Here, I’ve explained shifter and brake cable & housing standards. From my experience, many problems with poor shifting, or braking, come from using incorrect components. Separate post explains brake and shifter cable routing.

Table Of Contents (T.O.C.):

- Shifter (derailleur) cable standards – differences

- Brake cable standards – differences

- Shifter housing standards

- Brake housing standards

- IMPORTANT: difference between brake and shifter housing

- “Exotic” models

- My shopping recommendations

TL/DR

Using brake housing for shifters makes your shifting suck.

Using shifter housing for brakes is outright dangerous!

In this article, I’ve explained how to tell what is what, and gave some buying recommendations (from my decades of experience).

It’s not long – I just put many pictures to help you understand and see the differences. 🙂

1. Shifter (derailleur) cable standards – differences

Shifter cables have a barrel on one end, that is used for shifter to pull (and release) the cable, while the other end is soldered, so that wires don’t get unwinded and so that the cable can more easily be routed (and cut to the appropriate length after routing).

Picture 1

Shifter (derailleur) cables come in two standards, main difference being the end barrel, though cable thickness also tends to differ:

- Campagnolo standard – 1.1 to 1.2 mm cable diameter, with a bit smaller diameter barrel at the end

- Others (Shimano, SRAM…) – around 1.2 to 1.3 mm cable diameter – with end barrel a bit larger than Campagnolo one

Apart from the diameter, Campagnolo and Shimano shifter cables are visually almost identical, so pay attention to specifications when shopping (especially if you have Campagnolo shiters, since Shimano cables won’t fit Campagnolo shifters).

Picture 2

2. Brake cable standards – differences

To avoid/prevent any confusion, I’ll explain brake cables (and housing) as well in this post.

Brake cables come in three standards, with the main difference being the size and shape of the end barrel:

- MTB – with a large barrel on one end

- Road Shimano compatible – for Shimano and SRAM shifters

- Road Campagnolo

Picture 3

With road cables, Shimano ones have a bit larger barrel, though very similarly shaped. In fact, some manufacturers (like Jagwire, for all I know) make road bike brake cable ends such that barrels are a bit on the smaller side, hence the same model fits both Shimano and Campagnolo brake levers.

Source: bikehub.co.za forum

Picture 4

Cable thickness is about 1.5 to 1.6 mm, for both Shimano and Campagnolo.

3. Shifter housing standards

For shifter housing there are two standards:

- Shifter housing with 4 mm outer diameter.

- Shifter housing with 5 mm outer diameter (the same diameter, but not the same type, as brake housing).

All the shifter cables will run with no problems through housing by any of the above noted standards. Some MTB riders prefer 5 mm housing, since it leaves more room, so they don’t get stuck with mud that easily. Though, for 4 mm shifter housing, Shimano makes seals that prevent the entrance of dirt:

Picture 5

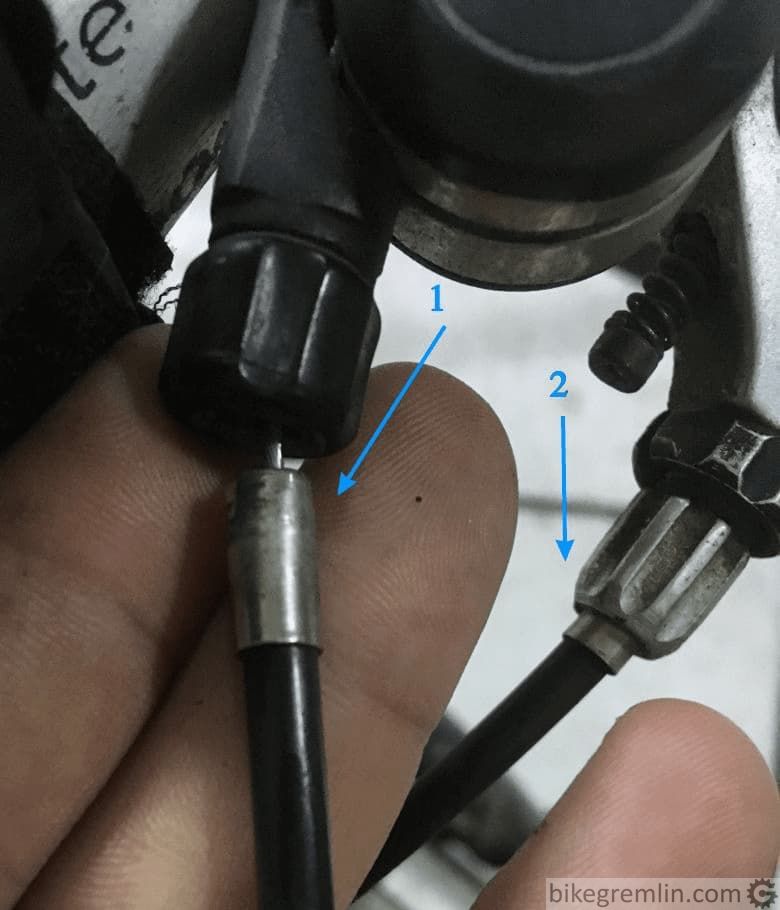

For 5 mm shifter housing ends, the same (metal) ends can be used as for brake housing (even though those are two different housing types!).

They look identical from the outside

Picture 6

Picture 7

Important note: Shimano seels (at least here, in Serbia) two shifter housing models:

- Shimano SP40 SIS. This one doesn’t work very well and I don’t know what it is good for. On the outside, it looks like the proper shifter housing: is only 4 mm wide (brake housing is usually 5 mm wide), and has SIS (Shimano Indexing System) written on it. But, it has a spiral steel “skeleton,” like the one used in brake housing – stronger, but more flexible.

- Shimano OT-SP41 SIS. This is the proper shifter housing. It is also 4 mm wide (outer diameter), but has the longitudinally lined steel wires, making it stiff in terms of shifter cable for-aft movement, resulting in more precise shifting. See picture 8 below for the difference between this, and brake housing “skeleton.”

SP40 does work a bit better with shifters, compared to brake housing (low-end bicycles sold locally often come with brake housing used for both brakes, and shifters). But it is still inferior to OT-SP41 in terms of shifter precision.

4. Brake housing standards

With bicycle brake housing standards there aren’t any differnces – they are all 5 mm outer diameter with steel end caps. Apart from hydraulic brake hoses, of course, but that’s a different matter.

5. IMPORTANT: difference between brake and shifter housing

Too often I see brake and shifter housing mixed. But this is not good, and can even be dangerous!

- Shifter housing is constructed to compress and elongate as little as possible with shifter cable tension change (while shifting up and down). But it can not take large force – pull cable strong enough and it will split!

- Brake housing is made to sustain very high cable tension forces without splitting, but slight compression is not as detrimental.

Left: brake housing with a woven strong steel spiral.

Right: shifter housing, with steel wires running along the housing length, to minimize compression and elongation changes.

Picture 8

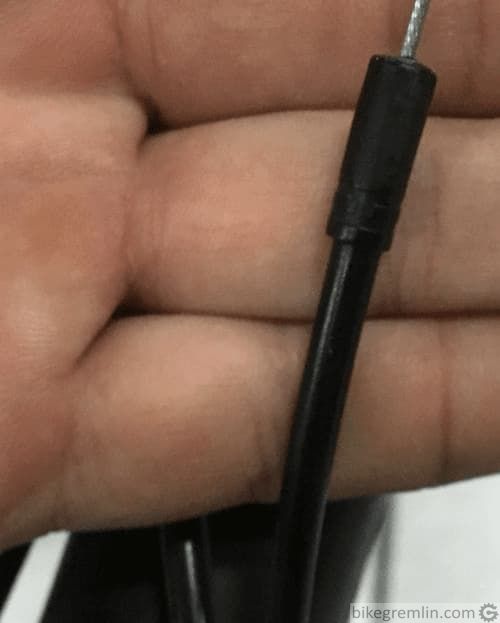

Right: shifter housing. Parallel steel wires prevent the housing from compressing (effectively changing length), but offer little resistance to high forces, so it can’t be used as a brake housing

Picture 9

Right: shifter housing, with parallel longitudinally placed steel wires.

They are easily discerned by looking from “the front”, but one needs to pay attention.

Picture 10

6. “Exotic” models

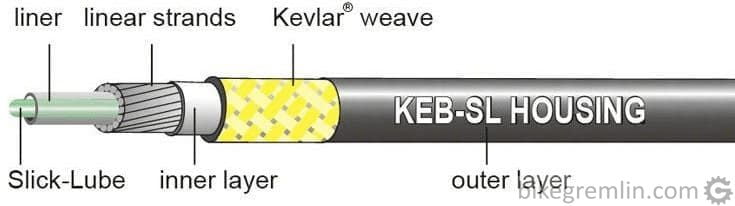

There are special, braided brake housings that compress a lot less than “ordinary” brake housing, which is good – leaves more lever play and allows for more precise brake modulation. They are usually constructed using a layered combination of longitudinal steel wires and spiral steel, or kevlar lining to give more strength, so the housing doesn’t split when high braking force is exerted.

Such housing, due to less compression, can also be used for shifters. Though, for shifters, it is still a bit better to use shifter housing.

Their main downsides are somewhat higher weight and a lot higher price.

Picture 11

This sums it up. In case I’ve forgotten to mention something, or you have any corrections, or additions, use the comment section below.

7. My shopping recommendations

On-line shopping (Amazon affiliate links):

Amazon affiliate link

Amazon affiliate link

Help BikeGremlin

stay online & independent

This website is educational, free, objective, and not commercial

(sponsors don’t enjoy paying if you mention all the product downsides that you notice 🙂 ).

How much does a WordPress website cost?

If you find this site to be good and helpful,

and if $5 per month is what you can afford to set aside,

please consider supporting my work with a Patreon donation:

The existing comments posted under this article (questions and answers) have been moved to this BikeGremlin forum thread:

https://www.bikegremlin.net/threads/bicycle-shifter-brake-cable-and-housing-standards-article-comments.128/

“shifter housing, not cables?”

Yes, I meant housing.

Relja, your postings are on point!!!

Normally, my competency for cable work makes the process enjoyable, save for the time I used my only record of the closed form solution to elliptical integrals I’d just derived, written on two $100 bills, folded up to make a spacer for the rear brake rotor & piston, and forgetting to remove them before taking a test ride on a very windy day. I strongly discourage the use of graph theory & currency as a brake block no matter how perfect the idea may seem.

For shifting precision, I think the important ratio is the center-to-center distance of the cog spacing vs. the total cable pull to move the derailleur over that distance.

(center-to-center distances below are only Shimano/SRAM compatible ones, pulled from Sheldon Brown’s classic spacing crib sheet)

For old Shimano 1:1.7 actuation ratio:

5/6-speed: 5.50/1.7 = 3.24 mm of cable pull to shift

7-speed: 5.00/1.7 = 2.94 mm of cable pull to shift

8-speed: 4.80/1.7 = 2.82 mm of cable pull to shift

9-speed: 4.34/1.7 = 2.55 mm of cable pull to shift

10-speed: 3.95/1.7 = 2.32 mm of cable pull to shift

As cog spacing decreased, the amount of cable pull per shift also decreased, and the slight error or play introduced by spiral-wound cable housing became a problem for the shifting precision. However for SRAM’s standard “1:1” actuation ratio, even for 10-speed cassette spacing the amount of cable pull per shift is larger than the old 5/6-speed standard using a 1:1.7 actuation ratio:

For SRAM 1:1.1 actuation ratio:

7-speed: 5.00/1.1 = 4.55 mm of cable pull to shift

8-speed: 4.80/1.1 = 4.36 mm of cable pull to shift

9-speed: 4.34/1.1 = 3.95 mm of cable pull to shift

10-speed: 3.95/1.1 = 3.59 mm of cable pull to shift

In my experience with SRAM 9-speed, this very long cable pull per shift makes it possible to use the very durable and more flexible spiral-wound brake cable housing and still have crisp shifting. i.e. any play it introduces seems to be within the acceptable error margin. After all, the rear derailleur jockey pulley also has slight side-to-side float to allow the chain to center itself on the cog once the shift is accomplished. I have not tried this setup with full-length housing, only with more traditional frames where some 2/3 of the shift cable runs between cable housing stops on the frame, keeping the total housing length fairly short.

I have also used brake housing (and spiral-wound Shimano SP40 SIS shifter housing) with Shimano setups using 1:1.7 actuation, but in that case the shifting quality is definitely degraded. For the setups I have built, it usually works acceptably up to 8-speed cog spacing, but success is partly dependent on the exact setup (i.e. how closely does the jockey pulley follow the cassette profile as it shifts).

My guess is that this progressive degradation in shifting quality with reduced cog spacing is a significant part of the reason that Shimano changed the actuation ratios of their shift mechanisms in the most recent iterations. It is a good solution to the root problem, and I find it funny that in the most extreme case they have arrived at essentially the same actuation ratio as the SRAM “1:1” design.

Hi Aaron,

Very nicely explained and I completely agree.

Yes, it is ironic how it took Shimano “only” a decade or so to reach the same “conclusion” that SRAM did. 🙂

Relja Novovic