When I’m shopping for hex-bits and bit-holders or screwdrivers online, it is vital to get the right type and size for the job. In my experience, even many experienced mechanics are not familiar with all the sizes and standards. That’s why I’ll dare to say that the image above is worth a million dollars. 🙂 Below, I’ll explain it all in more detail. I’ll even recommend some good-quality bits and bit-screwdrivers, using affiliate links (though I recommend you buy in your local hardware stores – it’s good to support them and have them around).

In separate articles, I’ve explained the difference between Phillips, JIS, Pozidriv, and Supadriv screws and screwdrivers, as well as the square drive socket wrench (ratchet) size standards and recommended torques per each size.

TL/DR

Hex bits are practical and awesome. 🙂 Here, I’ve explained:

- Which bit size standards exist (if you come across a very small or a very big bit and aren’t sure which driver to use, or vice-versa)?

- What kinds of bits exist (mounting interface, length, impact-rated, etc.)?

- Buying advice (what’s worked for me).

1. Hex-bit standard sizes

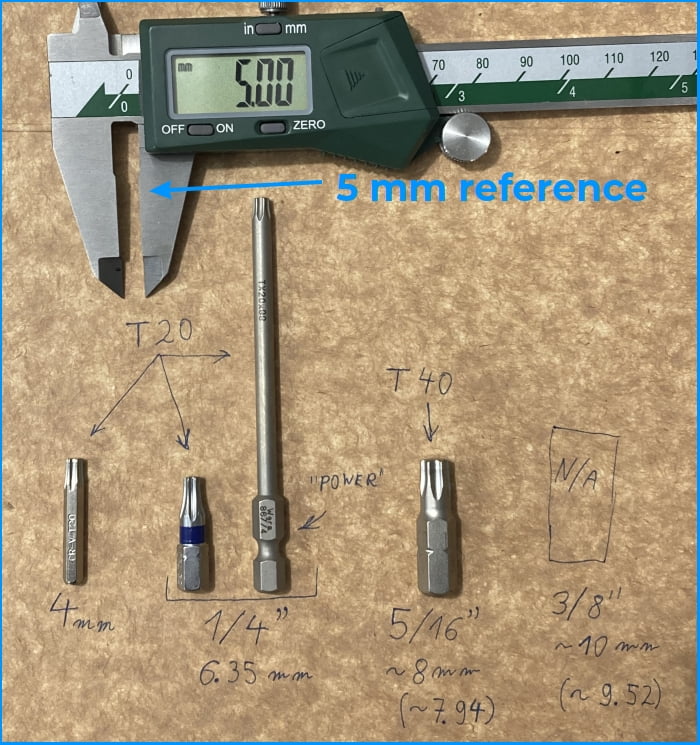

A picture speaks more than a thousand words:

4 mm; 1/4″; 5/16″; 3/8″

Picture 1

The calliper at the top of picture 1 is set to 5 mm to give you some size perspective (and no, I don’t have any 3/8″ bits in my workshop).

So, there are four standard bit (and bit driver and screwdriver) sizes, generally aimed for the following uses:

- 4 mm (the only one with a metric nominal size) – delicate and precise

Used for delicate electronics and very fine mechanics – watches, laptops etc.

Fine, “watchmaker” bit-screwdrivers often come with a holder for this size. - 1/4″ (6.35 mm) – the golden middle ground

Probably the most widely-used standard. Screws for wood and screws for computers, bicycles, and many screws on cars and motorcycles can be screwed out and in using bits of this size.

Used with both screwdrivers and electric (cordless, battery) tools. - 5/16″ (about 8 mm, more precisely about 7.94 mm) – hard & heavy

Used for large and mid-sized screws and bolts on cars, motorcycles, machinery etc.

These are often used with electric or pneumatic power tools, or a bit-driver mounted on a 1/2″ or a 3/8″ ratchet, as the torques generally exceed what a human can achieve using a screwdriver. - 3/8″ (about 10 mm, more precisely about 9.52) – heavy machinery

Serious heavy machinery, often with Torx interface bolts (capable of transferring huge amounts of torque without striping).

Turned using electric or pneumatic power tools, or ratchets sized 1/2″, 3/4″ or 1″.

Picture 2

Why is this important?

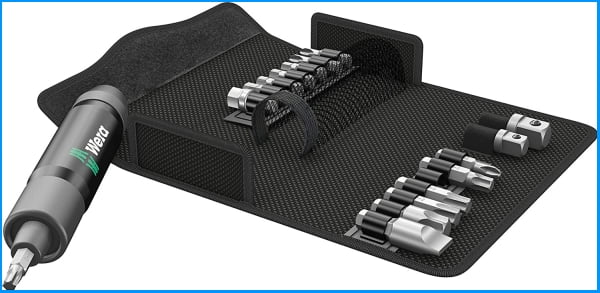

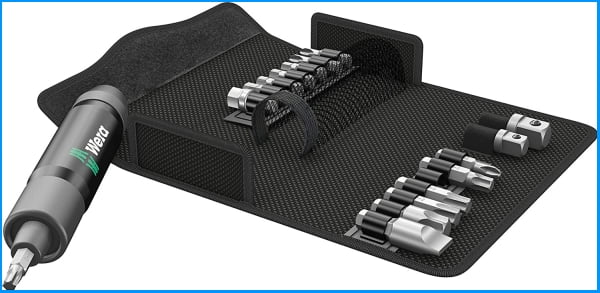

Here’s a practical example. I’m looking for an impact screwdriver for bicycle servicing (and smaller screws that get stuck, in general). There are two products by the same company, Wera:

(Amazon affiliate link)

Picture 3

This impact screwdriver can achieve up to 90 Nm of torque, but it only takes 5/16″ bit sizes, while all my 4 mm hex (Allen) bits are designed for 1/4″ hex-bit drivers (and it’s difficult for me to source 4 mm Allen bits with a 5/16″ drive standard).

Yes, there are all sorts of adapters, but for this use (high torque with hammer hits), I don’t like the idea of stacking any adapters unless it’s absolutely necessary. So, I found and bought something more suitable:

(Amazon affiliate link)

Picture 4

This impact screwdriver takes 1/4″ sized bits. It provides up to 25 Nm of torque, which is a lot less than 90 Nm that the model above provides, but sufficient for the sizes and diameters of bolts unscrewed with 1/4″ size bits.

On the other hand, this impact screwdriver isn’t very good for many automobile screws, and for that, I still must borrow a 5/16″ impact screwdriver from my neighbour Lucky (until I buy one). 🙂

Alas, our story about bits doesn’t end here – read on.

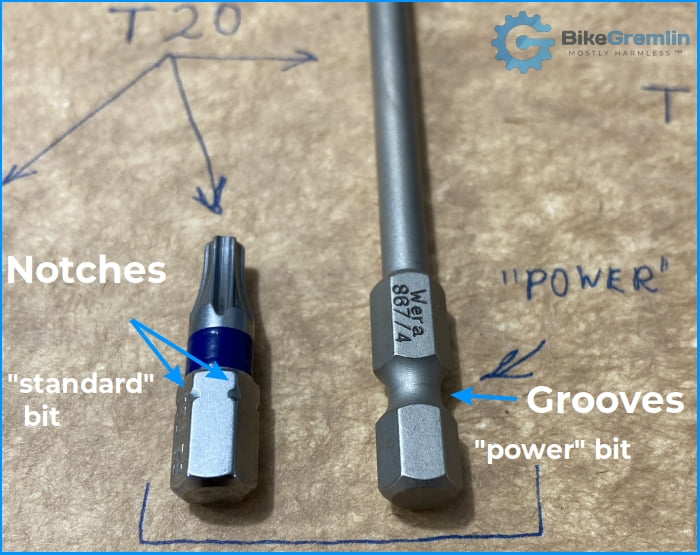

2. Grooves (power bits) vs notches (“standard” bits)

(bit attachment interface shape)

This title might sound a bit complicated, but there are only two (as far as I know):

Picture 5

- The bit on the left is called “standard.” It comes with or without snap-ring notches.

- The bit on the right is called the “power” bit and comes with a groove.

I’ll explain what the catch is in a bit (pun intended 🙂 )

Notches (the bit on the left) and grooves (the bit on the right) are used to lock the bits in place in drivers that provide mechanical locking of bits (some drivers just use magnets to hold the bits in place).

“Power” bits were designed for use in electric and pneumatic impact screwdrivers. The narrow groove provides flexibility (easier twisting) which absorbs shocks (abrupt impact) to the bit or the screw – to a degree (just enough to prevent snapping, but not enough to negate them and thus make the use of impact tools pointless).

Simultaneously, the groove allows for locking the bit securely in place using a system of steel balls.

High-quality bits sometimes sort of “bite” into a screw. If they are held onto by a magnet only, when you remove the screwdriver, the bit can fall out. This can be frustrating, especially if the bit doesn’t remain stuck in the screw, but bounces somewhere on the workshop floor.

However, today many manufacturers use the same mould to create “power” bits that aren’t strong enough to be used in impact power tools. They have the shape but not the material strength (just like Italian motorcycles 🙂 ).

So, when shopping for bits to use with power tools, check the manufacturer’s specifications, and don’t rely on the bits’ shape alone!

3. Impact-rated vs “ordinary”

(bit types based on the intended use)

There are two and a half types of bits based on their intended use: 🙂

- Ordinary bits (non-impact-rated).

- Impact-rated bits.

These have a sub-group, as I’ll explain later

The ordinary (non-impact-rated) bits are harder and stiffer but more brittle. So they are better at resisting wear, but if you use a strong impact power tool, they could snap off at the first go. Also, being stiffer, they transfer more of the tool’s impacts to the screw, increasing the probability of the screw’s head breaking off. Apparently, screws don’t really like being hit with a hammer.

Electric and pneumatic impact screwdrivers achieve higher torque by making a lot of short hammer-like impacts. This allows you to put huge amounts of torque onto screws without being as strong as a bull to hold the tool from spinning in your hand. But those impacts are also a downside. Impact-rated bits are more flexible, and they usually come with the “power-bit” mounting shape, which increases their flexibility. This makes the bits act as a sort of suspension, making both the bits and the screws less susceptible to breaking from the impacts.

The downside is that impact-rated bits are a bit softer and more flexible, and they will wear out faster, but are more resistant to breaking when used in impact power tools and are less likely to damage screws via the strong impacts. These bits too will eventually fail if used in impact power tools, but they generally last longer than ordinary bits when used with such tools. They are usually black/dark – but always check the manufacturer’s specs to confirm.

There is another catch. A softer (less brittle) bit will have its tip wear out faster. This can cause problems with cross-tipped screws especially – making it a lot more likely to cam out. When a bit’s tip cams out while tightening a screw at high speed, the screw’s head too will get damaged and worn, rendering it useless.

Yet an extra caveat are the impact-rated bits designed for use in screwdrivers for removing stuck bolts (as shown in pictures 3 and 4).

Bits for these tools often don’t have the “power bit” shape. The idea is not to make them too flexible since they are used when all else fails and should transfer the torque from a hammer hitting the screwdriver’s head (I should make a separate article or a video about these tools).

The bottom line is: a bit’s attachment shape itself (chapter 2) doesn’t mean that a bit is impact-rated, and you should check the manufacturer’s specifications.

4. Bit length

In my experience, bits start from the following lengths:

- 4 mm and 1/4″ sized bits start from 25 mm (about 1″).

- 5/16″ and 3/8″ sized bits start from 30 mm.

Yes, you might run into a bit half that length, but that’s what I’d call “exotic” and quite difficult to source and come across.

When it comes to longer bits, I’m not sure if there is a standard, but for bits of 1/4″ and larger, I came across 30, 50, 70 and 90 mm lengths.

Longer bits can help in some situations (tight spots and similar), but generally, it’s best when a bit is as short as it fits for a given job. An exception to this rule are screwdrivers with bit driver placed close to the handle. Those are nice to use with longer bits.

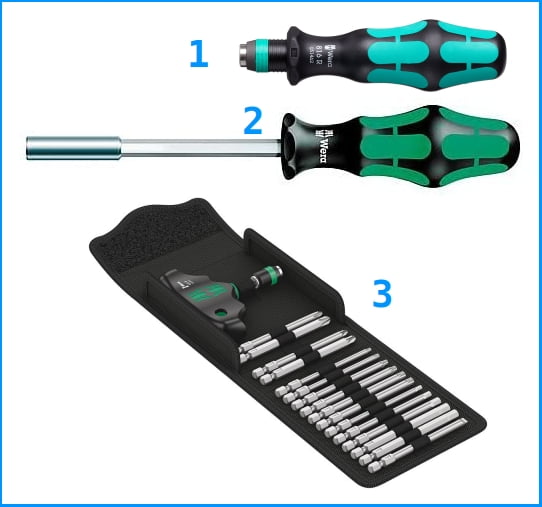

1 – short-blade bit screwdriver, longer bits are a better option with this one.

2 – long-bladed bit screwdriver, shorter bits are more convenient to use with it.

3 – T-handle bit holder with a short blade, already packed with some long bits.

Picture 6

Note:

For the smaller bit sizes (4 mm and 1/4″), you will more often encounter small screws inside narrow recesses – so if your bits aren’t long enough, your bit holder (screwdriver) won’t fit through that, despite its blade length. That’s why I defined the optimal length as “the shortest suitable for a given job.” Any extra length beyond what’s needed increases wobbling and the chance of a screwdriver tip cam-out.

5. High-quality bits and bit-screwdrivers

I’ll be updating this chapter over time as I try and test different tools. It’s a work in progress, i.e. “what’s worked well for me so far.” And yes, I will be using Amazon affiliate links, but I suggest you support your local hardware store (and you can always support my work via a Patreon donation 🙂 ).

5.1. 4 mm bits – for fine electronics and mechanics

The 4 mm size, also known as: “Hey, this bit is loose, it’s smaller than my 1/4 inch bits!?!” 🙂

For this, I’m currently using a cheap Chinese set with all the bit tip types that I need. Unfortunately, neither the screwdriver nor the bits are of exceptional quality, so I’m looking forward to your recommendations and suggestions. I’d love to spend less than $100 if possible, the bits to be as narrow as it’s required by their tip sizes, and 40+ mm long if possible.

Update, June 2023:

I bought iFixit Pro Tech Toolkit (Amazon affiliate link). It’s very good. I’m happy with it and I can recommend it.

5.2. 1/4″ bits (6.35 mm) – the golden middle ground

I’m very pleased with Wera bits and bit-screwdrivers. I often use these two sets:

(Amazon affiliate link)

This set comes with most bits I need to use when fixing bicycles – it’s a pretty neat selection. The screwdriver is on the small side, which often suits me perfectly.

Note:

Phillips 1 size bit (and other smaller head bits) have their shaft wider than it must be. This makes them stronger, but also impossible to use with bolts recessed in narrow holes deeper than 1 cm. A shame.

This set nicely completes the previous one. I got some larger bits and some Pozidrive bits, while the bits I use most often (and which will most quickly wear out) are practically doubled (exist in both sets). The T-handle is nice for when I need to use more torque, while it can also be spun very quickly using its shaft.

For the more exotic bit types, I use my old Metabo bit set. New Metabo is no longer up to that quality, so I can’t recommend it. While Wera bit sets cost an arm and a leg. I’ll have to figure that out once the old Metabo gets worn.

5.3. 5/16″ bits (~ 8 mm) – hard & heavy

The 5/16 inch bit size, also known as: “Hey, this is larger than my ‘standard” 1/4 inch bit!?” 🙂

When I need these larger bits, I use the ones from my KStools ratchet set. Mine is over 10 years old and serves me well. The new one is available on German Amazon, but its socket eject buttons are made of plastic, not steel (as is the case with my set). I don’t know if it’s as good now.

(Amazon.de affiliate link)

5.4. 3/8″ bits (~10 mm) – heavy machinery

I don’t use these bits, so I can’t recommend any.

I’m sure that you can find a freelancer “content writer” on Fiverr who’ll write a “10 best 3/8″ bit sets” article for ten bucks, but I’m not one of those.

6. Conclusion

I hope this article has helped you at least a bit to grasp this topic and avoid mistakes when buying tools.

I did not address any details related to bit materials (S2 steel VS Chrome-Vanadium and similar). That is beyond the scope of this article (it’s too long already). Perhaps some other time – when I find the time. Though I would prefer to see that tackled by a mechanical engineer employed in the industry – I’d be delighted to help with writing such an article, for free.

7. Video about screwdrivers and bit drivers

Last updated:

Originally published:

This is great, thanks