This is a list of recommended bicycle parts tightening torques that have worked well for me so far. Briefly put, I’m answering the question: “how much should I tighten the bolts on my bicycle?“

A separate article explains the recommended bicycle maintenance service intervals.

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

Follow manufacturers’ instruction – this list is primarily for my own reference and I’ll take no responsibility for any readers using it.

Table Of Contents (T.O.C.):

- What is a tightening torque?

- Recommended bicycle part tightening torques

2.1. Frame, seatposts, saddles, stems

2.2. Handlebars and levers

2.3. Wheels, cassettes, hubs

2.4. Brakes

2.5. Derailleurs

2.6. Bottom brackets

2.7. Pedals, cranks, front chainrings - Gates Carbon drive – belt systems

TL/DR

Here, I’ve explained how much you should tighten each bolt on your bicycle, how to measure that (before cracking your expensive carbon parts or stripping any threads), and why that is important.

1. What is a tightening torque?

And why does it matter?

When we are pushing something, we can talk about force (force, work, and power explained – video). However, tightening nuts and bolts requires some force applied in a circular direction, so there we are talking about torque.

I’ve made a video explaining what torque is:

Torque and power – basics explained

What happens when we are tightening a bolt? It stretches, acting as a kind of a rubber band, as it presses the joined parts together, creating what’s called a preload.

Too much preaload can damage a bolt, while too little preload can lead to a bolt loosening due to vibrations and other forces. In this video I’ve explained the bolted joints, and the importance of having an optimal preload and tightening torques:

Bolted connection and tightening torque basics

Now, when we are tightening a bolt, we can’t directly measure how much preload is created, but what we can measure is the tightening torque. We can feel the torque by hand, and a precise way to measure it is using torque wrenches.

In detail video about torque wrenches:

Update, November 2023:

Most of the topics from the above-linked videos are covered and explained in my article:

Tightening torque and torque wrenches explained – 101

When we apply the same torque to a lubricated bolt, it will create more preload compared to a dry, non-lubricated bolt. In the article about mounting (anti-seize) pastes, I’ve explained how the use of mounting pastes affects the recommended tightening torque. All the tightening torques shown in this article are given for joints lubricated with mounting paste.

2. Recommended tightening torque list

The torque list is logically sorted by the parts of a bicycle where the respective components are located. All the values are given with a consideration that mounting (anti-seize) paste is used.

Follow manufacturers’ instruction – this list is primarily for my own reference and I’ll take no responsibility for any readers using it.

The torques are provided in Newton-metres (N⋅m), and here’s an online N⋅m to inch-pound converter.

1 N⋅m = 8.851 x in-lb (N⋅m to inch-pounds)

1 N⋅m = 0.74 x ft-lb (N⋅m to foot-pounds)

1 ft-lb = 12 x in-lb (foot-pounds to inch-pounds)

2.1. Frame, seatposts, saddles, stems

| Component (part) | N⋅m |

|---|---|

| Threaded fork headset locknut | 15 |

| Quill-stem fixing bolt (on threaded forks) | 16 |

| Ahead (threadless) stem steering column pinch bolts * | 5 * |

| Stem to handlebars interface with 4 bolts * | 5 * |

| Stem to handlebars interface with 1 or 2 bolts * | 14 * |

| Seatpost pinch bolt * | 4 * |

| Saddle to seatpost mount * | 16 * |

Help BikeGremlin

stay online & independent

This website is educational, free, objective, and not commercial

(sponsors don’t enjoy paying if you mention all the product downsides that you notice 🙂 ).

How much does a WordPress website cost?

If you find this site to be good and helpful,

and if $5 per month is what you can afford to set aside,

please consider supporting my work with a Patreon donation:

2.2. Handlebars and levers

| Component (part) | N⋅m |

|---|---|

| Road bike STI (brake/shifter levers) | 6 |

| Flat bar brake levers | 5 |

| Flat bar shifters | 4.5 |

| MTB bar ends * | 7 * |

| Handlebars to stem mount – see chapter 2.1. |

2.3. Wheels, cassettes, hubs

| Component (part) | N⋅m |

|---|---|

| Quick-release cam | Video |

| Full axle wheel nuts | 25 |

| Cassette lockring | 35 |

| Cup-and-cone hub lockring | 12 |

| Freehub body to hub mount | 35 |

2.4. Brakes

| Component (part) | N⋅m |

|---|---|

| Road bike brake calipers to frame mount | 8 |

| V-brake and cantilever brakes | 7 |

| Disc brake caliper to frame | 7 |

| Brake pads – threaded mount (V-brake, road etc.) | 6 |

| Brake pads – smooth stud mount (old-style cantilever) | 7 |

| Disc brake pads retaining bolt | 3 |

| Disc (“rotor”) lockring mount | 40 |

| Disc (“rotor”) 6-bolt mount | 5 |

| Cable pinch bolt | 6 |

| Hydraulic hoses – olive, and caliper end mounts with 3 mm hex-key Caliper end mounts with 4 mm hex-key | 6 8 |

2.5. Derailleurs

| Component (part) | N⋅m |

|---|---|

| Front derailleur clamp | 5 |

| Front derailleur to clamp/brazed-on mount | 5 |

| Front derailleur shifter cable pinch bolt | 5 |

| Rear derailleur hanger to frame | 5 |

| Rear derailleur to hanger | 8 |

| Rear derailleur shifter cable pinch bolt | 5 |

| Rear derailleur pulley wheel bolt | 3 |

2.6. Bottom brackets

| Component (part) | N⋅m |

|---|---|

| Cup-and-cone cups – right | 30 |

| Cup-and-cone cups – left, locknut | 25 |

| Square-taper, Octalink, ISIS, and Power Spline cartridges | 50 |

| Hollowtech II cups | 40 |

| Campagnolo Ultra-Torque cups | 50 |

2.7. Pedals, cranks, front chainrings

| Component (part) | N⋅m |

|---|---|

| Pedals into cranks | 35 |

| Square taper, Octalink, ISIS, and Power Spline crank mounting bolts | 40 |

| Race Face right crank mounting bolt | 50 |

| Hollowtech II, and FSA MegaExo left crank mounting cap | 1.5 |

| Shimano left crank mounting bolt on BBs with adjustable preload (like XTR M9100) | 45 |

| Hollowtech II, and FSA MegaExo left crank pinch bolts | 11 |

| Race Face right crank cap for self-extraction | 15 |

| Chainring mounting bolt – steel | 12 |

| Chainring mounting bolt – aluminium | 8 |

| Chainrings with a lockring mounting system (like cassettes) | 40 |

3. Gates Carbon drive – belt systems

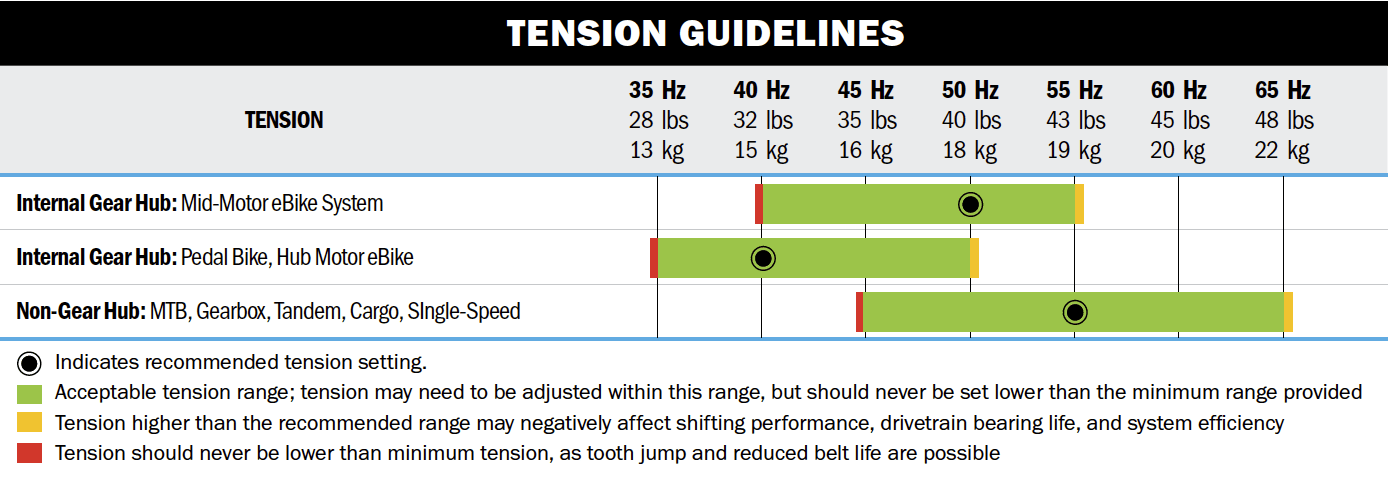

Here is a chart with optimal belt tensions:

This is a tool suitable for measuring the tension:

Here is where you can buy this tool (Germany, where else? 🙂 )

If you have any questions (or additions and corrections), please use the BikeGremlin forum:

www.bikegremlin.net

Relja, is there any, or specific, reason you did not discuss “dial gauge” torque wrenches? Given all things equal (care and maintenance) do you have an opinion regarding the use dial gauge torque wrenches over “click” type wrenches? I assume click will inherently go out of calibration easier and faster, due to internal design, than dial gauge units.

Hi Christian,

Well noticed. 🙂

Those are not very popular among mechanics in my city – I suppose the local pricing and availability of remotely-decent ones plays a big part in that (very few bike shops have any kind of torque wrench for that matter). Out of sight – out of mind as they say. It’s a mistake on my part for overlooking to discuss and explain the pros and cons.

If I manage to source one for demonstration, I’ll make a follow-up video on dial gauge torque wrenches.

Relja

Hi Christian,

I have a Contoura AL12 bike with a Gates Carbon Drive. The belt temsion is adjusted by slackening 2 sets of allen bolts which then allow the wheel to move backwards or forwards accordingly.

I cannot find a torque setting for these bolts anywhere, can yo help please?

Kind regards

Phil

Hi Phil,

I’ve added the “section 3” in the article with information for the Gates Carbon Drive systems.

Hope that helps.

Relja