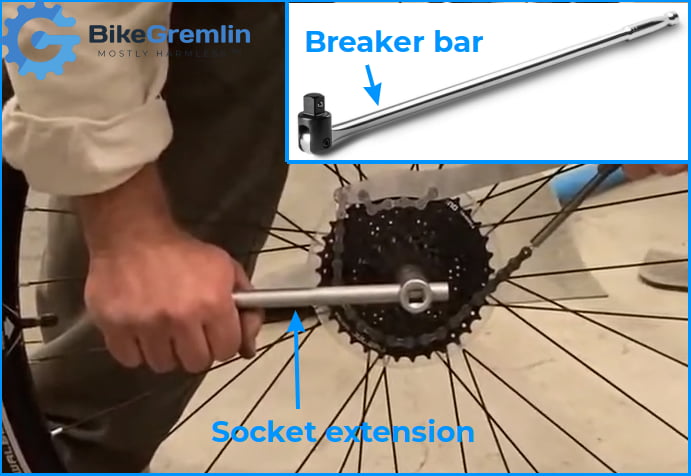

Don’t use ratchets to loosen stuck bolts.

You’ll damage the mechanism and destroy the tool.

Use a breaker bar or a T-handle for that:

Picture 4

Good ratchets need a bit of love and care to serve us well:

5. Ratchet set recommendations

I’m very sceptical when it comes to Internet reviews, customer ratings etc. I’ve seen people praise tools that I know are bad or criticise tools that have served me very well.

So, I tend to rely on my own, first-hand experience. When shopping, I do consult with mechanics I trust, but I use that just to narrow down the choice of tools I’m looking to buy – the final verdict and my recommendation is either from my own experience or by noting the mechanic who recommends it (in case someone asks and I haven’t tested it personally).

So, I can recommend KS Tools 917.0779 (German Amazon affiliate link).

For the readers living on the wrong side of the ocean, 🙂 this is the closest matching set I could find on the US Amazon (affiliate link): KS Tools 917.0795.

This is a decent-quality set which has served me for about 10 years and cost about $100.

It comes with three ratchet sizes: 1/4″, 3/8″, and 1/2″ – which covers most work around the houses or cars.

The set of adapters and sockets that come in the box are very good – including the deep sockets, as well as sockets with rubber for holding petrol engine spark plugs in place.

What I find lacking is a 3/8″ socket to 1/4″ hex-bit holder adapter, for when I need to apply a bit more torque with a Torx 40-bit or similar (when the 1/4″ ratchet is at its limit, and a 1/2″ can not approach/fit always, depending on the job).

I also wish the set included two more longer T-handles (a 3/8″ and a 1/2″).

The case itself does not hold the sockets in place very well and its hinges are very weak. So, for any fieldwork, I carry it like a baby – lying it horizontally on top of my arms. Highly impractical!

Finally, the set of bits is quite limited – but that’s not something I expect to have a lot of in a ratchet set anyway, I get those separately (do get some high-quality bits from Wera for the screws you often turn with a ratchet).

Note that the ratchets do have a bit more play than I like, but until I test some roughly ten times more expensive sets, I can’t say how robust and durable those “finer” sets are. It’s also important to note that the play doesn’t seem to increase over time – and the tools work great in practice.

Briefly: the price-to-quality ratio is excellent, and it will equip you to get most jobs done, but it’s not a top-quality product.

In the meantime, I’ve also ordered Wera Bicycle Set 7 (Amazon affiliate link).

Briefly put: it’s not bad, but it’s very expensive. Until I see how it holds up after a few years of use, I can’t recommend it.

Here is my video with the Wera Zyklop ratchet – Bicyle Set 7 review.

It cost an arm and a leg – about $130 for the small set.

What I like about it is that I’m very pleased with Wera’s bit quality, and it comes with practically all socket and bit sizes I use when wrenching bicycles. Also, the 3/8″ ratchet is big enough for most bicycle-related torques, without being needlessly large.

This set looks as if Wera asked a bike mechanic about the bit assortment they would like (the 15 mm socket coming in a deep version tells a lot).

The ratchet’s head can be swivelled to stay in line with the tool, so you can use it as a big screwdriver. This could help reduce the probability of overtightening smaller screws (with bicycles, would probably not fit every car job in that orientation). The downside is that the head is bulkier compared to a “classic” ratchet. If you are working in a tight place that doesn’t allow you to mount some adapters & extenders, this can be a problem (with bicycles, motorcycles and most in-house repairs, this is not an issue).

Ratchet’s mechanism quality itself doesn’t look noticeably better than the above-described KS Tools set. Bits are a bit higher quality, but the sockets started flaking and leaving silvery residue on the ratchet upon the very first mounting. That doesn’t look promising.

Colour coding is nonsense. For example, the 10 mm hex key in the set is marked with blue, and the 10 mm socket is marked with yellow?!? What kind of logic is that?!

The bag is very practical for fieldwork. Soft, and compact. The socket attachment system requires you to rotate a socket by some 90-ish degrees before pulling it out. This works great in practice, making it easy to take, and return sockets (and lock them back in place securely & positively). The poor quality case is my main complaint with the KS Tools set. This Wera kit, on the other hand, fits easily in my backpack or in a bicycle pannier, so I can haul it wherever, without any worries of losing any bits or breaking the case.

So, my first impressions are: so-so. In a couple of years, I’ll know how it holds up to daily use. If it holds up, I might recommend it for fieldwork, for those who primarily work with bicycles.

Last updated:

Originally published: