This post explains cantilever brake adjustment.

Table Of Contents (T.O.C.):

- Intro

- Cantilever brake geometry – basic terms

- Types of cantilever brakes

- Mechanical advantage of cantilever brakes

- Cantilever brake adjustment

4.1. Caliper angle adjustment

4.2. Adjustment of yoke angle

4.3. How does it all work in real life?

4.4. Correlation of adjustments

0. Intro

Cantilever brakes are unjustly considered to be poor brakes by many cyclists, compared to V-brakes for example. They do have their flaws, but low braking power is not one of those, it is mostly due to poor pad/rim material, and (more often) due to poor adjustment. Cantilever brakes allow the user to choose between stronger braking force, or shorter brake lever travel with weaker braking force. In short, these brakes have adjustable mechanical advantage, which is explained in this post:

Bicycle mechanical brakes – working principle.

1. Cantilever brake geometry – basic terms

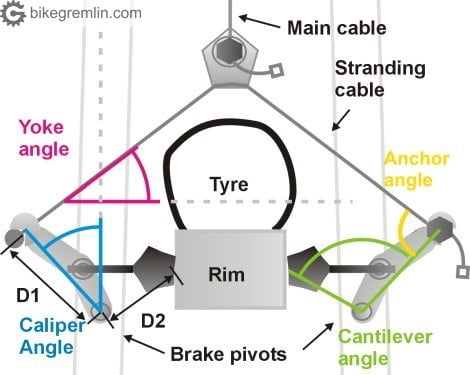

Picture 1

- Yoke angle: angle that stranding cable takes from horizontal.

- Caliper angle: angle that brake arm takes from vertical (line from pivot to cable anchor is taken for measurement), at the point when pad touches the rim.

- Cantilever angle: angle between the brake shoe – brake pivot line (D2) and the brake pivot – cable anchor point line (D1).

- Caliper length: ratio of D1 to D2 lengths (how much longer is the brake caliper arm compared to the distance of brake pad from the pivot).

- Anchor angle: angle that brake arm takes to the stranding cable, at the point when pad touches the rim.

2. Types of cantilever brakes

- Wide profile: cantilever angle is greater than 90 degrees. Obsolete standard. Has low mechanical advantage and requires brake levers with a high mechanical advantage.

- Medium profile: cantilever angle around 90 degrees. Most MTBs from late 80s and early 90s have such calipers.

- Low profile: cantilever angle below 90 degrees. The main advantage is these brake arms don’t stick out so much, so they don’t catch things (tree branches, or rider’s heels for the rear ones). If not set up properly, these brakes offer good firm feel on a work-stand, but low braking power – that’s why they require special attention when adjusting.

3. Mechanical advantage of cantilever brakes

Three factors affect mechanical advantage of a cantilever brake system:

- Brake levers. Lever mechanical advantage depends on the amount of cable pulled and the lever length (distance between the lever pivot and the place where rider pulls on the lever). It is usually around 3.5. For V-brake levers it is around 2.

- Ratio between caliper arm length and distance of the pad from anchor point (D1:D2). This mechanical advantage usually is between 1 and 2.

- Anchor angle – gives mechanical advantage when it is 90 degrees. The further away from that it gets, the less it contributes.

- The main effect on mechanical advantage, especially with low profile cantis, comes from adjusting stranding cable, which effectively alters the yoke angle. The smaller the yoke angle, the more mechanical advantage a brake has, but pads travel less for the same amount of brake lever movement.

The aggregate effect of all the noted factors determines the total mechanical advantage. First factor is determined by lever choice. Second is (mostly) determined by brake caliper choice. The rest can be altered by brake adjustment and this will be explained in the next chapter.

4. Cantilever brake adjustment

4.1. Caliper angle adjustment

Caliper angle of 90 degrees gives the least mechanical advantage. As the angle narrows, mechanical advantage rises, but pads move less for the same brake lever travel. Up to a point when the advantage starts diminishing, along with decreased pad movement! To make this as close to 90 as possible, with narrow profile brakes the pads should stick towards the rim as much as possible, to make the cable anchors stick out as much as possible. Of course, pads mustn’t be too far from the rim, since the effective angle is the one at which pads touch the rim. It is the opposite for decreasing the angle – pads should stick out towards the rim as little as possible.

Available range of angles depends on caliper type, as shown in the pictures below.

4.2. Adjustment of yoke angle

The smaler the yoke angle, the greater mechanical advantage. However, yoke angle of zero would mean the cable passing through the wheel. So the minimal possible yoke angle is one that allows the straddling cable to clear the rim, tyre, mudguards etc.

Yoke angle adjustment has the greatest impact on mechanical advantage of cantilever brakes. Overdoing this can cause problems. Too much mechanical advantage can lead to brake lever bottoming out against the handlebars, before any significant brake force is applied – levers have a limited range of motion. Likewise, too little mechanical advantage leads to weak brake force.

4.3. How does it all work in real life?

Brake pad distance can be adjusted on most cantilever models. Brake pad distance affects the cantilever angle, caliper angle and caliper length ratio. This is especially important for low profile brakes.

Cantilever angle is rather small with low profile brakes and as the pads wear down, the caliper angle diminishes more drastically, lowering mechanical advantage exponentially. That is why it is good to set low profile brake pads as close to the rim as possible, in order to make the caliper angle as large as possible and yoke angle as small as possible (without the cable rubbing the tyre). In addition, since these brakes have low mechanical advantage, lowering yoke angle will give optimal mechanical advantage – without making it too much (too much mechanical advantage would make the brake levers travel all the way to the bars, without pads reaching the rim).

For wide profile brakes, it is the other way round. Because of the caliper angle, low yoke angle can give too much mechanical advantage. That means too much brake lever travel before the pads even reach the rims. This should be considered when setting up these brakes.

Medium profile brakes are somewhere in between the two extremes.

4.4. Correlation of adjustments

Changing pad distance from the pivots (moving them closer, or further from the brake caliper arms) effectively changes both cantilever and caliper angle. This is the first thing that should be set up, according to the type (profile) of cantilever brakes used.

After the caliper angle has been set, yoke angle is adjusted by placing one stranding cable end in one side of the calipers, passing it over the hook that is attached on the main cable, then pinching it at the opposite side of the calipers, at the desired length (with models that allow for this adjustment, some have a fixed stranding cable length).

Shorter stranding cable will have a smaller yoke angle, and will require that the hook attached to the main cable be put lower (and longer main cable). Vice versa for longer stranding cable.

As a brake lever is pulled, harder for hard braking, several things happen:

- Pads start moving towards the rim.

- Calipers rotate towards the rim, making the caliper angle narrower.

- Yoke angle increases.

While the effect of greater yoke angle always decreases mechanical advantage, the effect of caliper angle change depends on particular achieved angle and angle change. This can be determined only when tested, feel on the stand can be deceiving. That is why cantilever setup takes some trial and error, and experience can help get it right in less time.

Shimano cantilever brakes of decent quality (clicking on the image below leads to the Amazon on-line shopping – as an Amazon Associate I earn from qualifying purchases):

Last updated:

Originally published:

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/cantilever-brake-adjustment-article-comments.144/

Hey there Relja, first off, this post is great! It has all more information than I have been able to find anywhere else after days of scouring the internet.

Some potentially helpful backgound info before I ask my question: I run Tektro Oryx 99A brakes. They came with the used 2014 bike I bought in summer 2018. They have slowly been decreasing in breaking quality since I got the bike and my bike shop hasn’t been a ton of help as the guys I have talked to simply don’t work on cantis much. I have been reading users manuals and manufacturer’s instructions, in addition to watching Park Tool and GCN tutorial videos for canti adjustments/tuning and haven’t been able to find the info I am seeking.

I have tried adjusting my cable tension, spring tension, and used all three of the holes for the spring base pin, but my front left canti still doesn’t have enough spring tension to come off of the rim after I release the lever. If I take the quick-release cable off of the canti, it springs off the rim immediately. It seems the spring tension has somehow been compromised, because no matter what combination of spring/cable tension I have tried, I still wind up with a left canti that can’t spring back against the force applied to it by the right canti spring and brake cable.

Do I need to just buy new cantilevers?

Can I replace the spring?

Am I missing an obvious adjustment?

I would greatly appreciate any advice you could offer and I am hoping that you still monitor this post! 🙏

Cheers,

-Ben

Hello Ben,

Several problems mentioned here. I’ll discuss them both.

1) Brake’s fading performance

Possible problem causes:

– Pad wear alters the angle, affecting mechanical advantage.

Adjustment should solve this one.

– Grease/dirt on the pads and rims.

Solution is cleaning the rims using 90+ % alcohol (here it’s available in those huge shops – super/hyper markets as they are called – rather cheaply).

And cleaning the pads with it, perhaps first grinding them using a file, or some sandpaper.

Kind of brake pads I recommend (similar models exist for V-brake types of brakes, it’s the 2-piece system that makes the difference).

2) One side of brake caliper not retracting

It happens only when the cable is attached – if I understood correctly.

That leads me to a conclusion that spring force on one side is a lot greater than on the opposite side. The brake model has screws for fine-tuning the spring tension.

Changing the hole where the spring is engaged in the frame (three holes usually) doesn’t help? Changing the hole makes a huge difference in spring’s tension. So if changing that doesn’t help either (a lot more coarse method than using the adjustment screws at the calipers), then I suspect one of the following:

– Dirty/stuck bushings.

Disassembling, cleaning, and greasing the mechanism could help.

– Damaged spring, or the inside of the caliper, the place that provides resistance to the spring (frame hole is one side, the other side is against the adjustment screw – that can get damaged/misaligned, so the spring is no longer held in tension on the inside).

– Spring loosing tension by a huge order of magnitude – least likely.

I hope this helps. Do let me know what you try and figure out.

Regards,

Relja

What a great post and dialog. Thank you very much. Given me lots of tuning advice.

Larger dia wheels are technically better. The penalty for larger wheel dia has always been the weight factor and greater moment of inertia. However with newer tech we have lighter weight alloy construction or even carbon. These new tech rims do not have to sustain brake wear since they use discs which are steel.

The result is a better bike with around the same overall weight as the older 26″.

Just like the older petrol vehicles are phasing out we will see a trend to larger dia bicycle wheels … but hopefully after my time.